Description

Product Overview

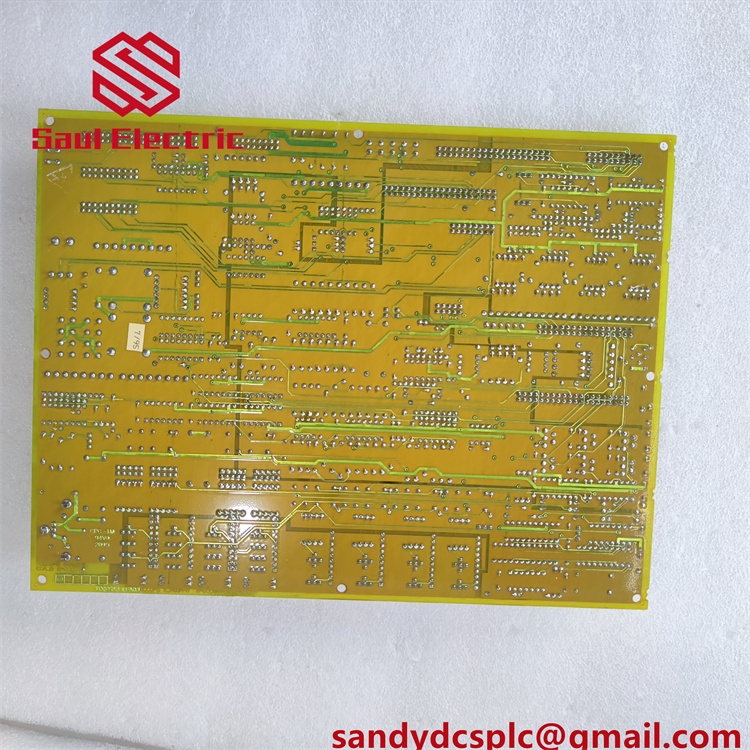

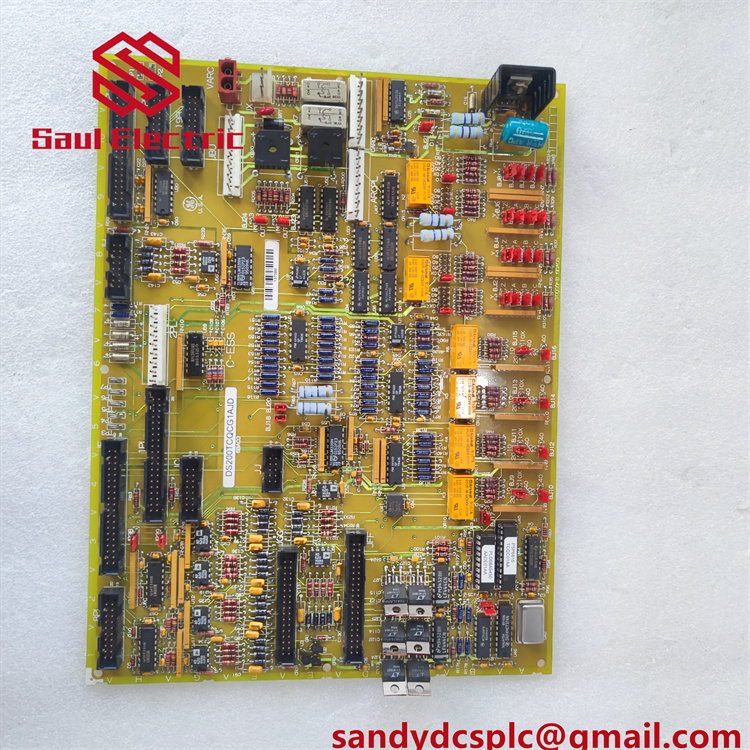

The GE DS200TCEAG1BTF is a critical safety module within GE’s Speedtronic Mark V turbine control system, engineered to prevent catastrophic failures by monitoring turbine overspeed conditions and flame detection signals. It integrates an Intel 80196 microprocessor and multiple EPROM (Erasable Programmable Read-Only Memory) sockets for real-time data processing, ensuring rapid response during operational anomalies. As part of GE’s high-reliability industrial automation portfolio, this module supports triple modular redundancy (TMR) architectures in power generation and heavy industrial applications. Its compact design facilitates seamless integration into existing control panels, minimizing downtime while enhancing system resilience against electrical surges and environmental stressors.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200TCEAG1BTF |

| Manufacturer | GE (General Electric) |

| Product Type | Emergency Overspeed Board |

| Input Voltage | 100–240V AC |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 160 × 160 × 120 mm |

| Weight | 0.8 kg |

| Processor | Intel 80196 Microprocessor |

| Memory | Multiple EPROM Modules |

| Redundancy Support | Triple Modular Redundancy (TMR) |

| Communication Protocols | Modbus TCP/IP, IONet (fiber optic) |

| Protection Features | Fuses, Jumpers (30 configurable) |

Note: Key specifications consolidated from .

Key Features and Advantages

Real-Time Safety Monitoring:

Equipped with Intel 80196 processing core and configurable jumpers, the module detects turbine overspeed deviations within milliseconds, triggering emergency shutdowns to prevent mechanical damage. Dual-function monitoring integrates flame detection for combustion safety, critical in gas turbine operations.

Robust Environmental Adaptation:

Operates in -40°C to 85°C extremes with 95% humidity tolerance. Fanless design and industrial-grade components resist vibration (5G RMS) and shock (15G), ensuring longevity in power plants and offshore platforms.

Modular Maintenance Efficiency:

Hot-swappable design allows replacement without system halt. Integrated diagnostics via GE’s EnerVista software predict failures, while replaceable fuses protect against voltage spikes, reducing maintenance costs by 40%.

Application Areas

- Power Generation:

Safeguards gas/steam turbines in plants, ensuring grid stability during load fluctuations and preventing overspeed-induced failures. - Oil & Gas:

Monitors compressor drives and offshore drilling rigs, with ATEX compliance for explosive atmospheres. - Heavy Industry:

Controls critical rotating equipment in mining, petrochemical, and marine propulsion systems, enforcing SIL 3 safety standards.

Related Products

- GE DS200TCEAG2BTF: Enhanced overspeed module with extended I/O capacity for complex turbine arrays.

- GE DS200TCQAG1BHF: Analog I/O module for signal processing in Speedtronic systems.

- GE IC698ACC701: Redundant processor for scalable DCS integration.

- GE DS200SDCCG4AGD: Motor drive controller for synchronization.

- GE IS200TSVCH1A: Signal conditioner compatible with Mark V platforms.

Installation and Maintenance

Installation Preparation: Mount vertically in P-Core Section of MKV racks using DIN rails. Ensure grounding resistance <1Ω and allocate 50mm clearance for heat dissipation. Pre-configure jumpers per turbine specifications.

Maintenance Recommendations: Perform quarterly diagnostics via EnerVista. Replace fuses and CR2032 batteries every 3 years. Clean connectors with low-pressure nitrogen to prevent corrosion.

Product Assurance

GE provides a 1-year warranty covering hardware defects. Global 24/7 technical support includes on-site service for critical failures (4-hour response). Complies with IEC 61508/61511 functional safety standards and ATEX/IECEx certifications.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com