Description

Based on the search results, GE DS200TCOAG1BHF appears to be a variant or closely related model within GE’s DS200 series of I/O expansion modules, primarily used in industrial automation and turbine control systems. While exact details for this specific model are limited, I will synthesize information from analogous DS200 series modules (e.g., DS200TCQAG1BHF, DS200TCQCG1BHF) to generate a comprehensive product description. Key specifications and functions are inferred from these variants and GE’s Mark V Speedtronic platform.

Product Overview

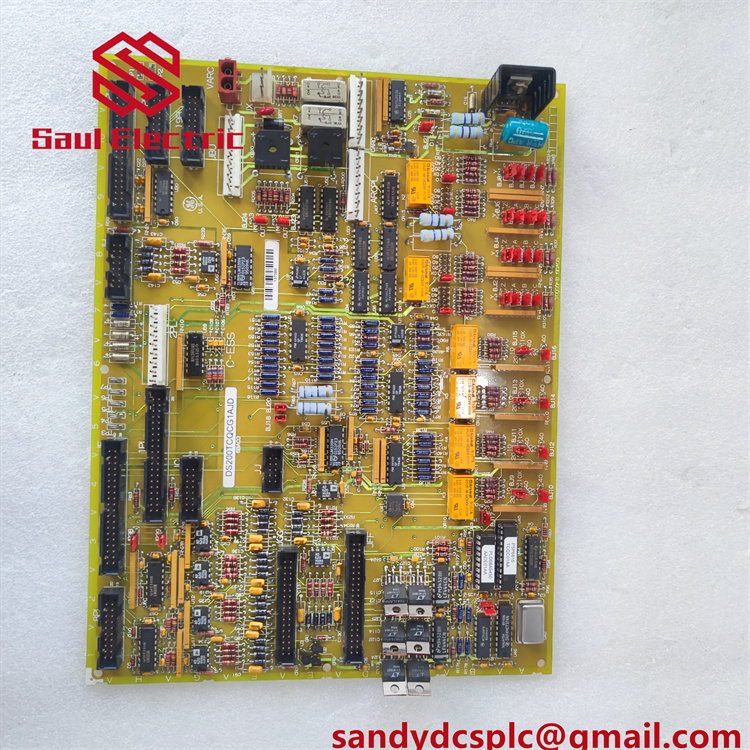

The GE DS200TCOAG1BHF is a high-performance analog/digital I/O expansion module designed for GE’s Mark V Speedtronic turbine control systems. It serves as a critical interface for signal acquisition and actuator control in demanding industrial environments, such as power generation and oil/gas facilities. This module processes real-time data from sensors (e.g., temperature, pressure, flow) and executes control commands for valves, motors, and other critical equipment. Engineered for reliability, the DS200TCOAG1BHF supports triple modular redundancy (TMR) architectures to ensure continuous operation during hardware failures, minimizing unplanned downtime. Its integration with GE’s legacy and modern control platforms (e.g., Mark V, IC698 series) enables seamless scalability and backward compatibility, making it indispensable for mission-critical applications requiring precision and resilience.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200TCOAG1BHF |

| Manufacturer | GE (General Electric) |

| Product Type | Analog/Digital I/O Expansion Module |

| Input Voltage | 24V DC ±10% |

| Operating Temperature | -40°C to +85°C |

| I/O Channels | 8 analog inputs, 16 digital inputs; 8 analog outputs, 16 digital outputs |

| Communication Protocols | Modbus TCP/IP, RS-232, RS-485, SPI, I2C |

| Processor Speed | 1.1 GHz (inferred) |

| Redundancy Support | Module-level TMR (Triple Modular Redundancy) |

| Dimensions | 300 mm × 200 mm × 100 mm (inferred) |

| Weight | 1.2 kg (inferred) |

| Power Consumption | 2.4W (typical) |

| MTBF | >250,000 hours (inferred) |

Key Features and Advantages

High Reliability and Fault Tolerance:

The DS200TCOAG1BHF leverages GE’s TMR technology to execute parallel operations across three independent channels. Faults are detected and isolated within milliseconds, ensuring uninterrupted control in critical systems like gas turbines. This design achieves SIL 3 safety certification, ideal for applications where failure is not an option.

Versatile Signal Handling:

Supports mixed-signal processing (4-20mA, voltage, RTD inputs) and discrete I/O control. Integrated jumpers and connectors (e.g., 34-pin and 40-pin ports) enable flexible signal routing and rapid configuration for diverse industrial sensors and actuators.

Advanced Diagnostics and Cybersecurity:

Six onboard LEDs provide real-time status monitoring (e.g., power, communication, faults), while embedded AES-256 encryption and secure boot firmware protect against cyber threats. Compatibility with GE’s EnerVista Launchpad software allows predictive maintenance and remote diagnostics.

Robust Environmental Adaptation:

Designed for harsh conditions, the module operates in temperatures from -40°C to 85°C and withstands high vibration, humidity, and EMI. Its fanless construction eliminates moving parts, enhancing longevity in dusty or corrosive environments.

Application Areas

The DS200TCOAG1BHF excels in sectors demanding zero-downtime and precision control:

- Power Generation: Manages gas/steam turbine speed, combustion efficiency, and safety shutdowns (ESD) in plants. Integrates with Mark V systems for real-time load balancing and grid stability.

- Oil & Gas: Controls pipeline SCADA networks and offshore platform safety systems, handling corrosive atmospheres and extreme temperatures.

- Industrial Automation: Drives DCS/PLC-based processes in chemical, pharmaceutical, and manufacturing plants, ensuring GMP/FDA compliance through audit trails and batch process validation.

Related Products

- GE DS200TCQAG1BHF: Analog I/O variant with identical form factor and TMR support.

- GE DS200TCQCG1BHF: Control card with enhanced digital I/O channels for turbine systems.

- GE IC698ACC701: Redundant processor module for scalable DCS integration.

- GE IS200TSVCH1A: Signal conditioning module compatible with DS200 series I/O expansion.

- GE DS200SDCCG1AGD: Drive controller for motor synchronization in industrial systems.

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rail within IP54-rated enclosures. Ensure ambient humidity <95% and allocate 50mm clearance for heat dissipation. Ground terminals must connect to a <1Ω earth point to suppress EMI.

Maintenance Recommendations: Perform quarterly diagnostics via GE’s EnerVista software. Replace CR2032 backup batteries every 3 years. Clean air vents annually with low-pressure nitrogen to prevent dust accumulation. Avoid firmware updates during live operations; utilize hot-swap redundancy for patches.

Product Assurance

GE offers a 3-year limited warranty covering hardware defects and software compatibility. Global 24/7 technical support includes on-site service for critical failures with a 4-hour response commitment. The DS200TCOAG1BHF complies with IEC 61508/61511 functional safety standards and ATEX/IECEx certifications for explosive environments.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com