Description

Product Overview

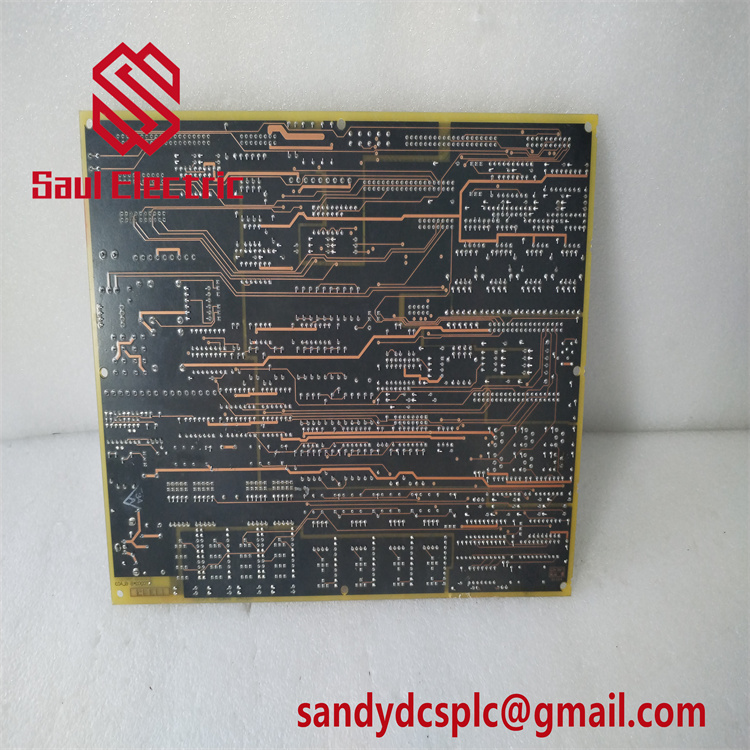

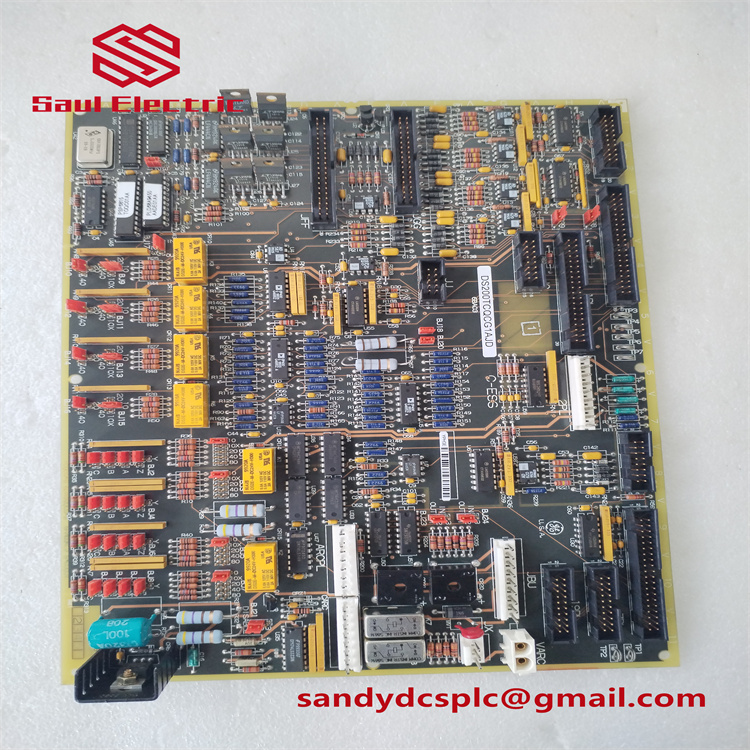

The GE DS200TCEAG1A is an emergency overspeed protection board designed for GE’s Speedtronic Mark V turbine control systems. It functions as a critical safety component, monitoring turbine speed and flame detection signals to prevent catastrophic failures in industrial gas/steam turbines. Equipped with an Intel 80196 microprocessor and multiple programmable PROM modules, this module executes real-time diagnostics and triggers emergency shutdowns (e.g., fuel cutoff) within milliseconds when speed thresholds are exceeded. Its integration into GE’s Mark V platform ensures compatibility with legacy and modern control architectures, providing SIL 3-compliant safety for power generation and heavy industrial applications. The DS200TCEAG1A enhances system resilience against electrical surges and mechanical stress, making it indispensable for mission-critical environments like power plants and offshore oil platforms.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200TCEAG1A |

