Description

Product Overview

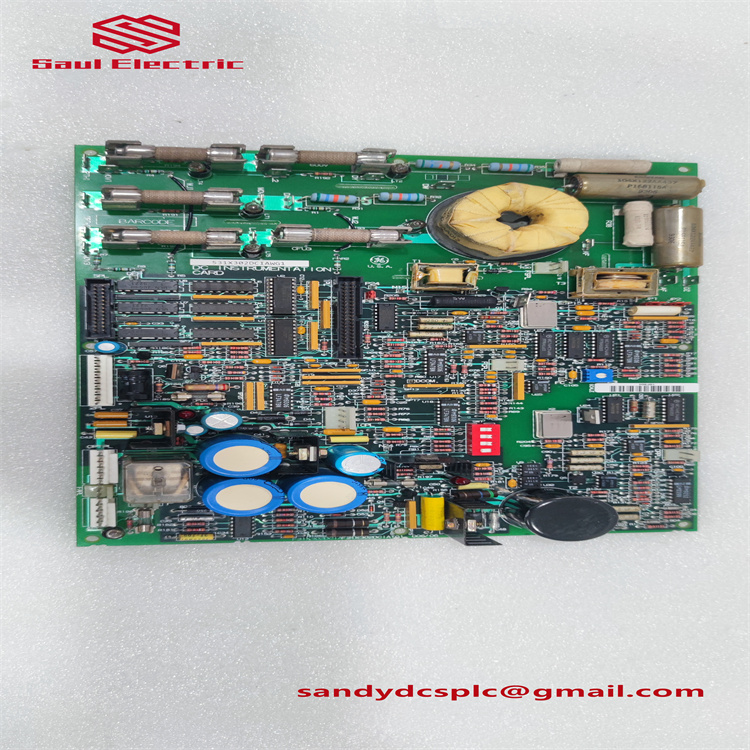

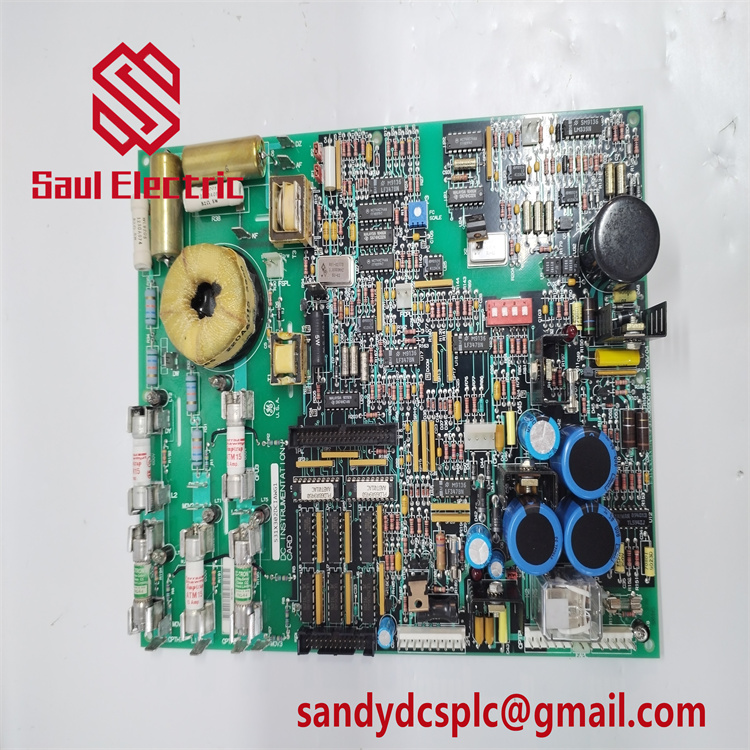

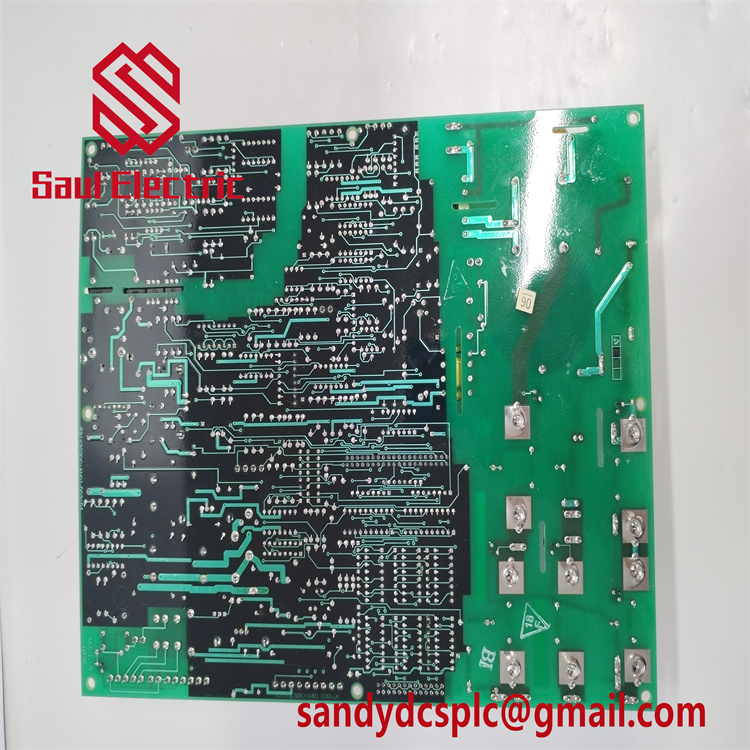

The GE 531X305NTBANG1 is a high-performance NTB/3TB terminal board designed by General Electric for industrial automation and control systems. It serves as a critical interface module for signal conditioning, power distribution, and device connectivity, integrating functionalities such as relay control, analog/digital I/O processing, and encoder interfacing. As part of GE’s 531X series, this terminal board enhances system reliability in demanding environments like power plants and manufacturing facilities. Its modular design simplifies integration with PLCs (e.g., GE RX3i), sensors, and motor drives, reducing wiring complexity while providing robust electrical isolation. The GE 531X305NTBANG1 excels in real-time data exchange and power management, making it essential for applications requiring precise control and resilience to voltage fluctuations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 531X305NTBANG1 |

| Manufacturer | GE (General Electric) |

| Product Type | NTB/3TB Terminal Board |

| Input Voltage | 24V DC |

| Regulated Output | +5V DC, +15V DC |

| Unregulated Output | 24V DC or 125V AC |

| Relay Outputs | 7 relays (Type A/C, 120V AC) |

| Analog I/O Scaling | 4 potentiometers |

| Communication Protocols | Modbus, Profibus, Ethernet, RS-232/485 |

| Operating Temperature | -20°C to +70°C (extended: -40°C to 85°C) |

| Dimensions | 531 mm × 305 mm × 65 mm |

| Weight | 1.5 kg |

| Protection Rating | IP20 (standard) |

| Certifications | CE, UL, RoHS |

Key Features and Advantages

Multifunctional Integration:

The GE 531X305NTBANG1 consolidates relay control (7×120V AC outputs), analog I/O signal processing via onboard potentiometers, and dual power supplies (regulated 5V/15V DC + unregulated 24V DC/125V AC). This eliminates the need for external signal conditioners, reducing system complexity and cost.

Industrial Resilience:

Encased in flame-retardant polycarbonate, the board operates reliably in harsh conditions (-40°C to 85°C) with EMI-resistant circuitry. Integrated diagnostics enable rapid fault detection, minimizing downtime in critical processes like turbine control or pump systems.

