Description

Product Overview

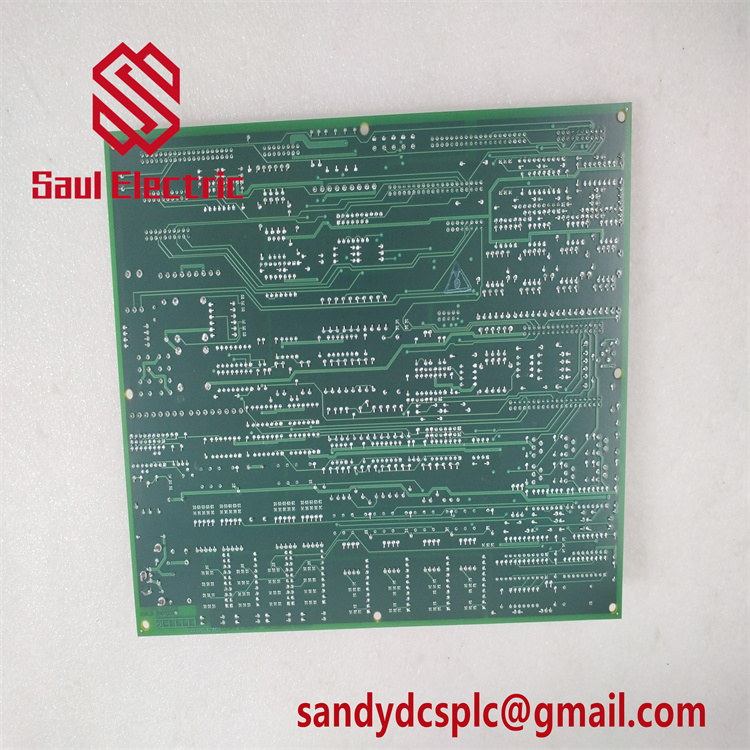

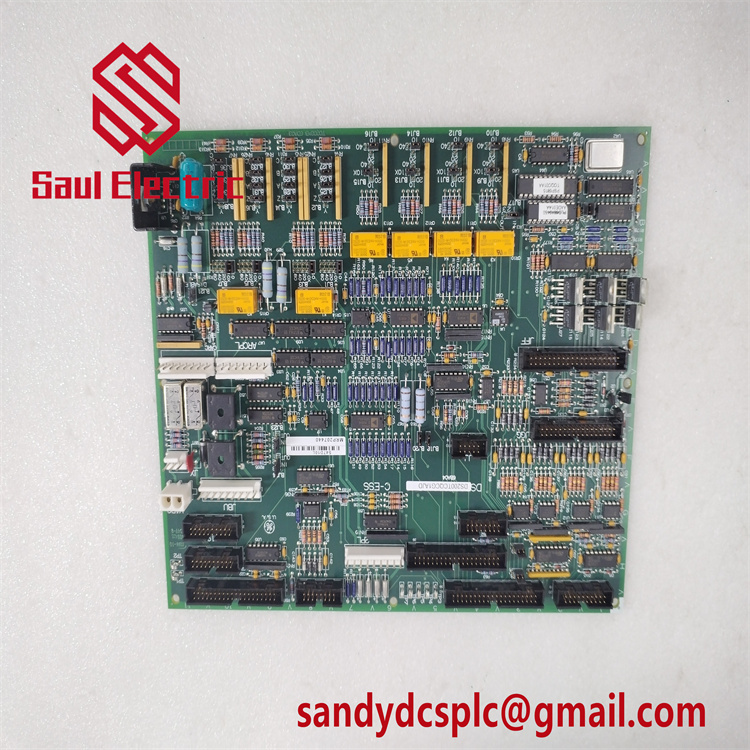

The GE DS200TBCBGIAAA is a high-performance control module belonging to GE’s renowned Mark VIe series, a flagship platform in industrial automation systems. Designed to deliver precise and reliable control capabilities, GE DS200TBCBGIAAA integrates advanced processing power with robust I/O management, making it a critical component in complex industrial control architectures.

