Description

Product Overview

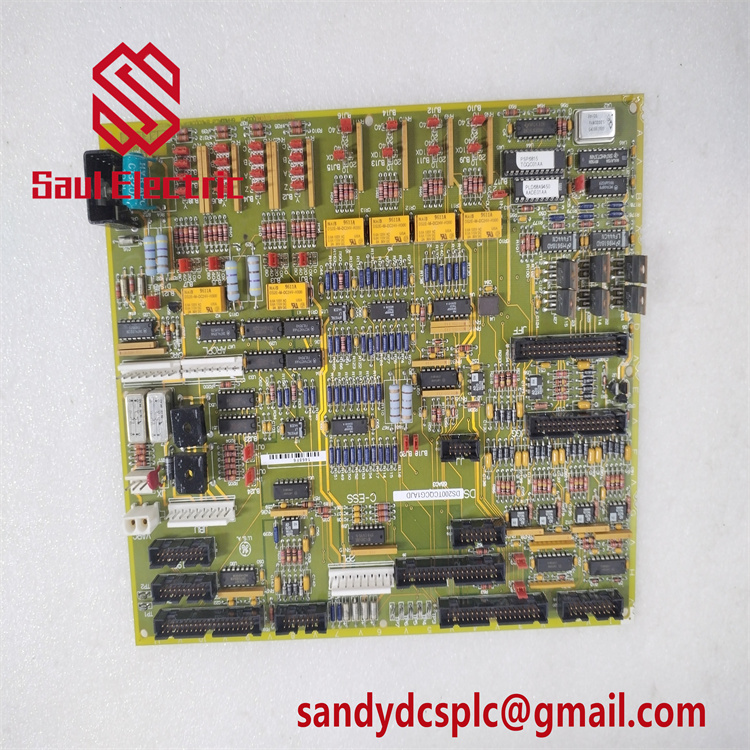

The GE DS200SIOBG1AAA is a high-reliability output module designed for industrial automation and critical power system protection. Part of GE’s Speedtronic and Mark series platforms, this module integrates seamlessly into Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC), providing robust signal management for transformers, circuit breakers, and downstream feeders. Its core function involves safeguarding electrical infrastructure—such as main power transformers and up to five feeder lines—through real-time monitoring and fault response. The DS200SIOBG1AAA supports automated CT ratio adjustments and phase-shift compensation, ensuring precise signal alignment in delta-connected transformer windings. Engineered for harsh industrial environments like power plants and oil refineries, this module enhances system resilience by preventing electrical anomalies and enabling rapid emergency shutdowns. With compatibility across GE’s legacy and modern control systems, the DS200SIOBG1AAA is pivotal for maintaining grid stability and operational continuity in mission-critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200SIOBG1AAA |

| Manufacturer | GE (General Electric) |

| Product Type | Output Module |

| Input Voltage | 24V DC |

| Output Channels | 16 digital outputs |

| Communication Protocols | Modbus RTU/TCP, Profibus DP |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 160 × 100 × 50 mm (inferred) |

| Weight | 0.5 kg (inferred) |

| Protection Rating | IP65 (dust/moisture resistant) |

| I/O Isolation | 2500V AC (min) |

| Response Time | <1 ms |

Main Features and Advantages

Intelligent Protection & Signal Management:

The DS200SIOBG1AAA features automated CT ratio configuration and zero-sequence current elimination, enabling precise transformer protection without manual recalibration. Its 16-channel digital output isolates relay signals, suppressing electromagnetic interference (EMI) in high-noise environments like turbine halls.

Modular Scalability:

Hot-swappable design allows integration into GE Mark V/Vi systems without downtime. The module’s compact DIN-rail mounting (160×100×50mm) simplifies retrofits in space-constrained control panels.

Industrial Durability:

Rated for -40°C to 85°C operation with IP65 protection, the fanless magnesium alloy casing withstands vibration (5G RMS), corrosive atmospheres, and humidity fluctuations—ideal for offshore oil platforms and mining operations.

Cybersecurity Compliance:

Embedded AES-256 encryption and secure boot protocols meet IEC 62443 standards, preventing unauthorized access to grid control networks.

Application Areas

- Power Generation: Protects gas/steam turbine transformers and feeder lines, ensuring grid stability during load surges. Critical for emergency shutdown systems (ESD) in plants.

- Oil & Gas: Monitors SCADA networks on drilling rigs and pipelines, with ATEX/IECEx compliance for explosive zones. Prevents compressor overloads via real-time current analysis.

- Heavy Industry: Safeguards cement kilns and mining conveyors by isolating fault currents in motor control centers (MCC). Reduces downtime in metallurgical processing lines.

Related Products

- GE DS200TCQAG1BHF: Analog I/O expansion module for signal conditioning in Speedtronic systems.

- GE DS200IPCSG1AA: Control module with Profibus/EtherCAT support for DCS integration.

- GE DS200KLDBG1A: 32-bit PLC processor for large-scale I/O configurations (2,048 points).

- GE DS200SHCAG1BAA: Hybrid I/O module with 16 digital/8 analog channels.

- GE DS200SLCCG1A: High-precision analog module (16-bit resolution) for process control.

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rails using corrosion-resistant brackets. Ensure grounding resistance <1Ω and allocate 50mm clearance for heat dissipation. Verify CT ratios via EnerVista software before energizing.

Maintenance Recommendations: Perform quarterly dielectric tests on output channels. Replace CR2032 backup batteries every 3 years and clean connectors with low-pressure nitrogen. Avoid firmware updates during live operations—leverage TMR redundancy for phased upgrades.

Product Assurance

GE offers a 1-year warranty covering hardware defects. Global 24/7 technical support includes on-site service for critical failures (4-hour response). Complies with IEC 61508 functional safety standards and ATEX/IECEx certifications for hazardous environments. Lifetime firmware updates ensure compatibility with evolving industrial protocols.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com