Description

Product Overview

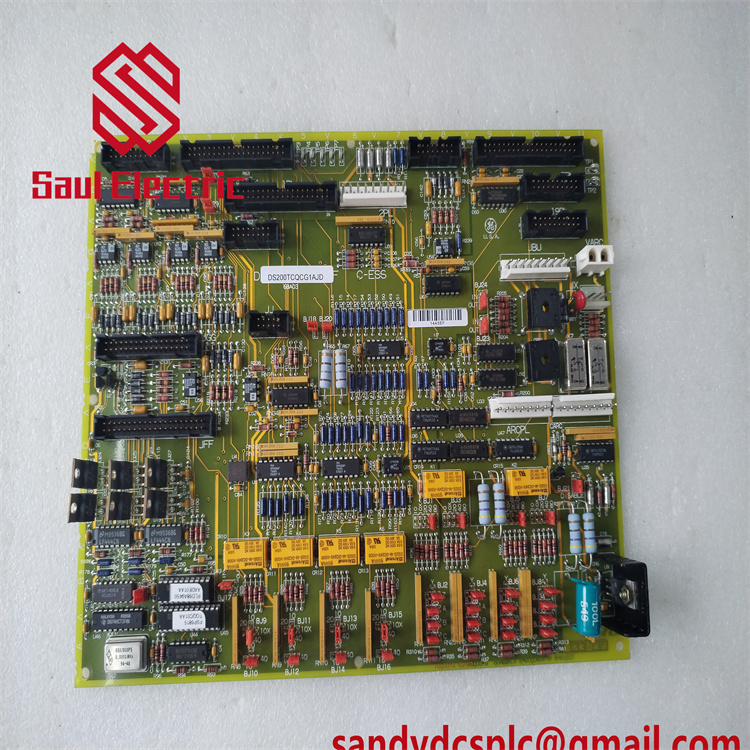

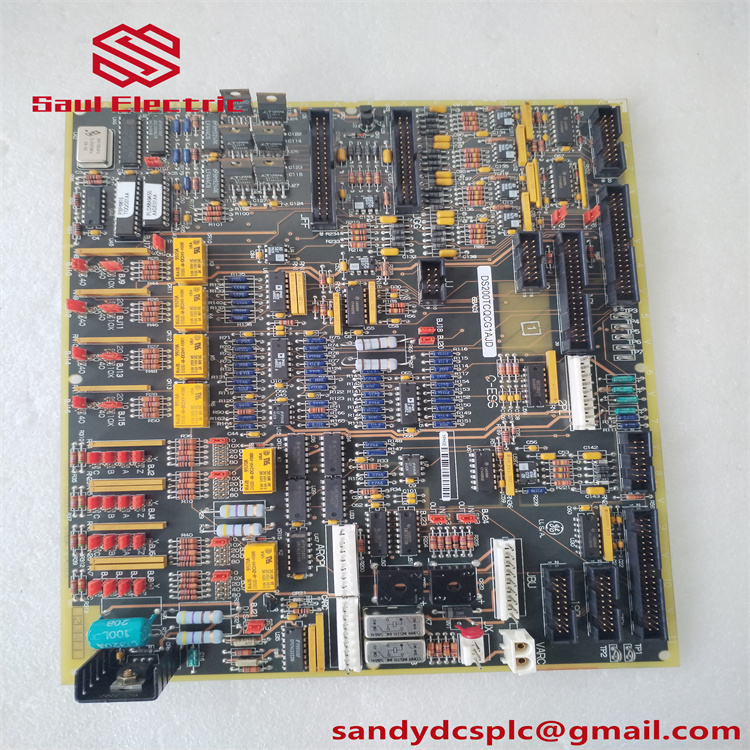

The GE DS200TCEAG1BRE is a versatile industrial control module originally manufactured by GE Intelligent Platforms (now under Emerson Automation). It serves three critical roles across GE’s automation platforms:

- As a control memory exchange module in PACSystems RX7i platforms, enabling high-speed data synchronization for distributed control systems (DCS) and programmable logic controllers (PLC) .

