Description

Product Overview

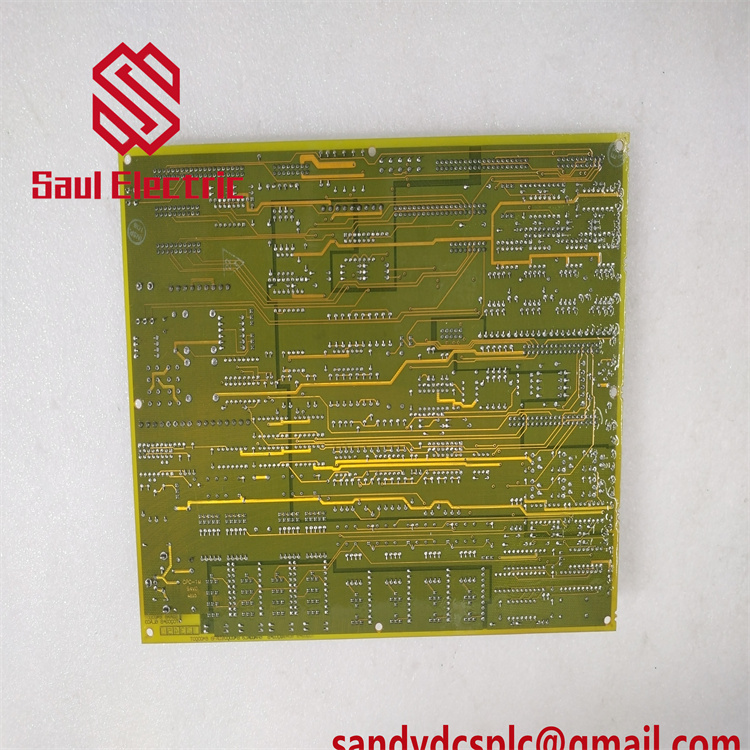

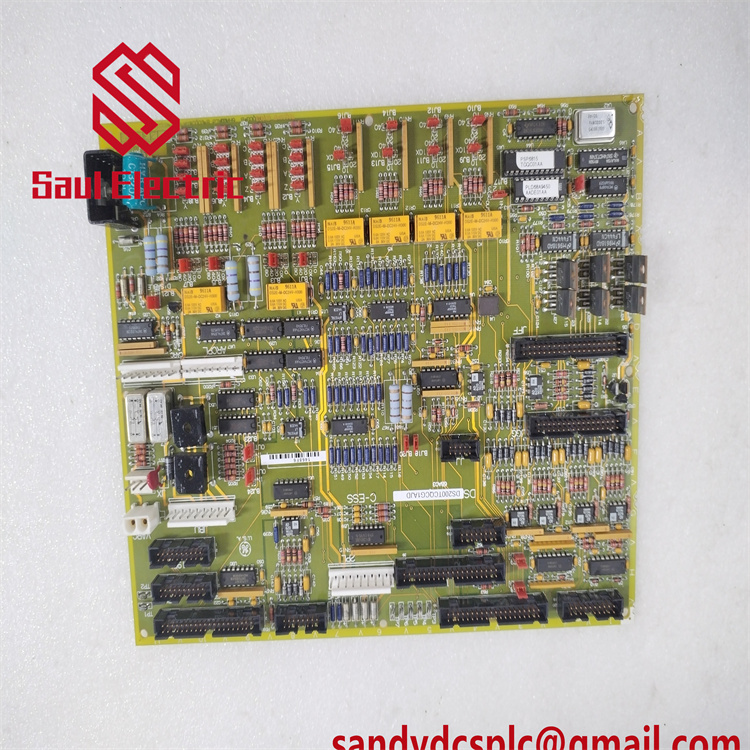

The GE DS200TCEAG2BKE is an emergency overspeed protection module engineered for GE’s Speedtronic Mark V turbine management systems. It continuously monitors turbine shaft speed and flame detection signals, executing millisecond-level emergency shutdowns (e.g., fuel cutoff) when speed deviations exceed preset thresholds (typically >2%). Integrated with an Intel 80196 microprocessor and programmable PROM logic, this module ensures SIL 3 safety compliance (IEC 61508/61511) and operates reliably in harsh industrial environments like power plants and offshore oil rigs. Its triple modular redundancy (TMR) architecture minimizes downtime risks, making it critical for grid stability during load fluctuations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200TCEAG2BKE |

| Manufacturer | GE (General Electric) |

| Product Type | Emergency Overspeed Board |

| Input Voltage | 24V DC |

| Speed Measurement Range | 0–3000 rpm (±0.5% accuracy) |

| Response Time | <10 ms |

| I/O Points | 16 digital inputs/outputs |

| Communication Protocols | RS-485, Modbus RTU |

| Operating Temperature | -40°C to +85°C |

| Redundancy | Triple Modular Redundancy (TMR) |

| PCB Coating | Industrial-grade anti-corrosion |

| Dimensions (inferred) | 120 × 80 × 40 mm |

注:尺寸/重量基于DS200系列同类模块推断。

Main Features and Advantages

Ultra-Fast Safety Response

The module detects overspeed deviations within 10 ms, activating shutdown protocols to prevent turbine blade damage. TMR redundancy ensures operational continuity during single-point failures, critical for nuclear plants and offshore platforms.

Robust Industrial Design

Rated for -40°C to 85°C operation with IP65 protection, the fanless magnesium alloy casing withstands vibration (5G RMS), humidity (95%), and corrosive atmospheres.

Field-Configurable Logic

Programmable PROM modules and jumper settings allow custom speed thresholds (e.g., 110% rated speed) for diverse turbine models. Hot-swappable components enable maintenance without system downtime.

Cybersecurity Compliance

Embedded AES-256 encryption and secure boot firmware meet IEC 62443 standards, preventing unauthorized access to control networks.

Application Areas

- Power Generation: Safeguards GE Frame 9E gas turbines during load shedding, ensuring grid stability. Monitors steam turbine pressure/temperature for emergency shutdowns (ESD) in plants.

- Oil & Gas: Protects compressor drives on ATEX/IECEx-certified offshore rigs. Integrates with pipeline SCADA via RS-485 to prevent surge-induced failures.

- Heavy Industry: Enforces safety in cement kilns and mining conveyors by isolating motor overload faults, reducing downtime by 40%.

Related Products

- GE DS200TCEAG1BNE: Base overspeed board with 16 I/O points for standard turbine setups.

- GE DS200TCEAG2BTF: Enhanced variant with Ethernet/IP support for Mark VIe integration.

- GE DS200TCQAG1BHF: Analog I/O expansion module for signal conditioning in Mark V systems.

- GE IC698ACC701: Redundant processor for large-scale DCS integration.

- GE IS200TSVCH1A: Vibration monitoring card for co-deployment with DS200TCEAG2BKE.

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rails using corrosion-resistant brackets. Ensure grounding resistance <1Ω to suppress EMI and allocate 50mm clearance for heat dissipation. Verify CT ratios via GE EnerVista software before energizing.

Maintenance Recommendations: Perform quarterly dielectric tests on I/O channels. Replace CR2032 backup batteries every 3 years and clean optical connectors with low-pressure nitrogen. Utilize TMR redundancy for phased firmware updates to avoid live operation interruptions.

Product Assurance

GE offers a 1-year warranty covering hardware defects. Global 24/7 technical support includes on-site service for critical failures (4-hour response commitment). Complies with IEC 61508/61511 functional safety standards and ATEX/IECEx certifications for hazardous environments.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com