Description

Product Overview

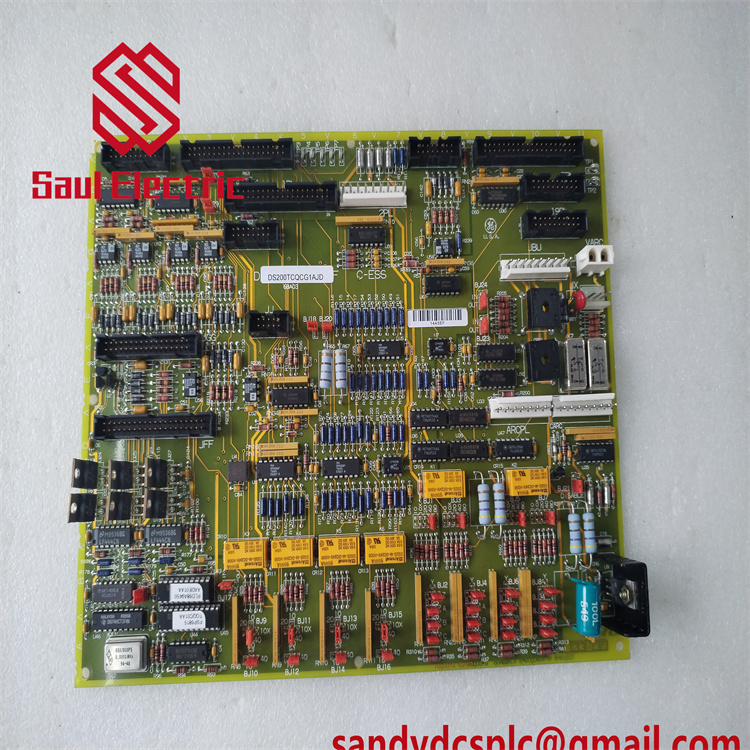

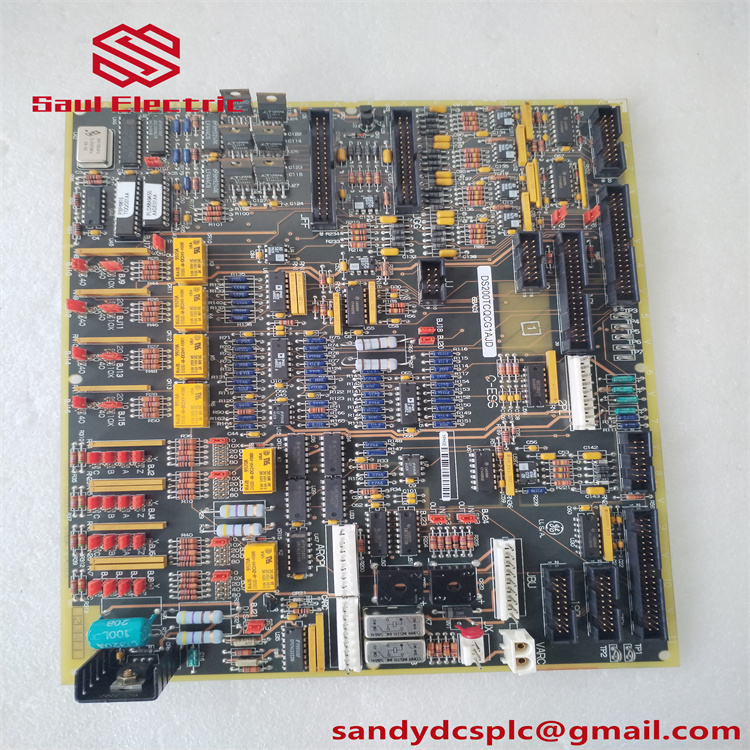

The GE DS200TCCAG1B is a high-performance Analog Input/Output (I/O) Module designed for GE’s Mark V Turbine Control System, a legacy platform widely used in power generation and industrial automation. As a TC2000-series common analog I/O board, it serves as a critical interface between field sensors/actuators and the control system, enabling precise monitoring and regulation of turbine operations. With support for 4-20 mA signals, RTDs, thermocouples, and shaft voltage/current inputs, the DS200TCCAG1B ensures reliable data acquisition and control in harsh industrial environments. Its 80196 microprocessor and programmable logic device (PLD) facilitate real-time signal conditioning, while removable PROM modules allow firmware updates without replacing the entire board12.

