Description

Product Overview

The GE DS200TBOFG1A is a high-performance analog output termination module engineered for seamless integration with GE’s Speedtronic Mark V turbine control system, a cornerstone of industrial automation in power generation, oil & gas, and heavy industry. As part of the RST (Remote Signal Termination) series, the GE DS200TBOFG1A serves as a critical interface between the Mark V controller and field devices (actuators, valves, transducers), enabling precise signal conditioning, transmission, and isolation in harsh operational environments.

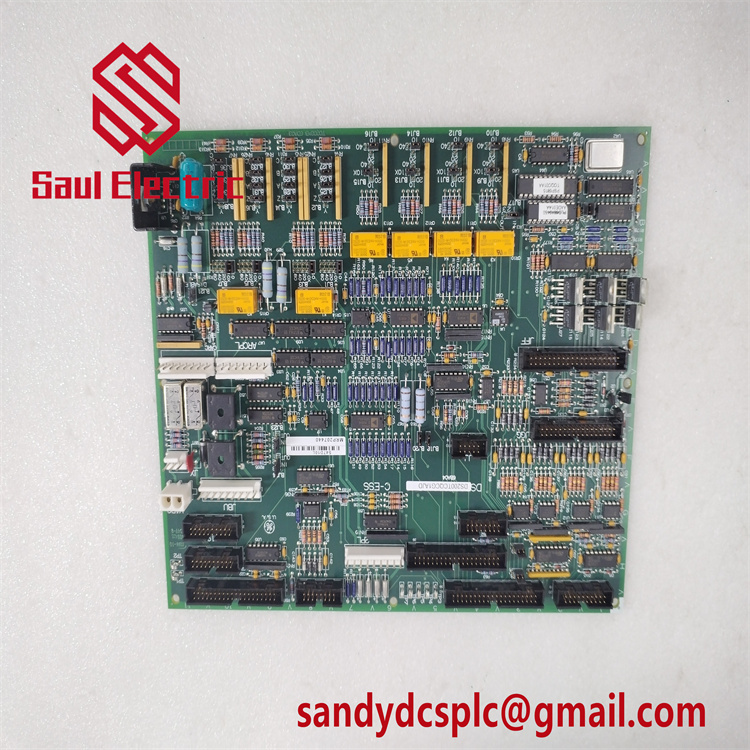

Designed to handle 4-20 mA analog outputs and discrete digital signals, the GE DS200TBOFG1A ensures compatibility with core Mark V modules like the DS200TCCAG1B (analog I/O) and DS200TCEAG1B (power supply). Its dual 90-pin terminal blocks support up to 180 signal connections, while configurable jumpers allow field technicians to scale voltage/current outputs without hardware modifications. The module’s 34-pin connectors (JGR, JHR, JGS/T) facilitate secure communication with the Mark V controller, ensuring real-time data exchange for turbine speed regulation, fuel control, and safety interlocks.

Built with industrial-grade components and a multilayer PCB design, the GE DS200TBOFG1A delivers robust immunity to electromagnetic interference (EMI) and high vibration, making it ideal for turbine halls, offshore platforms, and other extreme environments. With 250 V continuous isolation and a wide -40°C to +85°C operating range, this module ensures stable performance in mission-critical applications where downtime is costly.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200TBOFG1A |

| Manufacturer | General Electric (GE) |

| Product Type | Analog Output Termination Module (RST Series) |

| Signal Types | 4-20 mA analog, discrete digital |

| Terminals | 180 (2 blocks × 90 terminals) |

| Jumpers | Configurable for signal scaling/type selection |

| Connectors | 3 × 34-pin (JGR, JHR, JGS/T), 2 × 20-pin (ribbon cable) |

| Isolation Voltage | 250 V (continuous) |

| Operating Temperature | -40°C to +85°C |

| PCB Coating | Standard conformal coating |

| Dimensions | 160 mm × 160 mm × 120 mm |

| Weight | 1.35 kg |

| Compatibility | GE Mark V core modules (e.g., DS200TCCAG1B, DS200TCEAG1B) |

Main Features and Advantages

The GE DS200TBOFG1A stands out for its precision and reliability in delivering analog output signals for turbine control systems. Its dual 90-pin terminal blocks simplify wiring by consolidating analog and digital signals into a single module, reducing panel space and installation complexity. The configurable jumpers allow technicians to adapt the module to diverse field devices—such as solenoid valves (24 VDC) or proportional actuators (4–20 mA)—without replacing hardware, enhancing flexibility in retrofit projects.

Reliability is a cornerstone of the GE DS200TBOFG1A: its 250 V isolation prevents ground loops and signal degradation, while test points enable quick diagnostics without disconnecting field wiring. The module’s hot-swap capability further minimizes downtime, allowing replacement of faulty units without powering down the entire Mark V system—a critical feature for 24/7 operations.

Engineered for extreme conditions, the GE DS200TBOFG1A incorporates IP65-rated dust and moisture resistance and a vibration-resistant design, ensuring consistent performance in high-noise environments. Its removable connectors and color-coded terminal labels streamline maintenance, while GE’s Proficy software supports remote calibration and monitoring, optimizing system efficiency.

Application Areas

The GE DS200TBOFG1A is widely deployed in gas and steam turbine control systems, where it interfaces with critical components like:

- Fuel control valvesto regulate fuel flow during start-up, load changes, and shutdowns.

- Inlet guide vanes (IGVs)to optimize airflow and turbine efficiency.

- Hydraulic actuatorsfor precise control of mechanical systems.

- Solenoid valvesfor safety interlocks and emergency shutdowns.

Beyond turbines, the module excels in process automation for refineries, chemical plants, and power generation facilities. It drives discrete outputs to control pumps, compressors, and other auxiliary equipment, while its 4-20 mA analog outputs enable precise regulation of process variables like pressure and temperature. By integrating with GE’s Speedtronic system, the GE DS200TBOFG1A enables centralized control and diagnostics, reducing operational costs and improving system responsiveness.

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation: Mount the GE DS200TBOFG1A in the Mark V system’s R5 core chassis, ensuring proper grounding to minimize EMI. Connect field wiring (22–16 AWG shielded cables) to the dual terminal blocks, following the terminal assignments in GE’s GEI-100168 manual. Configure jumpers based on signal type (e.g., analog output vs. discrete) and device specifications. Use GE-approved 5×20 mm fuses (800 mA) to protect output channels from overcurrent.

Maintenance: Regularly inspect the GE DS200TBOFG1A for loose connections or corrosion. Clean dust with a static-free cloth and verify LED status indicators for 异常状态. When replacing the module, transfer connectors using an anti-static wrist strap to prevent ESD damage. Calibrate analog outputs annually using GE Proficy software to maintain ±0.1% accuracy.

Product 保障

GE backs the GE DS200TBOFG1A with a 1-year warranty covering defects in materials and workmanship. Customers receive 24/7 technical support for configuration, troubleshooting, and firmware updates, ensuring seamless integration into Mark V systems. The module undergoes rigorous testing to meet industrial standards for vibration, temperature, and electromagnetic compatibility. For urgent needs, GE DS200TBOFG1A units are available from stock, with delivery within 3 days of payment, minimizing operational disruptions.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com