Description

GE BK698CPA15B0

Product Overview

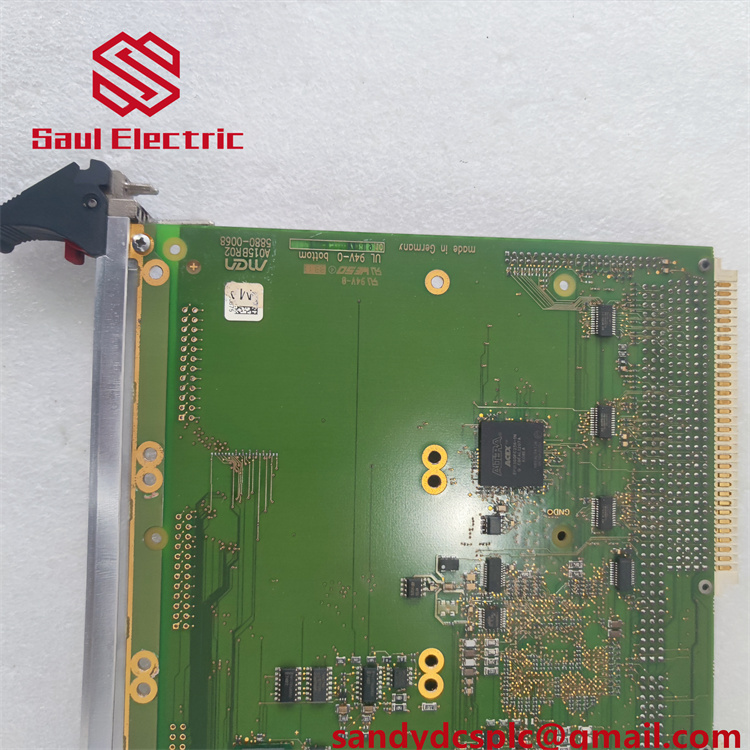

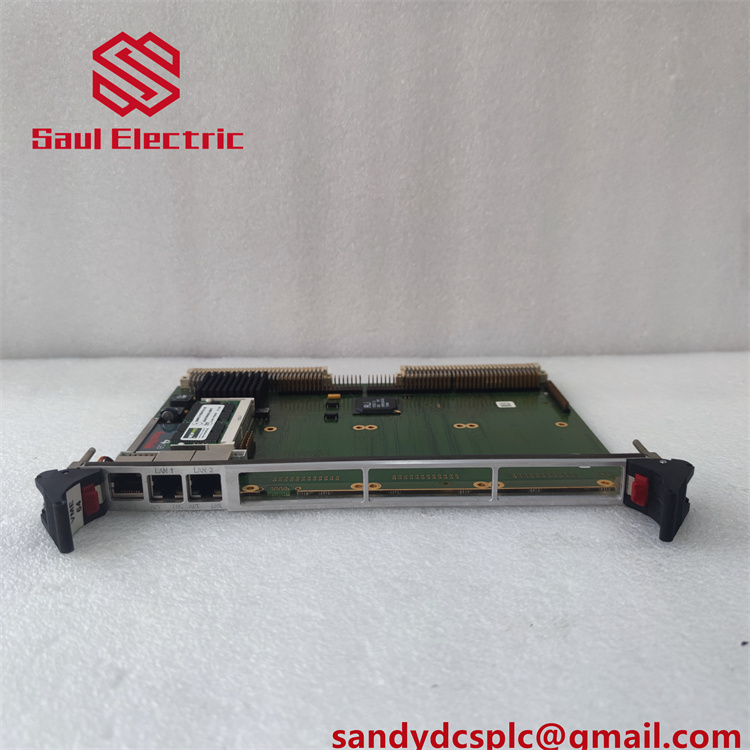

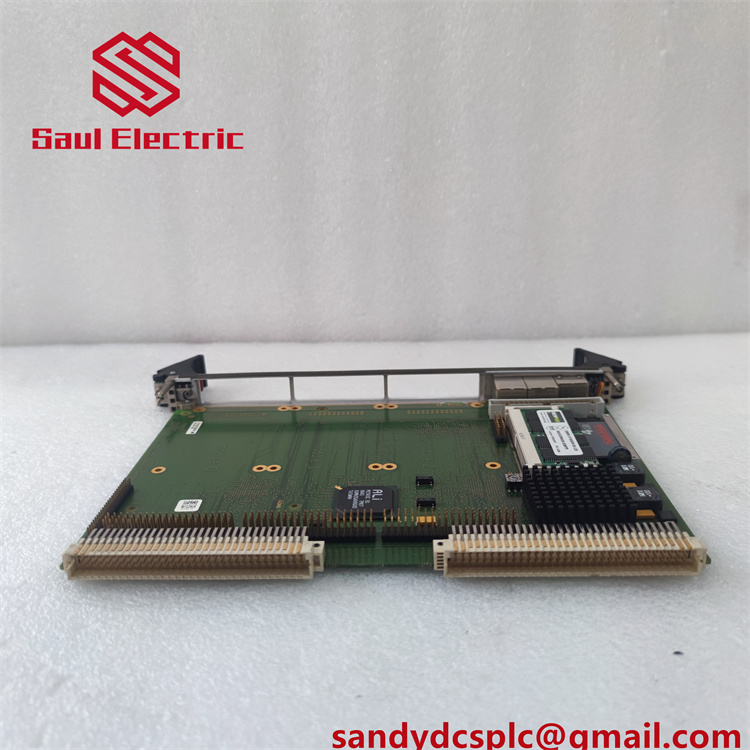

The GE BK698CPA15B0 is a high-performance industrial control processor module designed for complex automation systems, belonging to GE’s advanced RX3i PACSystems series. Engineered for mission-critical applications, this module serves as the central processing unit (CPU) in industrial control networks, delivering robust computing power and versatile connectivity. The GE BK698CPA15B0 features a 1.2GHz Intel Celeron processor, 2GB DDR3 RAM, and 16GB industrial-grade flash storage, enabling real-time control logic execution and data management in demanding environments. Its modular design supports hot-swap capability and redundant power supplies, ensuring high availability in 24/7 operations.