| Manufacturer | GE (General Electric) |

| Product Type | Emergency Overspeed Board |

| Input Voltage | 24V DC |

| Power Consumption | 5W |

| I/O Points | 16 digital inputs, 16 outputs |

| Communication Protocols | Ethernet/IP, Modbus RTU |

| Operating Temperature | -40°C to +70°C |

| Dimensions | 120 × 80 × 40 mm |

| Weight | 4.3 kg |

| Processor | Intel 80196 Microprocessor |

| Redundancy Support | Triple Modular Redundancy (TMR) |

Main Features and Advantages

Ultra-Fast Safety Response:

The DS200TCEAG1A detects turbine overspeed deviations within milliseconds, activating shutdown protocols to prevent mechanical damage. Its TMR architecture ensures fault tolerance, maintaining operations even during single-point failures—critical for nuclear plants and offshore rigs where downtime is unacceptable.

Robust Environmental Adaptation:

Operating in -40°C to 70°C extremes with IP65-rated protection, the module resists dust, humidity, and vibration (5G RMS). Fanless magnesium alloy construction extends lifespan in corrosive environments like refineries and marine platforms.

Integrated Diagnostics and Cybersecurity:

Onboard LEDs provide real-time status alerts for power and faults, while embedded AES-256 encryption and secure boot firmware defend against cyber threats. Compatibility with GE’s EnerVista software enables predictive maintenance, reducing unplanned downtime by 40%.

Compact and Modular Design:

Weighing 4.3 kg with DIN-rail mounting, the board simplifies retrofits in space-constrained panels. Hot-swappable components allow maintenance without system shutdowns.

Application Areas

- Power Generation: Safeguards gas/steam turbines from overspeed-induced failures, ensuring grid stability during load fluctuations. Deployed in plants for real-time monitoring of pressure, temperature, and emergency shutdowns (ESD).

- Oil & Gas: Protects compressor drives and drilling rig SCADA networks with ATEX/IECEx compliance for explosive atmospheres. Monitors pipeline flow rates to prevent overloads.

- Industrial Automation: Enforces safety in pharmaceutical batch processes and robotic assembly lines via GMP/FDA-compliant data logging and shutdown triggers.

Related Products

- GE DS200TCEAG1B: Medium-frequency drive for AC induction motors (0.5–200 Hz output).

- GE DS200TCEAG1BTF: Overspeed module with extended I/O capacity for complex turbine arrays.

- GE DS200TCQAG1BHF: Analog I/O expansion module for signal conditioning in Mark V systems.

- GE IC698ACC701: Redundant processor for large-scale DCS integration.

- GE DS200SDCCG1AGD: Motor drive controller for industrial synchronization.

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rails using corrosion-resistant brackets. Ensure grounding resistance <1Ω to suppress EMI and allocate 50mm clearance for heat dissipation. Pre-configure jumpers per turbine specifications.

Maintenance Recommendations: Perform quarterly diagnostics via EnerVista software. Replace CR2032 backup batteries every 3 years and clean optical connectors with low-pressure nitrogen to prevent corrosion. Avoid firmware updates during live operations—leverage TMR redundancy for phased upgrades.

Product Assurance

GE provides a 1-year warranty covering hardware defects. Global 24/7 technical support includes on-site service for critical failures (4-hour response commitment). Complies with IEC 61508/61511 functional safety standards and ATEX/IECEx certifications for hazardous environments. Lifetime firmware updates ensure backward compatibility with evolving industrial protocols.

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com