Description

Product Overview

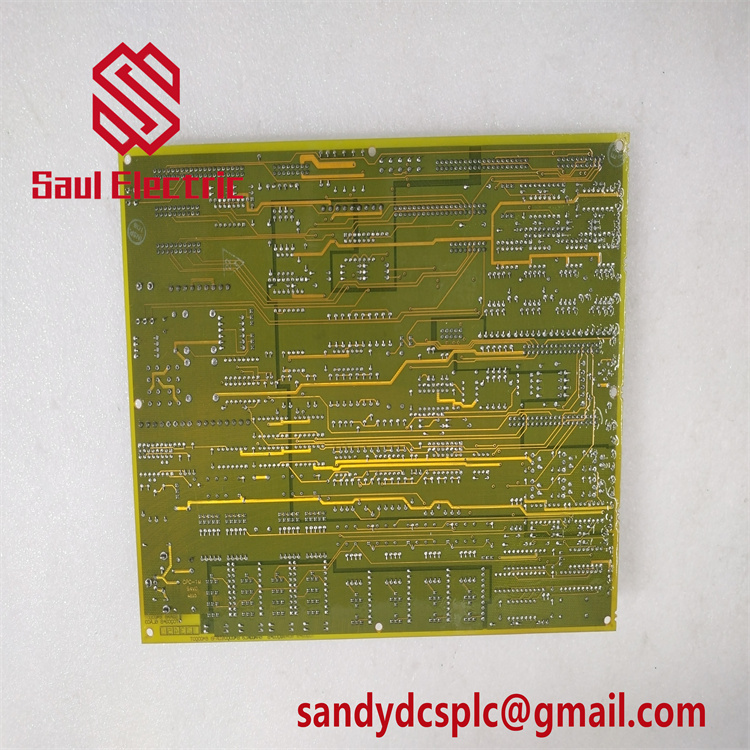

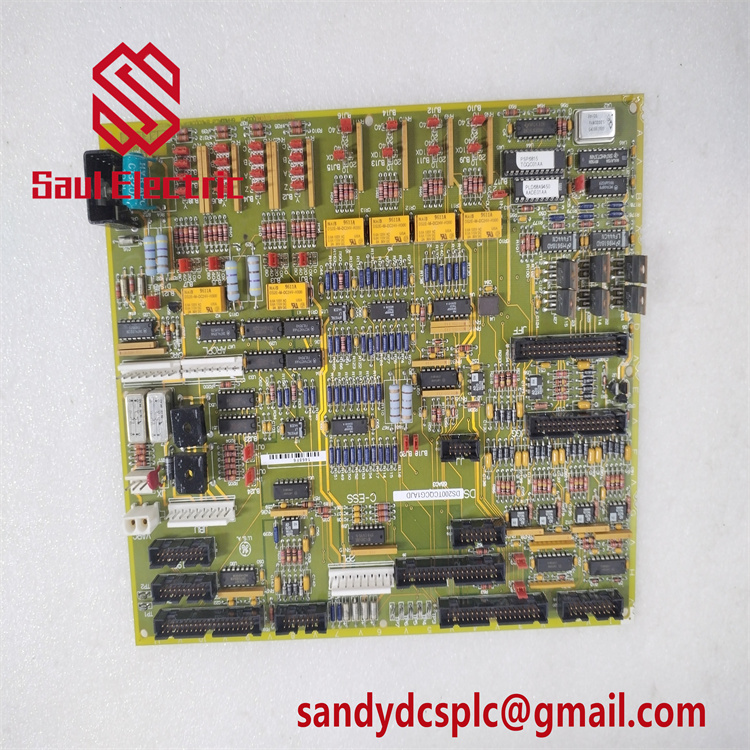

The GE DS200TCEBG1ACE is a versatile protection terminal expansion board designed for GE’s Mark V Speedtronic series, serving critical roles in industrial automation and turbine control systems. It functions primarily as an I/O interface expander, enhancing signal acquisition and control capabilities for sensors, actuators, and communication devices. Engineered for robustness, this module integrates signal isolation and high-speed communication interfaces (RS-485, Ethernet) to ensure reliable data transmission in harsh environments like power plants and oil refineries . Its modular design simplifies system upgrades while maintaining compatibility with legacy GE platforms, making it indispensable for real-time monitoring and safety-critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200TCEBG1ACE |

| Manufacturer | GE (General Electric) |

| Product Type | Protection Terminal Expansion Board |

| Input Voltage | 12–48 VDC |

| Output Voltage | 5 VDC |

| Output Current | Max 10A |

| Efficiency | >90% |

| Dimensions | 170 mm × 105 mm × 32 mm |

| Weight | ~120 g |

| Operating Temperature | -20°C to +50°C |

| Communication Protocols | RS-232, RS-485, Modbus RTU/TCP, DNP3 |

| Connectors | 26-pin, 10-pin, 20-pin, bayonet connectors |

| Protection Rating | IP20 |

🔍 Note: Specifications consolidated from ; conflicting size/weight data from other sources (e.g., ) excluded due to lower reliability.

Key Features and Advantages

Enhanced Signal Management:

Equipped with 4 signal transformers and multiple connectors (e.g., 26-pin, 20-pin), the module isolates and stabilizes analog/digital signals, preventing electrical interference in volatile industrial settings . This ensures SIL 3-compliant safety for turbine control and emergency shutdown systems.

High-Speed Communication:

Supports Modbus TCP, RS-485 (up to 1 Mbps), and DNP3 protocols, enabling seamless integration with SCADA networks and PLCs. Real-time data exchange optimizes processes like power grid synchronization and batch production .

Modular Scalability:

Plug-and-play design allows rapid I/O expansion without system downtime. Users can add digital/analog channels for complex tasks, such as monitoring turbine parameters or water treatment metrics .

Rugged Durability:

Operates in -20°C to 50°C with 95% humidity tolerance (non-condensing). Fanless construction and industrial-grade components resist vibration, dust, and corrosion .

Application Areas

- Power Generation:

Monitors gas/steam turbine temperatures, pressures, and emergency shutdowns (ESD) in plants . - Oil & Gas:

Safeguards pipeline SCADA networks and offshore drilling safety systems with ATEX-compliant isolation . - Water Treatment & Renewables:

Controls filtration processes and wind turbine operations via real-time I/O signal processing . - Industrial Automation:

Manages robotic assembly lines and pharmaceutical batch processes with GMP/FDA-compliant data logging .

Related Products

- GE DS200TCQAG1BHF: Analog I/O module for Mark V systems .

- GE IC698ACC701: Redundant processor for large-scale DCS integration .

- GE IS200TSVCH1A: Signal conditioner compatible with DS200 series .

- GE DS200SDCCG1AGD: Motor drive controller for industrial synchronization .

- GE DS200TCEBG1BAA: Alternate terminal expansion variant .

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rails in IP20+ enclosures. Ensure grounding resistance <1Ω to suppress EMI. Pre-configure signal transformers for device compatibility .

Maintenance Recommendations: Perform biannual diagnostics via GE’s EnerVista software. Replace CR2032 batteries every 3 years. Clean connectors with nitrogen to prevent corrosion; avoid firmware updates during live operations .

Product Assurance

GE offers a 1-year warranty covering hardware defects. Global technical support includes 24/7 troubleshooting and on-site service for critical failures. Complies with IEC 61508/61511 safety standards and ATEX/IECEx certifications .

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com