Integrated into the R5 core of the Mark V system, the DS200TCCAG1B interfaces with terminal boards like CTBA, TBQA, and TBCA to handle diverse analog signals2. Its 250 V continuous isolation protects against electrical noise, while LED indicators provide visual status feedback for troubleshooting. The module’s three hardware jumpers (J1, JP2, JP3) enable configuration of serial communication, oscillator settings, and factory testing modes12. By combining high precision (0.1% accuracy) with rugged construction, the DS200TCCAG1B delivers stable performance in applications requiring tight control over temperature, pressure, and rotational speed.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200TCCAG1B |

| Manufacturer | General Electric (GE) |

| Product Type | Analog Input/Output Module (TC2000 Series) |

| Signal Types | 4-20 mA, RTD, Thermocouple, Shaft Voltage/Current |

| Input Resolution | 16-bit |

| Output Accuracy | ±0.1% of full scale |

| Isolation Voltage | 250 V (continuous) |

| Operating Voltage | +5 V DC ±5%15 |

| Power Consumption | 1.5 W |

| Communication | Corebus (via 3PL connector) |

| Operating Temperature | -40°C to +85°C6 |

| Dimensions | 233 mm x 89 mm x 43 mm6 |

| Weight | 1.5 kg |

| Terminal Compatibility | CTBA, TBQA, TBCA (Mark V terminal boards)2 |

Main Features and Advantages

The DS200TCCAG1B stands out for its versatile signal handling and field-proven reliability. Its 8-channel analog input/output architecture supports mixed signal types, allowing simultaneous monitoring of temperature (via RTD/thermocouple) and process variables (4-20 mA). Each channel includes electrical isolation to prevent ground loops, while software-configurable scaling enables seamless integration with GE’s Proficy Logic Developer software1222. The module’s removable PROM design simplifies firmware updates: PROMs can be swapped without soldering, reducing downtime during maintenance910.

Ruggedness is a core strength: the DS200TCCAG1B withstands -40°C to +85°C temperatures and 5-95% humidity (non-condensing), making it suitable for extreme industrial settings6. Its cold junction compensation for thermocouples ensures accurate temperature readings, while scheduled output synchronization minimizes latency in time-critical applications like turbine speed control2. The module also includes fault detection for open circuits or short circuits, triggering alarms via the Mark V system’s HMI6.

Application Areas

The DS200TCCAG1B excels in turbine control systems for power plants, oil refineries, and industrial machinery. In gas turbine applications, it monitors exhaust temperature (via thermocouples), fuel flow (4-20 mA), and shaft vibration (voltage/current inputs), providing real-time data to the Mark V controller for safe and efficient operation27. The module’s 4-20 mA outputs drive actuators like fuel valves and inlet guide vanes, ensuring precise load regulation.

In process automation, the DS200TCCAG1B interfaces with pressure transmitters, flow meters, and analytical instruments in chemical plants. Its RTD inputs are ideal for monitoring reactor temperatures, while scalable I/O density reduces chassis space compared to discrete modules6. The module’s Corebus communication integrates seamlessly with GE’s Speedtronic control system, enabling centralized diagnostics and remote configuration22.

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation: Mount the DS200TCCAG1B in the Mark V system’s R5 core chassis. Connect field wiring to the CTBA or TBCA terminal boards using 22-16 AWG shielded cables. Configure jumpers J1 (enable/disable RS232), JP2 (oscillator settings), and JP3 (factory testing) per the application requirements12. Use GE-approved fuses (5×20 mm, 800 mA) to protect input channels from overcurrent.

Maintenance: Regularly inspect the module for loose connections or physical damage. Clean dust with a static-free cloth and verify LED indicators for 异常状态. To replace the board, transfer PROM modules from the old unit to the new DS200TCCAG1B using an anti-static wrist strap910. Calibrate analog inputs annually using GE’s Proficy software to maintain accuracy.

Product guarantee

GE guarantees the DS200TCCAG1B with a 1-year warranty covering defects in materials and workmanship. Customers receive 24/7 technical support for configuration, troubleshooting, and firmware updates. The module undergoes rigorous testing to meet IP65 standards for dust and moisture resistance56. For urgent replacements, DS200TCCAG1B units are available from stock, with delivery within 3 days after payment.

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com