Description

GE DS200PTCTG1B Product Description

Product Overview

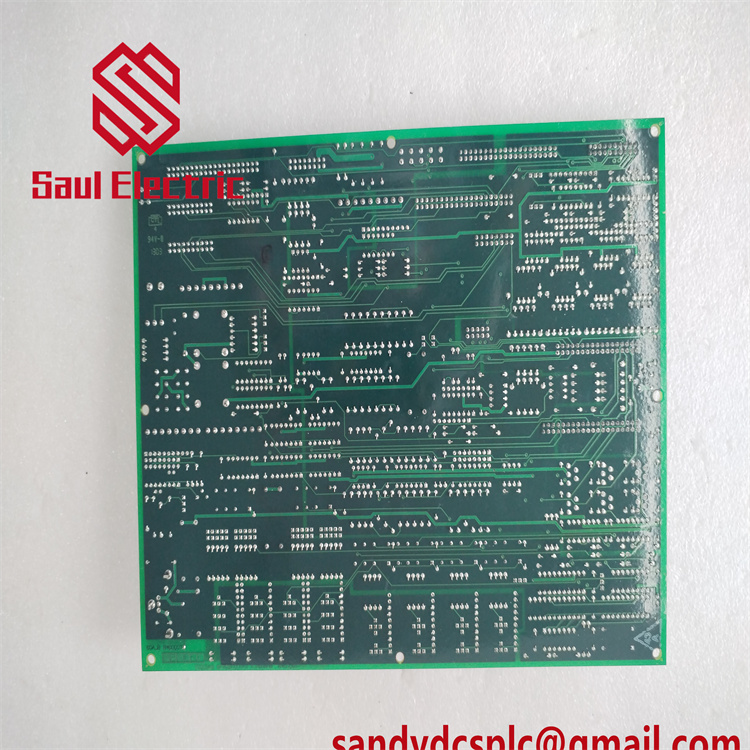

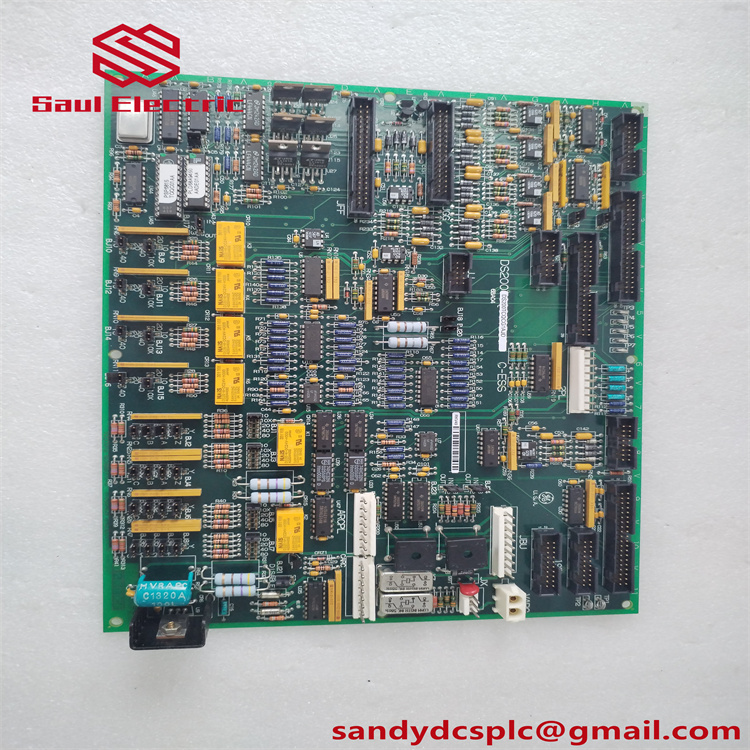

The GE DS200PTCTG1B is a Potential and Current Transformer (PT/CT) Signal Conditioner Board designed for GE’s Mark V series of industrial control systems, specializing in turbine control, power generation, and heavy machinery applications. This high-performance board interfaces with voltage (PT) and current (CT) signals from transformers, providing isolation, scaling, and conditioning for critical control loops in safety-critical environments like power plants, refineries, and renewable energy installations .

As part of the Speedtronic EX2000 platform, the GE DS200PTCTG1B processes three-phase PT/CT inputs to enable precise grid synchronization, overcurrent protection, and generator excitation control. Its 12-bit analog-to-digital conversion ensures accurate signal feedback for turbine speed regulation and power system stabilizer (PSS) integration, making it essential for maintaining grid stability in both conventional and renewable energy systems . The board’s modular design supports seamless integration with other Mark V modules, such as the TCCB Transducer Board, which converts isolated signals into digital counts for the control processor .

