Description

Product Overview

The GE DS200SLCCG3AFG is a LAN Communication Board designed for GE’s Mark V series of industrial control systems, a cornerstone of automation in power generation, oil & gas, and heavy machinery. As a critical component of the Speedtronic architecture, this board enables real-time data exchange between the Mark V controller and peripheral I/O modules, ensuring seamless coordination of turbine control, diagnostics, and safety interlocks.

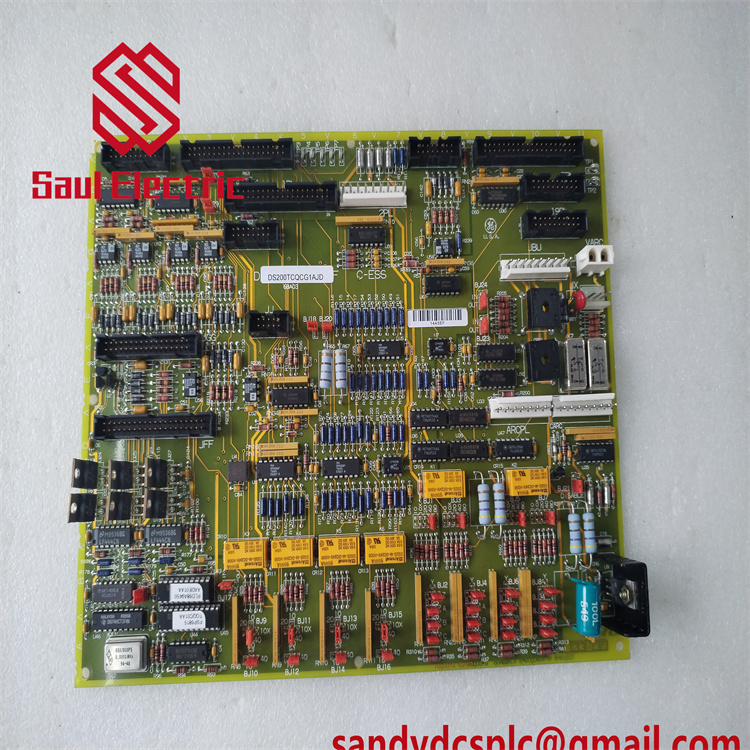

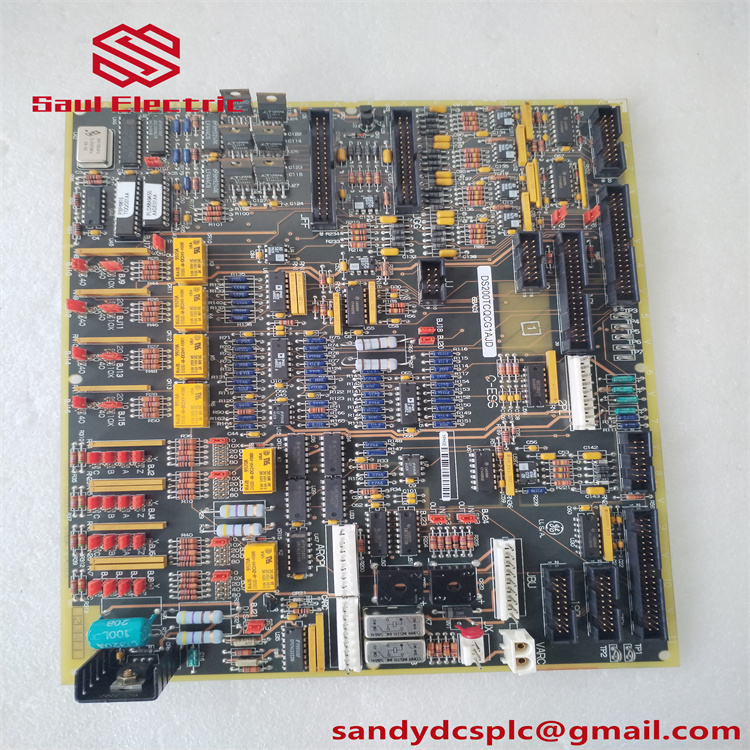

Engineered for high-performance communication, the GE DS200SLCCG3AFG supports ARCNET LAN and DLAN (Distributed LAN) protocols, allowing integration with modules like the DS200TCCAG1B (analog I/O) and DS200TCEAG1B (power supply) for distributed control. Its LAN Control Processor (LCP) filters and processes signals, while dual-port RAM facilitates efficient data exchange with the host board. The board’s two EPROM cartridges store programming data, and an attachable 16-key programmer enables on-site configuration and diagnostics.

