Description

Product Overview

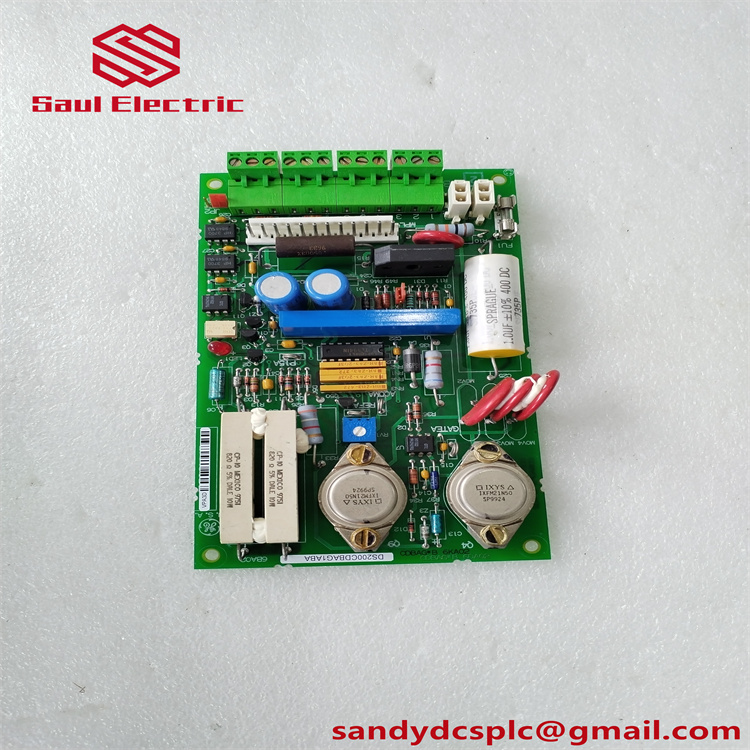

The GE DS200CDBAG1ABA is a contactor driver board designed for GE’s Mark V series turbine control systems, serving as a critical component in industrial automation and power generation applications. Engineered to interface between drive controls and high-speed contactors, this module enables precise activation/deactivation of contactors while providing fast dropout protection in AC/DC 2000 drive systems. As part of the Mark V platform, the DS200CDBAG1ABA integrates advanced circuit design with configurable features to meet demanding operational requirements in hazardous and non-hazardous environments.

The board supports 75–140V AC/DC input voltage and includes three test points for real-time monitoring of voltage references (REF A, +15V DC, and board common). A factory-calibrated potentiometer (RV1) adjusts contactor coil current, while a 4A slow-blow fuse (FU1) protects against overcurrent. Its hot-swap capability allows maintenance without system shutdown, minimizing downtime in power plants and industrial facilities. The DS200CDBAG1ABA features a single 3-pin jumper (JP1) for factory testing and is compatible with GE’s DS200DCFBG1BLC power supply board and DS200SDCI instrumentation board39.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS200CDBAG1ABA |

| Manufacturer | GE (General Electric) |

| Product Type | Contactor Driver Board for Mark V Turbine Control Systems |

| Input Voltage | 75–140V AC/DC (50/60Hz) |

| Output Signal | Contactor control voltage (30–40V DC typical) |

| Configuration | 1x 3-pin jumper (JP1, factory-set), 1x potentiometer (RV1) |

| Diagnostic Indicators | 1x LED (status/fault), 3x test points (REF A, +15V DC, common) |

| Test Points | TP1 (board common), TP2 (+15V DC), TP3 (REF A voltage) |

| Fuse Protection | 4A slow-blow fuse (FU1) |

| Operating Temperature | -40°C to +70°C (non-condensing) |

| Dimensions | 120mm (W) × 80mm (H) × 50mm (D) |

| Weight | 0.38 kg |

| Certifications | CE, UL 508, CSA C22.2 No. 14 |

| Compatibility | GE Mark V drives (AC2000, DC2000, CB2000, ME2000, FC2000, EX2000) |

| Instruction Manual | GEI-100182B (Contactor Driver Board Manual) |

Main Features and Advantages

The GE DS200CDBAG1ABA excels in mission-critical contactor control, providing galvanic isolation between drive controls and high-power contactors. Its fast dropout protection ensures rapid disconnection in fault conditions, safeguarding equipment from damage. The board’s modular design supports seamless integration with GE’s Mark V control systems, simplifying retrofits and expansions. Key advantages include:

- Precision Current Control: Factory-calibrated potentiometer (RV1) ensures stable contactor coil current, preventing arcing and wear.

- Rugged Construction: Conformal coating and EMI/RFI shielding protect against harsh environments, including offshore platforms and high-vibration settings918.

- Proactive Diagnostics: Test points enable quick verification of voltage references, while the LED indicator alerts users to faults (e.g., open circuits, overcurrent).

- Coordinated Operation: Optional jumper (JP2) allows multi-bridge synchronization for simultaneous contactor control in complex systems9.

Application Areas

The GE DS200CDBAG1ABA is widely deployed in industries requiring reliable contactor management:

- Power Generation: Controls steam/gas turbine exciters, generator breakers, and motor starters in utility-scale power plants.

- Oil & Gas: Manages compressor drives, pump systems, and wellhead equipment in offshore platforms and refineries.

- Industrial Automation: Powers robotic assembly lines, conveyor systems, and process control drives in manufacturing facilities.

- Water/Wastewater Treatment: Integrates with pumps and filtration systems for closed-loop control in hazardous environments.

Related Products

Installation and Maintenance

Installation Preparation:

- Mount the GE DS200CDBAG1ABA in a Mark V rack, securing it with captive screws.

- Connect 75–140V AC/DC input to terminals J1/J2 and ground the board per GEI-100182B guidelines.

- Verify shielded cabling to minimize EMI and ensure contactor coil voltage matches the board’s 30–40V DC output.

- Configure JP1 jumper (pins 1–2 covered for normal operation) and adjust RV1 potentiometer only if factory settings require recalibration318.

Maintenance Recommendations:

- Weekly Checks: Monitor LED status and test point voltages (TP1–TP3) using a multimeter.

- Quarterly Inspections: Inspect terminal connections for corrosion or looseness, especially in high-humidity environments.

- Annual Calibration: Verify contactor coil current using test points REF A and ACOMA (refer to GEI-100182B).

- Firmware Updates: Download the latest firmware from GE’s support portal to access performance optimizations.

Product Guarantee

The GE DS200CDBAG1ABA is backed by a 12-month warranty covering manufacturing defects, with optional extended warranties (up to 3 years) available for critical applications. GE’s global technical support team provides 24/7 assistance for troubleshooting, including remote diagnostics and on-site service. Replacement units are stocked in regional warehouses for expedited delivery (2–5 days), ensuring minimal operational disruption. The module undergoes rigorous testing to meet IEC 61131-2 and IEEE standards, ensuring long-term reliability in even the most demanding industrial environments39.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com