As a core component of the RX3i platform, the GE BK698CPA15B0 communicates via high-speed backplane interfaces and supports multiple industrial protocols (Ethernet/IP, Modbus TCP, Profibus DP), facilitating seamless integration with I/O modules, HMIs, and SCADA systems. Its rugged construction (operating temperature: -40°C to +70°C) and resistance to vibration/EMI make it suitable for harsh industrial settings, while advanced diagnostics and non-volatile memory enhance system reliability and maintenance efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE BK698CPA15B0 |

| Manufacturer | GE (General Electric) |

| Product Type | Industrial Control Processor (CPU) |

| Processor | 1.2GHz Intel Celeron J1900 (quad-core) |

| Memory | 2GB DDR3 RAM (expandable to 4GB) |

| Storage | 16GB industrial-grade flash (optional 64GB SSD) |

| Communication Interfaces | 2x Gigabit Ethernet, 1x RS-232, 1x USB 2.0 |

| Protocol Support | Ethernet/IP, Modbus TCP, Profibus DP, CANopen |

| Backplane Interface | RX3i high-speed backplane (32-bit, 66MHz) |

| Operating Temperature | -40°C to +70°C (non-condensing) |

| Power Supply | 24V DC (±10%), 5V DC (backplane) |

| Dimensions | 170mm (W) × 150mm (H) × 40mm (D) |

| Weight | 0.9 kg |

| Redundancy Support | Hot-swap, dual power inputs (optional) |

| Certifications | CE, UL 508, CSA C22.2 No. 14 |

Main Features and Advantages

The GE BK698CPA15B0 excels in high-performance processing, leveraging a quad-core Intel Celeron processor to handle complex control algorithms and real-time data analysis for up to 256 I/O modules. Its versatile communication capabilities support multiple industrial protocols, eliminating the need for separate gateway devices and simplifying system integration. The module’s hot-swap capability allows online replacement without system shutdown, a critical feature for minimizing downtime in manufacturing and energy sectors.

Industrial-grade reliability is ensured through extreme environmental tolerance, including operation in -40°C to +70°C temperatures and resistance to shock/vibration (30G peak, 11ms). The advanced diagnostic system provides real-time health monitoring via LED indicators and built-in self-test routines, enabling proactive maintenance. The module’s scalable architecture supports memory expansion and optional SSD storage for enhanced data logging, while its compatibility with GE’s Proficy Machine Edition software streamlines programming and configuration.

Application Areas

The GE BK698CPA15B0 is widely deployed in industries requiring robust control and data management:

- Manufacturing: Manages robotic assembly lines, conveyor systems, and quality control processes in automotive and food & beverage plants, ensuring precise motion control and production optimization.

- Energy & Power: Controls turbine generators, switchgear, and energy distribution systems in power plants, enabling real-time adjustment to grid demands and renewable energy integration.

- Oil & Gas: Operates upstream wellhead systems, midstream pipelines, and downstream refinery processes, withstanding harsh offshore/onshore environments while maintaining reliable data transmission.

- Water Treatment: Automates water filtration, wastewater treatment, and pump station operations, ensuring consistent flow and chemical dosing through closed-loop control.

- Aerospace & Defense: Supports test benches, robotic systems, and embedded control in aerospace manufacturing, with rugged design meeting military-grade environmental standards.

Related Products

- GE BK698CPA20B0: Higher-performance variant with 2.0GHz processor and 4GB RAM for data-intensive applications.

- GE BK698CPB15B0: Compact version with reduced I/O capacity, suitable for small-scale automation systems.

- GE AI3481: 8-channel analog input module, often paired with GE BK698CPA15B0 for process data acquisition.

- GE AO3481: 8-channel analog output module for precise control signal transmission in closed-loop systems.

- GE DI3501: Digital input module for discrete signal monitoring in industrial control networks.

- GE DO3501: Digital output module for relay/solenoid control, compatible with RX3i backplane.

- GE 8507-BI-DP: Profibus DP bus interface module for integrating legacy devices with GE BK698CPA15B0.

Installation and Maintenance

Installation Preparation: Ensure the RX3i chassis is properly grounded and powered (24V DC). Mount the GE BK698CPA15B0 in the CPU slot of the RX3i rack, securing it with captive screws. Connect Ethernet, serial, and power cables, ensuring shielded wiring to minimize EMI. Use GE’s Proficy Machine Edition software to configure network parameters, I/O mapping, and communication protocols before powering on the system.

Maintenance Recommendations: Regularly inspect the module for loose connections or overheating, especially in high-vibration environments. Monitor diagnostic LEDs for power, network, and health status—flashing indicators signal potential issues like memory errors or communication faults. Update firmware quarterly via GE’s support portal to access security patches and performance improvements. For redundant systems, test failover functionality annually by simulating a primary CPU failure to ensure seamless switching.

Product Guarantee

The GE BK698CPA15B0 is backed by a 12-month warranty covering manufacturing defects, with optional extended warranties available for critical applications. GE’s global technical support team provides 24/7 assistance for installation, programming, and troubleshooting, including remote diagnostics and on-site service. Replacement units are stocked in strategic warehouses for expedited delivery (3–5 days), minimizing operational disruptions. The module undergoes rigorous testing to meet IEC 61131-2 and IEEE standards, ensuring long-term reliability in even the most demanding industrial environments.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com