Description

Product Overview

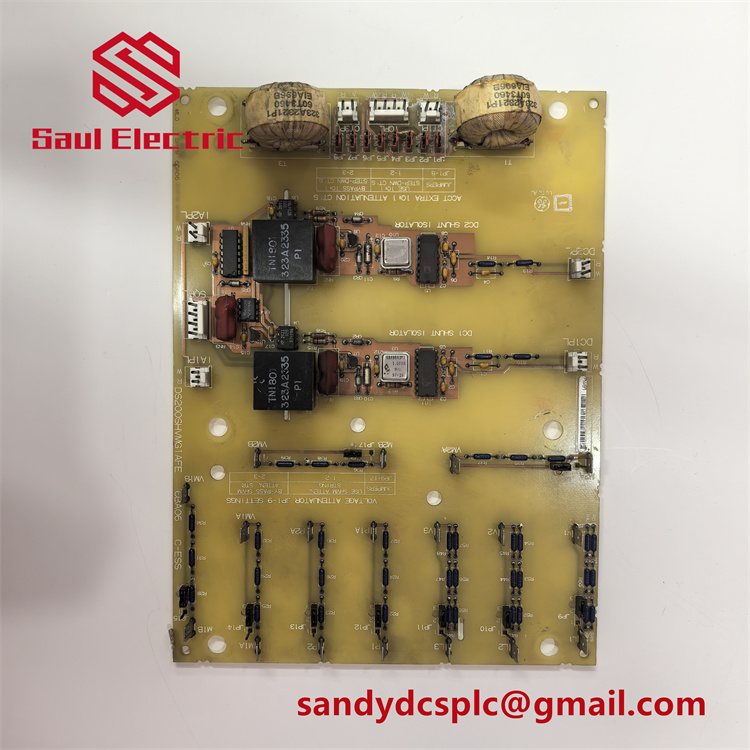

The GE DS200SLCCG1ABB is a LAN Communication Board designed for GE’s Mark V series of industrial control systems, specializing in turbine protection and safety-critical applications. As a core component of the Speedtronic LST TMR (Triple Modular Redundancy) architecture, this board manages emergency trip circuits and auxiliary control functions in power generation, oil & gas, and heavy machinery industries.

Integrated into the Mark V system’s protection core, the GE DS200SLCCG1ABB supports ARCNET LAN and DLAN (Distributed LAN) protocols for real-time data exchange between the controller and peripheral I/O modules. Its three emergency trip relays (ETR) and four auxiliary control outputs (e.g., solenoid valves for mechanical lockout and oil testing) ensure fail-safe operation in turbine systems. The board’s LAN Control Processor (LCP) filters and processes signals, while dual-port RAM and two EPROM cartridges facilitate efficient data handling and firmware updates.

Built for rugged environments, the GE DS200SLCCG1ABB features a conformal-coated PCB to resist moisture, dust, and electromagnetic interference (EMI). Its hot-swap capability minimizes downtime by allowing faulty units to be replaced without powering down the entire system. With dual isolated and non-isolated communication circuits, the board adapts to diverse field device requirements, making it ideal for turbine halls, offshore platforms, and other harsh industrial settings.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200SLCCG1ABB |

| Manufacturer | General Electric (GE) |

| Product Type | LAN Communication Board (Mark V Series, LST TMR Configuration) |

| Communication Protocols | ARCNET LAN, DLAN |

| Connectors | 3PL (data bus), 8PL (auxiliary signals), 19PL (generator voltage inputs) |

| Memory | Dual-port RAM, 2x EPROM cartridges |

| Operating Temperature | -20°C to +70°C |

| Isolation Voltage | 250 V (continuous) |

| PCB Coating | Standard conformal coating |

| Physical Dimensions | 275 mm × 225 mm × 28 mm |

| Weight | 0.52 kg |

| Compatibility | GE Mark V modules (e.g., DS200TCCAG1B, DS200TCEAG1B, IMCP, DCI) |

| Functional Revisions | Primary: A, Secondary: B, Artwork: B |

| Hot-Swap Capability | Yes |

| Emergency Trip Relays | 3x ETR (Emergency Trip Relays) |

| Auxiliary Control Outputs | 4x solenoid valve drivers (electrical lockout, oil reset, mechanical lockout, oil test) |

Main Features and Advantages

Safety-Critical Redundancy: The GE DS200SLCCG1ABB is a cornerstone of the Mark V LST TMR system, providing triple-modular redundancy to ensure fail-safe operation in turbine control. Its three emergency trip relays (ETR) monitor critical parameters (e.g., overspeed, vibration) and trigger turbine shutdowns if faults are detected, preventing catastrophic equipment damage.