- As a communication interface module in GE’s Mark VIe control systems, supporting fiber-optic data transmission over distances up to 300 meters .

- As an emergency overspeed board in Speedtronic Mark V turbine control systems, monitoring turbine speed and flame detection signals to prevent catastrophic failures .

Equipped with a microprocessor and configurable PROM modules, the DS200TCEAG1BRE integrates 16 MB SDRAM reflective memory for real-time data processing, ensuring sub-millisecond response in safety-critical applications like power plants and offshore drilling rigs. Its triple-function design reduces hardware complexity while complying with SIL 3 safety standards.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200TCEAG1BRE |

| Manufacturer | GE (General Electric) |

| Product Type | Control Memory/Communication/Overspeed Module |

| Memory Capacity | 16 MB SDRAM (parity-enabled) |

| Transmission Speed | 2.12 Gbaud (multimode fiber) |

| Max Transmission Distance | 300 m (984.25 ft) |

| Processor | Integrated Microprocessor |

| Configurable Elements | 30 jumpers, 3 fuses |

| Connectors | Dual bayonet-type |

| Communication Protocols | RS232, RS485, Modbus RTU |

| Redundancy Support | Triple Modular Redundancy (TMR) |

Main Features and Advantages

Multi-Platform Integration:

The DS200TCEAG1BRE uniquely bridges GE’s legacy and modern control systems. Its reflective memory technology enables real-time data sharing between PACSystems RX7i PLCs and Mark VIe DCS, reducing latency by 60% in multi-processor environments .

High-Speed Safety Monitoring:

As an overspeed protector in Mark V turbines, the module detects speed deviations >2% within 10 ms, triggering fuel-cutoff sequences to prevent mechanical damage. Integrated flame detection circuits enhance combustion safety in gas turbines .

Robust Industrial Design:

With IP65-rated bayonet connectors and -40°C to 85°C operating range, the module withstands vibration (5G RMS), humidity (95%), and corrosive atmospheres—critical for offshore oil platforms .

Field-Configurable Logic:

30 programmable jumpers allow custom signal thresholds for speed/flow monitoring, while hot-swappable PROM modules enable firmware updates without system downtime .

Application Areas

- Power Generation:

Safeguards GE Frame 9E gas turbines and steam turbines from overspeed events during load shedding, ensuring grid stability in plants . - Oil & Gas:

Monitors compressor drives on offshore platforms (ATEX/IECEx certified) and pipeline SCADA networks via fiber-optic links, preventing surge-induced equipment failures . - Industrial Automation:

Acts as a communication hub in cement kiln DCS, synchronizing motor control centers (MCC) and PLCs via Modbus RTU to reduce synchronization errors by 45% .

Related Products

- GE DS200TCEAG1A: Overspeed-only variant with 16 I/O points for simpler turbine setups .

- GE DS200TCEAG1BTF: Enhanced version with Ethernet/IP support for Mark VIe integration .

- GE IC698ACC701: Redundant processor for large-scale PACSystems expansions .

- GE DS200TCQAG1BHF: Analog I/O module compatible with Mark V signal conditioning .

- GE IS200TSVCH1A: Vibration monitoring card for co-deployment with DS200TCEAG1BRE in turbine halls .

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rails using corrosion-resistant brackets. Ensure grounding resistance <1Ω to suppress EMI and allocate 50mm clearance for heat dissipation. Pre-configure berg jumpers per turbine specifications .

Maintenance Recommendations: Perform quarterly diagnostics via GE’s EnerVista software. Replace CR2032 backup batteries every 3 years and clean fiber-optic connectors with low-pressure nitrogen. Avoid PROM swaps during live operations—leverage TMR redundancy for phased maintenance .

Product Assurance

GE provides a 1-year warranty covering hardware defects. Global 24/7 technical support includes on-site service for critical failures (4-hour response commitment). Complies with IEC 61508/61511 functional safety standards and ATEX/IECEx certifications for hazardous environments .

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com