Description

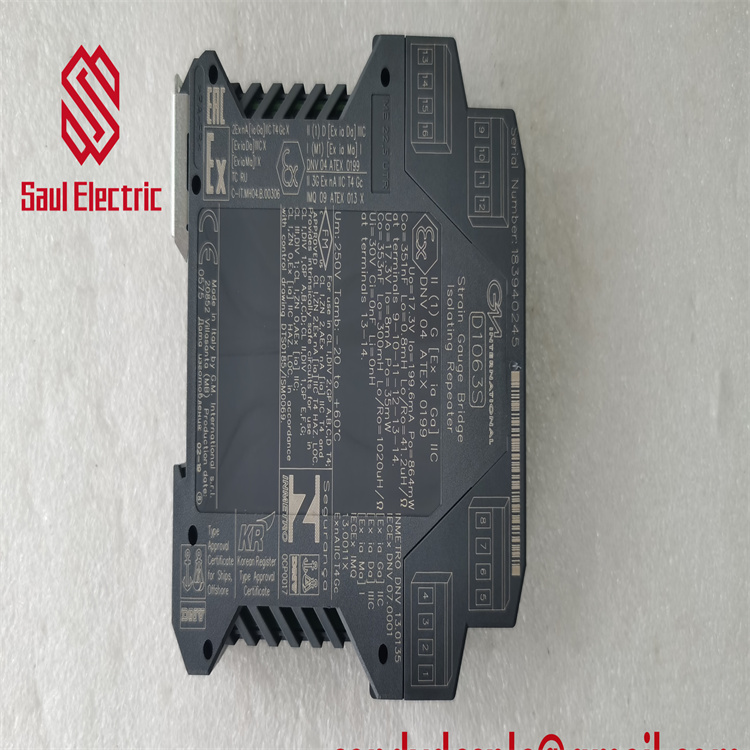

GE D1063S

Product Overview

The GE D1063S is a high-precision galvanic isolation repeater designed for hazardous industrial environments, engineered to provide reliable signal transmission between load cells/strain gauge bridges in Zone 0/Division 1 and control systems in safe areas. As a critical component for weight measurement and process control, this module ensures signal integrity while maintaining intrinsic safety compliance. The GE D1063S supports up to 4x 350Ω load cells in parallel (or equivalent configurations) and features three-port isolation (input/output/supply), protecting against ground loops and electrical noise. Its compact DIN rail-mountable design and ATEX/IECEx certification make it suitable for oil & gas, chemical, and pharmaceutical industries where explosion-proof performance is essential.

Equipped with remote sensing capability, the GE D1063S compensates for voltage drops in long cable runs, ensuring accurate mV signal transmission. The module includes built-in field wiring fault detection via a red LED indicator, enabling proactive maintenance to minimize downtime. Its dip-switch configurability allows seamless adaptation to different excitation voltages (internal or external) and signal ranges, while EMC compliance (EN 61000-6-2/-4) ensures robust performance in electromagnetic interference-prone environments. With a wide operating temperature range (-20°C to +60°C) and marine-grade certifications (DNV, KR), the GE D1063S delivers exceptional durability in harsh offshore and onshore applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE D1063S |

| Manufacturer | GE (General Electric) |

| Product Type | Galvanic Isolation Repeater for Load Cells/Strain Gauge Bridges |

| Input Signal | Strain gauge bridge (3-wire or 4-wire) |

| Output Signal | Isolated mV signal (transparent repeat) |

| Load Cell Compatibility | Up to 4x 350Ω, 6x 450Ω, or 12x 1000Ω load cells in parallel |

| Isolation Voltage | 250 Vrms (Um) |

| Power Supply | 20–30 V DC (19.2–31.2 V DC for hazardous area operation) |

| Operating Temperature | -20°C to +60°C (non-condensing) |

| Storage Temperature | -45°C to +80°C |

| Dimensions | 120mm (W) × 100mm (H) × 60mm (D) |

| Weight | 0.3 kg |

| Certifications | ATEX (II 1G Ex ia IIC T4), IECEx (Ex ia IIC T4), FM, DNV, KR, EAC |

| Fault Detection | Field wire breakage indication (LED) |

| EMC Compliance | EN 61000-6-2 (immunity), EN 61000-6-4 (emission) |

Main Features and Advantages

The GE D1063S excels in hazardous area applications, offering intrinsic safety (Ex ia IIC) for use in Zone 0/Division 1 environments. Its transparent signal repetition eliminates the need for Zener barriers, simplifying system design while maintaining galvanic isolation between hazardous and safe areas. The module’s remote sensing capability ensures accurate load cell excitation by compensating for voltage drops in long cables, critical for precise weighing systems in oil refineries and chemical plants.