With surge protection on every channel and a rugged PCB design, the GE DS200PTCTG1B withstands extreme temperatures (0°C to +50°C) and electromagnetic interference (EMI), ensuring reliable operation in harsh industrial environments. Its hot-swap capability minimizes downtime during maintenance, while remote diagnostics via RS232 enable predictive maintenance and reduce manual intervention .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200PTCTG1B |

| Manufacturer | General Electric (GE) |

| Product Type | PT/CT Signal Conditioner Board (Mark V Series, EX2000 Configuration) |

| Signal Configuration | 2x Three-Phase CT Inputs, 1x Three-Phase PT Input, 4-20 mA/Low Voltage Auxiliary I/O |

| Input Range | CT: 5 A secondary (software-adjustable to 3 A), PT: 120 V AC |

| Resolution | 12 Bits (Analog-to-Digital Conversion via Voltage-Controlled Oscillators) |

| Connectors | 1x 50-Pin Connector, 1x Terminal Block (72 Signal Wires), JKK Ribbon Connector |

| Surge Protection | Metal oxide varistors (MOVs) per channel |

| Operating Temperature | 0°C to +50°C |

| Compatibility | GE Mark V modules (e.g., DS200PTCTG2B, DS200QTAG2A, TCCB Transducer Board) |

| Hot-Swap Capability | Yes |

| Physical Dimensions | 25.9 x 16.0 x 6.4 cm (10.2 x 6.3 x 2.5 inches) |

| Weight | 1.6 kg (3.5 lbs) |

| Warranty | 1 Year (GE OEM), 24 Months (Refurbished Units) |

Key Features and Advantages

Precision Signal Conditioning: The GE DS200PTCTG1B processes PT/CT signals with ±0.1% accuracy, ensuring reliable measurement of generator stator current and bus voltage for grid synchronization and overcurrent protection. Its software-adjustable CT input range (3–5 A) accommodates diverse generator configurations .

Rugged Design for Harsh Environments: Built with industrial-grade components and conformal coating, the board resists vibration, humidity, and EMI. Metal oxide varistors (MOVs) on each channel protect against voltage surges, while the operating temperature range of 0°C to +50°C suits extreme industrial settings .

Seamless Integration: The board interfaces with the TCCB Transducer Board via a JKK ribbon connector, converting isolated PT/CT signals into digital counts for the Mark V controller. It also supports auxiliary 4-20 mA and low-voltage inputs/outputs for integrating external sensors and actuators .

Minimized Downtime: Hot-swap capability allows replacement of faulty boards without powering down the system, reducing maintenance time. Remote diagnostics via RS232 enable real-time monitoring of signal integrity and firmware updates, optimizing operational efficiency .

Application Areas

Power Generation: The GE DS200PTCTG1B plays a critical role in thermal and renewable power plants by processing PT/CT signals for generator excitation control and power system stabilizer (PSS) integration. It ensures accurate synchronization with the grid, preventing voltage instability and equipment damage .

Turbine Control Systems: In gas and steam turbines, the board interfaces with CTs to monitor stator current and PTs to measure bus voltage, enabling precise speed regulation and overcurrent protection. Its compatibility with the Speedtronic EX2000 platform makes it ideal for modernizing legacy turbine control systems .

Heavy Industry: Used in refineries and chemical plants, the GE DS200PTCTG1B supports high-voltage process valve control by conditioning signals from PTs/CTs. Its auxiliary I/O channels facilitate integration with motor protection contactors and distributed control systems (DCS) .

Renewable Energy: In wind turbines, the board processes PT/CT signals for grid synchronization and power quality management. Its software-adjustable CT inputs accommodate variable generator outputs, ensuring stable operation in dynamic wind conditions .

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation Preparation: Mount the GE DS200PTCTG1B in the R5 core chassis using DIN rail or panel mounts. Secure connectors with torque-controlled tools and verify jumper settings for PT/CT signal type (5 A CT or 120 V PT). Use shielded cables and route signal wires away from high-voltage power cables to minimize EMI .

Maintenance Recommendations: Regularly inspect connectors for corrosion and clean the PCB with compressed air. Use GE’s Proficy software to monitor signal status and update firmware during scheduled downtime. Replace aging components preemptively, leveraging the board’s hot-swap capability for seamless replacement. For triple modular redundant (TMR) systems, perform quarterly redundancy tests to ensure fail-safe operation .

Product Guarantee

GE provides a 1-year warranty for new GE DS200PTCTG1B units, covering defects in materials and workmanship. Refurbished units come with a 24-month warranty, including component replacement and functional verification. All boards undergo rigorous testing for vibration, temperature, and EMI compliance. With 3–5 day delivery post-payment and 24/7 technical support, GE ensures rapid deployment and reliable operation. For modernization, consider upgrading to the GE DS200SBCAG1A for enhanced connectivity and processing power .

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com