Communication Versatility:

Support for Modbus, Profibus, and Ethernet protocols ensures seamless integration with PLCs and SCADA systems. The isolated encoder interface (configurable to 5V/15V via jumpers) prevents signal interference in high-noise environments such as mining or oil refineries.

Applications

- Power Generation: Integrates with GE Mark VI Speedtronic systems for turbine excitation control, stabilizing voltage/frequency in power plants.

- Industrial Automation: Connects PLCs to motor drives in manufacturing lines (e.g., conveyors, crushers), enabling real-time monitoring and control.

- Water Treatment: Manages pump control and chemical dosing via analog I/O signals, ensuring precise flow regulation.

- Oil & Gas: Interfaces with drilling safety systems, utilizing relay outputs for emergency shutdowns and valve control.

- Smart Buildings: Centralizes HVAC and lighting communications through Modbus/Ethernet links.

Related Products

- 531X305NTBAPG1: Alternate variant with identical interface functions, compatible with GE EX2000 excitation systems.

- IC697MDL250: GE discrete input module for complementary digital signal handling.

- DS200TBQCG1AAA: Analog terminal board for GE Speedtronic turbine controls.

- F31X305NTBANG1: Enhanced model with expanded communication interfaces.

- +E205 EMC Filter: Optional filter to reduce electromagnetic interference in sensitive installations.

Installation and Maintenance

Installation Preparation: Verify input voltage compatibility (24V DC) before connecting the GE 531X305NTBANG1. Mount in IP20-rated enclosures with ≥50 mm clearance for ventilation. Ground all terminals to prevent electrostatic damage; use anti-static packaging during handling.

Maintenance Recommendations: Clean dust quarterly with compressed air. Inspect relay contacts annually for wear and calibrate analog I/O potentiometers every 12 months. Utilize onboard diagnostics for real-time health monitoring.

Product Assurance

GE provides a 12-month warranty covering defects in materials and workmanship. Global technical support includes lifecycle maintenance guidance and expedited replacement for critical failures. All units undergo IEC/UL compliance testing for operational reliability.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com