Reliability is enhanced through advanced diagnostics, including real-time monitoring of field wiring integrity. The GE D1063S also supports parallel load cell configurations, allowing up to 12x 1000Ω load cells to be connected without signal degradation—a key advantage for large-scale industrial weighing systems. Its dip-switch programmability enables quick configuration of voltage reference (internal/external) and signal scaling, reducing commissioning time. The module’s rugged construction and marine certifications make it suitable for extreme environments, including offshore platforms and corrosive industrial settings.

Application Areas

The GE D1063S is widely deployed in industries requiring safe and accurate load cell signal transmission:

- Oil & Gas: Manages wellhead load monitoring, pipeline strain measurement, and offshore platform weighing systems in explosive gas/dust environments.

- Chemical & Pharmaceutical: Ensures precise material dosing and reactor weight control in Zone 0-rated production facilities.

- Food & Beverage: Supports hygienic weighing systems in hazardous areas, such as processing plants with flammable solvents.

- Mining: Monitors conveyor belt tension and ore bin weights in underground mines with methane gas risks.

- Marine: Integrates with shipboard cargo weighing systems and offshore crane load monitoring under DNV/KR certifications.

Related Products

- GE D1063: Single-channel variant without hazardous area certification, suitable for non-explosive environments.

- GE D1061: Multi-channel isolation repeater for simultaneous monitoring of up to 8 load cells.

- GE D1054: Compact version with reduced power consumption, ideal for space-constrained applications.

- GE PSD 1000: Power supply module for D1000 series repeaters, providing redundant 24V DC power.

- GE CABF012: Dedicated 3x2x1 mm² cable with screened termination for load cell connections.

- GE PPC1092: Serial adapter configurator for in-field parameter adjustments.

- GE D2000 Series: Modular isolation systems for complex hazardous area networks.

Installation and Maintenance

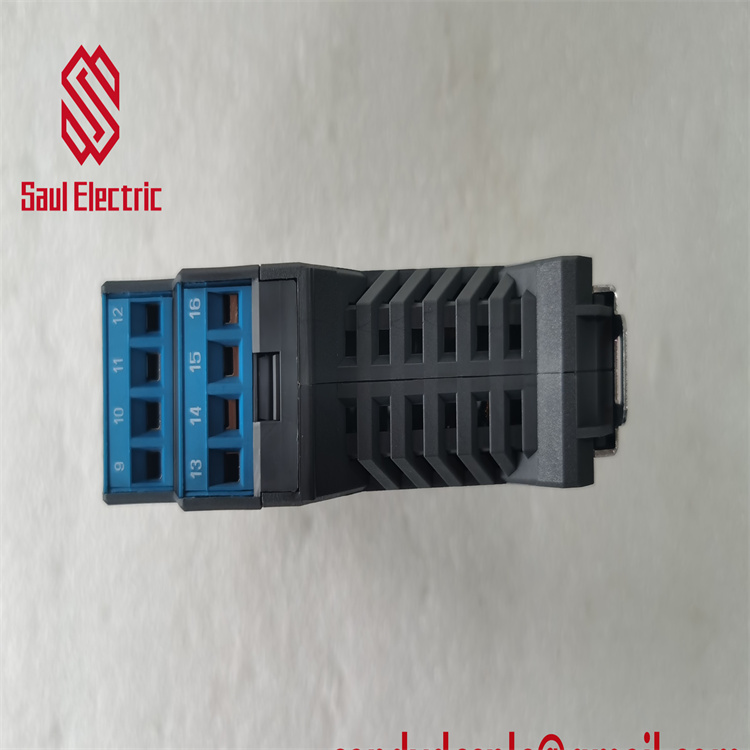

Installation Preparation: Mount the GE D1063S on a DIN rail in a safe area (Zone 2/Division 2). Connect the load cell cables to terminals 9–14 (hazardous area side) and the control system to terminals 1–8 (safe area side). Ensure proper grounding and use shielded cables to minimize EMI. Configure dip switches for voltage reference (internal/external) and load cell type via the instruction manual.

Maintenance Recommendations: Regularly inspect the module for loose connections or corrosion, especially in high-moisture environments. Monitor the fault LED—flashing indicates field wire breakage or overload. Calibrate the module annually using a certified multimeter to verify signal accuracy. Replace the module if exposed to temperatures exceeding +60°C or voltages beyond 30V DC. For ATEX-certified applications, follow IEC 60079-17 guidelines for periodic safety checks.

Product Guarantee

The GE D1063S is backed by a 2-year warranty covering manufacturing defects, with optional extended warranties available for mission-critical applications. GE’s global technical support team provides 24/7 assistance for installation, configuration, and troubleshooting, including remote diagnostics via the PPC1092 adapter. Replacement units are stocked in regional warehouses for expedited delivery (2–5 days), minimizing operational disruptions. The module undergoes rigorous testing to meet IEC 61131-2 and IEEE standards, ensuring long-term reliability in even the most demanding hazardous environments.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com