As a key part of the Mark VIe system, GE DS200TBCBGIAAA excels in real-time data processing, enabling seamless communication between various system components to ensure synchronized operation. Its modular design allows for easy integration into existing setups, enhancing system flexibility and scalability. Whether deployed in standalone configurations or as part of a larger network, GE DS200TBCBGIAAA provides the stability and performance required to optimize industrial processes, reduce downtime, and improve overall operational efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200TBCBGIAAA |

| Manufacturer | GE |

| Product Type | Control Module (Mark VIe Series) |

| Operating Voltage | 24V DC ±10% |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Communication Protocols | Ethernet/IP, Modbus TCP/IP |

| I/O Interfaces | 8 digital inputs, 6 digital outputs |

| Dimensions (L x W x H) | 150mm x 100mm x 50mm |

| Weight | Approx. 0.5kg |

| Mounting Type | DIN rail or panel mount |

| MTBF (Mean Time Between Failures) | >100,000 hours |

Main Features and Advantages

The GE DS200TBCBGIAAA stands out for its exceptional reliability, a hallmark of GE’s engineering excellence. Its ruggedized design ensures stable operation even in harsh industrial environments with high vibration, temperature fluctuations, and electrical noise, minimizing the risk of unplanned shutdowns.

Equipped with advanced processing cores, GE DS200TBCBGIAAA delivers rapid data processing speeds, enabling real-time response to system changes and ensuring precise control over connected equipment. The module’s compatibility with multiple communication protocols simplifies integration with diverse industrial systems, reducing setup time and operational complexity.

Another key advantage is its modular architecture, which allows for easy upgrades and maintenance without disrupting the entire system. This flexibility makes GE DS200TBCBGIAAA adaptable to evolving industrial needs, from small-scale operations to large, complex facilities. Additionally, built-in diagnostic features facilitate quick troubleshooting, further enhancing system uptime and reducing maintenance costs.

Application Fields

The GE DS200TBCBGIAAA finds extensive application in industries requiring robust and precise control systems. In power generation, it is widely used in turbine control systems, where it manages critical operations such as speed regulation, load balancing, and safety interlocks, ensuring efficient and safe power production.

In the oil and gas sector, GE DS200TBCBGIAAA plays a vital role in upstream and downstream processes, controlling pumps, compressors, and refining equipment to maintain optimal operational parameters. Its reliability is particularly valuable in offshore platforms, where equipment accessibility is limited and downtime is costly.

Manufacturing facilities also benefit from GE DS200TBCBGIAAA, as it integrates seamlessly into production lines to control conveyor systems, robotic arms, and assembly machinery, enhancing process accuracy and throughput. Additionally, it is employed in water treatment plants and wastewater management systems, ensuring consistent control over filtration, pumping, and chemical dosing processes.

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation preparation: Before installing GE DS200TBCBGIAAA, ensure the mounting surface is clean, flat, and free from excessive vibration. Verify that the power supply meets the 24V DC ±10% requirement and that all communication cables are properly terminated to avoid signal interference. Check compatibility with existing Mark VIe components to ensure seamless integration, and refer to the GE installation manual for specific torque requirements for mounting hardware.

Maintenance recommendations: Regular maintenance of GE DS200TBCBGIAAA includes visual inspections for dust accumulation, which can be removed with compressed air (avoiding direct high-pressure airflow on components). Periodically check connection terminals for tightness to prevent voltage drops or signal loss. Utilize the module’s built-in diagnostic tools to run routine health checks, and schedule firmware updates in coordination with system downtime to ensure optimal performance. Store spare GE DS200TBCBGIAAA units in a dry, temperature-controlled environment to maintain readiness for quick replacement if needed.

Product Guarantee

We stand behind the quality and performance of GE DS200TBCBGIAAA with a comprehensive warranty and dedicated support services. All units undergo rigorous testing to meet GE’s strict industrial standards, ensuring reliability from the moment of installation. Our technical support team is available 24/7 to assist with installation guidance, troubleshooting, and operational queries related to GE DS200TBCBGIAAA. In the unlikely event of a defect, we offer prompt replacement or repair services to minimize downtime. With a commitment to customer satisfaction, we ensure that GE DS200TBCBGIAAA delivers consistent performance throughout its operational lifecycle, backed by our expertise in industrial automation solutions.

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com