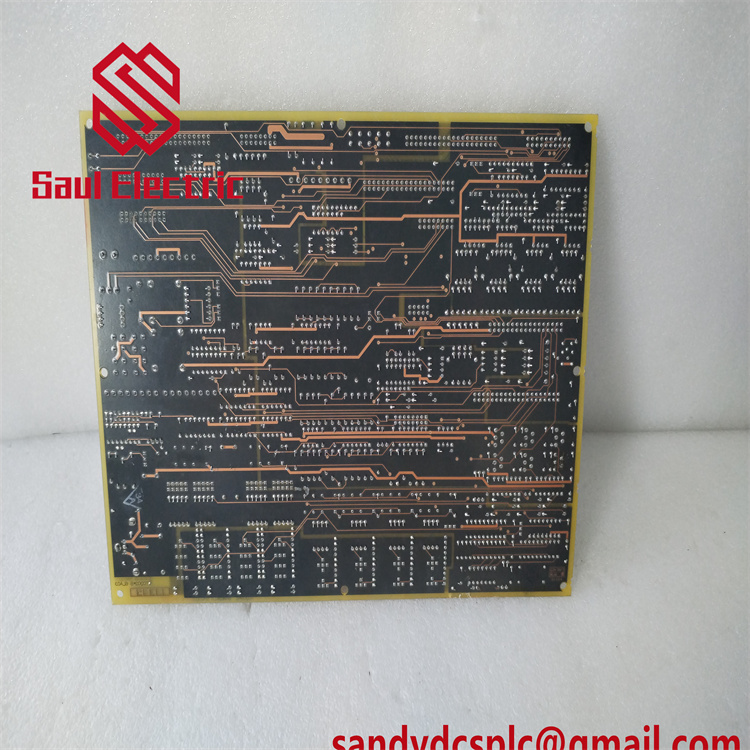

Built for rugged environments, the GE DS200SLCCG3AFG features a conformal-coated PCB to resist moisture, dust, and EMI. Its hot-swap capability minimizes downtime by allowing replacement without powering down the system. With dual isolated/non-isolated circuits, it adapts to diverse field devices, making it ideal for turbine halls, offshore platforms, and harsh industrial settings.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200SLCCG3AFG |

| Manufacturer | General Electric (GE) |

| Product Type | LAN Communication Board (Mark V Series) |

| Communication Protocols | ARCNET LAN, DLAN |

| Connectors | 3PL (data bus), 8PL (auxiliary signals), 19PL (generator voltage inputs) |

| Memory | Dual-port RAM, 2x EPROM cartridges |

| Operating Temperature | -20°C to +70°C |

| Isolation Voltage | 250 V (continuous) |

| PCB Coating | Standard conformal coating |

| Dimensions (L×W×H) | 275 mm × 225 mm × 28 mm |

| Weight | 0.52 kg |

| Compatibility | GE Mark V modules (e.g., DS200TCCAG1B, DS200TCEAG1B) |

| Functional Revisions | Primary: A, Secondary: F, Artwork: G |

Main Features and Advantages

Robust Communication: The GE DS200SLCCG3AFG ensures reliable data transmission via ARCNET LAN and DLAN, enabling real-time coordination between the Mark V controller and I/O modules. Its isolated circuits prevent ground loops, while the LCP optimizes signal processing for time-critical tasks like turbine speed regulation.

Modular Flexibility: With 3PL data bus and 19PL connectors, the board integrates seamlessly with complementary modules such as DS200TCQAG1A (analog input) and DS200TCTGG1A (generator control). Its EPROM-based programming allows field updates, adapting to evolving system requirements without hardware replacement.

Rugged Reliability: The GE DS200SLCCG3AFG’s conformal coating and vibration-resistant design ensure stability in extreme conditions (-20°C to +70°C). Hot-swap capability reduces downtime during maintenance, critical for 24/7 operations in power plants and refineries.

Simplified Diagnostics: On-board LEDs and test points enable quick fault identification, while the 16-key programmer provides direct access to settings, reducing troubleshooting time. This enhances predictive maintenance, minimizing unplanned shutdowns.

Application Areas

Turbine Control Systems: The GE DS200SLCCG3AFG manages data flow between the Mark V controller and sensors/actuators in gas/steam turbines. It processes shaft speed pulses for precise regulation, coordinates fuel valve controls via 4-20 mA signals, and supports overspeed trip interlocks with safety modules.

Power Generation: In power plants, the board facilitates grid synchronization by exchanging generator voltage data with TBQB breaker modules. Its ARCNET LAN connectivity integrates with SCADA systems for centralized monitoring of turbine performance.

Process Automation: In refineries and chemical plants, the GE DS200SLCCG3AFG interfaces with PTBA terminal boards to monitor pressure/flow, enabling distributed control of pumps and compressors. Remote diagnostics via RS232 reduce on-site visits, cutting operational costs.

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation preparation: Before installing the GE DS200SLCCG3AFG, power down the Mark V system and verify proper grounding. Use anti-static tools to avoid ESD damage. Mount the board in the R5 chassis via DIN rail or panel mounts, securing connectors to torque specs (refer to GE manual). Confirm compatibility with existing modules like DS200TCCAG1B to ensure seamless integration.

Maintenance recommendations: Inspect the GE DS200SLCCG3AFG quarterly for dust/corrosion; clean with compressed air (low pressure). Check connectors for tightness to prevent signal loss. Calibrate via GE Proficy software annually. Store spare units in a temperature-controlled environment. Replace faulty boards using hot-swap to minimize downtime, transferring EPROMs from the old unit to retain configurations.

Product Guarantee

GE backs the GE DS200SLCCG3AFG with a 1-year warranty covering material/workmanship defects. All units undergo rigorous testing for EMI, vibration, and temperature tolerance. Technical support is available 24/7 for configuration/troubleshooting. For urgent needs, the board is in stock with 3-day delivery post-payment, ensuring minimal operational disruption.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com