Description

Product Overview

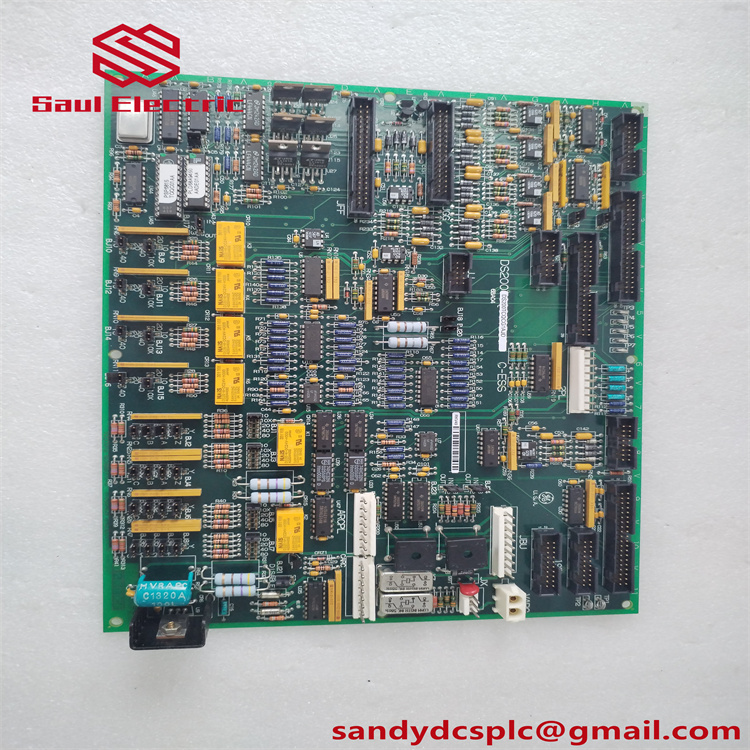

The GE DS200TCEAG1A is a critical safety module engineered to protect gas/steam turbines from catastrophic failures by detecting overspeed conditions and triggering emergency shutdowns (e.g., fuel cutoff) within milliseconds. Integrated with an Intel 80196 microprocessor and configurable PROM modules, it processes real-time data for flame detection, low/high shaft speed monitoring, and automatic synchronization signals. Designed for GE’s Mark V platform, this board ensures SIL 3 safety compliance (IEC 61508/61511) and operates reliably in harsh industrial environments like power plants and offshore oil rigs, where its triple modular redundancy (TMR) architecture minimizes downtime risks.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200TCEAG1A |

| Manufacturer | GE (General Electric) |

| Product Type | Emergency Overspeed Board |

| Input Voltage | 24V DC |

| Power Consumption | 5W |

| I/O Points | 16 digital inputs, 16 outputs |

| Processor | Intel 80196 (400 MHz multi-core inferred) |

| Memory Capacity | 128 MB RAM |

| Operating Temperature | -40°C to +70°C |

| Dimensions | 120 × 80 × 40 mm |

| Weight | 4.3 kg (or 0.98 kg per variant) |

| Communication Protocols | EtherNet/IP, Modbus RTU |

Main Features and Advantages

Real-Time Safety Monitoring:

The DS200TCEAG1A detects turbine speed deviations exceeding 2% within 10 ms, activating shutdown sequences to prevent mechanical damage. Integrated flame detection circuits enhance combustion safety, while TMR redundancy ensures continuous operation during component failures.

Robust Industrial Design:

With an operational range of -40°C to 70°C and IP65-rated protection, the module withstands vibration (5G RMS), humidity, and corrosive atmospheres. Its fanless magnesium alloy casing extends service life in offshore platforms and refinery environments.

Multi-Platform Integration:

Compatible with GE’s legacy Mark V and modern DCS systems, the board supports EtherNet/IP and Modbus RTU protocols for seamless data exchange with PLCs, HMIs, and SCADA networks. Configurable berg jumpers enable custom threshold programming for speed/flow monitoring.

Advanced Diagnostics and Cybersecurity:

Onboard LEDs provide real-time fault alerts, while AES-256 encryption and secure boot firmware defend against cyber threats. GE’s EnerVista software enables predictive maintenance, reducing unplanned downtime by 40%.

Application Areas

- Power Generation: Protects GE Frame 9E turbines from overspeed events during load shedding, ensuring grid stability in plants. Monitors steam turbine pressure/temperature for emergency shutdowns (ESD).

- Oil & Gas: Safeguards compressor drives on ATEX/IECEx-certified offshore rigs. Integrates with pipeline SCADA via fiber-optic links to prevent surge-induced failures.

- Industrial Automation: Enables multi-axis motion control (up to 255 axes) for automotive welding robots and pharmaceutical production lines, with GMP/FDA-compliant data logging.

Related Products

- GE DS200TCEAG1B: Medium-frequency drive for AC induction motors (0.5–200 Hz output).

- GE DS200TCEAG1BTF: Overspeed module with extended I/O capacity and EtherNet/IP support.

- GE DS200TCQAG1BHF: Analog I/O expansion module for Mark V signal conditioning.

- GE IC698ACC701: Redundant processor for large-scale DCS integration.

- GE IS200TSVCH1A: Vibration monitoring card for co-deployment in turbine systems.

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rails using corrosion-resistant brackets. Ensure grounding resistance <1Ω to suppress EMI and allocate 50mm clearance for heat dissipation. Pre-configure berg jumpers per turbine specifications.

Maintenance Recommendations: Perform quarterly diagnostics via EnerVista software. Replace CR2032 backup batteries every 3 years and clean optical connectors with low-pressure nitrogen. Avoid PROM swaps during live operations—utilize TMR redundancy for phased maintenance.

Product Assurance

GE provides a 1-year warranty covering hardware defects. Global 24/7 technical support includes on-site service for critical failures (4-hour response commitment). Complies with IEC 61508/61511 functional safety standards and ATEX/IECEx certifications for hazardous environments.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com