Dual Communication Architecture: Supporting ARCNET LAN and DLAN, the board enables high-speed data transmission between the Mark V controller and I/O modules like DS200TCQAG1A (quad analog input) and DS200TCTGG1A (generator control). Its isolated and non-isolated circuits accommodate both low-voltage sensor signals and high-power control outputs, ensuring signal integrity in noisy environments.

Ruggedized Design: The conformal-coated PCB and IP67-rated dust/moisture resistance ensure stable performance in extreme conditions (-20°C to +70°C). The board’s vibration-resistant construction and 250 V isolation voltage make it suitable for turbine systems subject to high mechanical stress and electrical noise.

Advanced Diagnostics: The 16-key alphanumeric programmer provides direct access to fault codes and system settings, while on-board LEDs and test points enable quick troubleshooting. This enhances predictive maintenance capabilities, reducing unplanned downtime and extending equipment lifespan.

Modular Flexibility: With 3PL data bus and 19PL connector interfaces, the board integrates seamlessly with other Mark V components like DS200CTBA (high-density terminal board) and DS200SBCAG1A (next-gen Ethernet communication board). Its hot-swap capability and EPROM-based programming simplify field upgrades and reduce maintenance complexity.

Application Areas

Turbine Protection Systems: The GE DS200SLCCG1ABB is critical for overspeed protection in gas and steam turbines, monitoring shaft speed via pulse rate inputs and coordinating emergency trips with modules like DS200TCQAG1A. It also manages synchronization checks between generator and grid voltages to prevent equipment damage during load changes.

Process Automation: In refineries and chemical plants, the board interfaces with PTBA terminal boards to monitor pressure, flow, and temperature. Its DLAN support enables distributed control across multiple units, while remote diagnostics via RS232 reduce manual intervention and improve operational efficiency. For example, it can integrate with DS200TCCAG1B modules to regulate pump speeds based on real-time process data.

Power Generation: In power plants, the GE DS200SLCCG1ABB facilitates real-time data exchange between the Mark V controller and DS200TCTGG1A (generator control board), ensuring reliable grid synchronization and generator protection. Its ARCNET LAN connectivity also supports integration with supervisory control systems for centralized monitoring of turbine performance and energy output.

Safety-Critical Industries: Ideal for nuclear power plants and offshore platforms, the board’s TMR architecture and emergency trip capabilities meet stringent safety standards. It interfaces with IMCP (Interface Module Control Processor) and DCI (Drive Control Interface) boards to implement redundant control logic, ensuring continuous operation even in single-fault scenarios.

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation Preparation: Before installing the GE DS200SLCCG1ABB, ensure the Mark V system is powered down and grounded. Use anti-static wrist straps to prevent ESD damage, and verify compatibility with existing modules (e.g., DS200TCCAG1B). Mount the board in the R5 core chassis using DIN rail or panel mounts, securing connectors with torque-controlled tools. Confirm proper alignment of the 3PL data bus connector to avoid signal loss.

Maintenance Recommendations: Regularly inspect connectors for corrosion and clean the PCB with compressed air (avoiding direct airflow on components). Use GE’s Proficy software to recalibrate signal conditioning parameters annually and update firmware during system downtime. Replace faulty units immediately to maintain system integrity, leveraging the hot-swap capability for seamless replacement. For TMR configurations, perform relay testing and redundancy checks quarterly to ensure all three ETRs are operational.

Product Guarantee

GE offers a 1-year warranty for the GE DS200SLCCG1ABB, covering defects in materials and workmanship. Units undergo rigorous testing for vibration, temperature, and EMI compliance. For urgent needs, the board is available from stock with 3–5 day delivery post-payment, supported by 24/7 technical assistance for configuration and troubleshooting.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com