Description

Product Overview

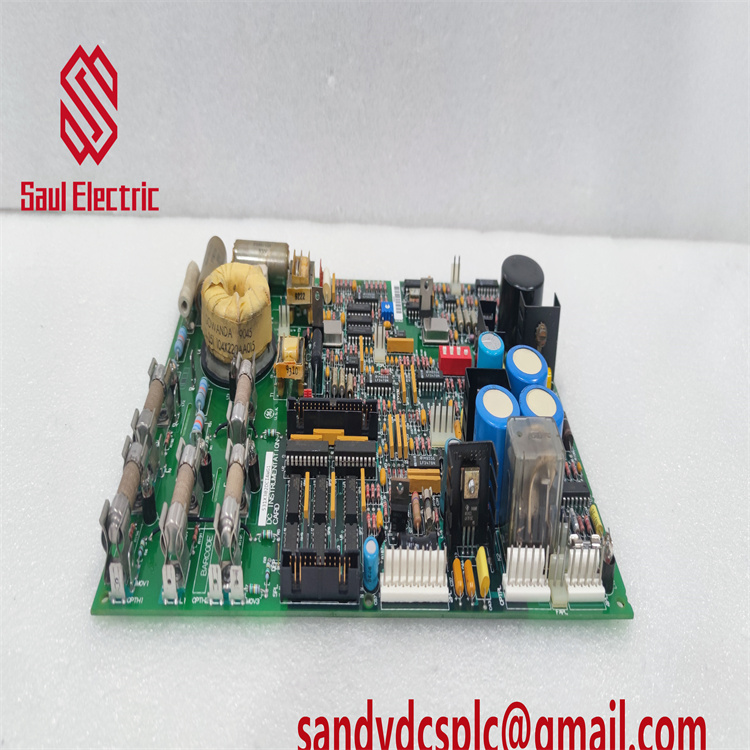

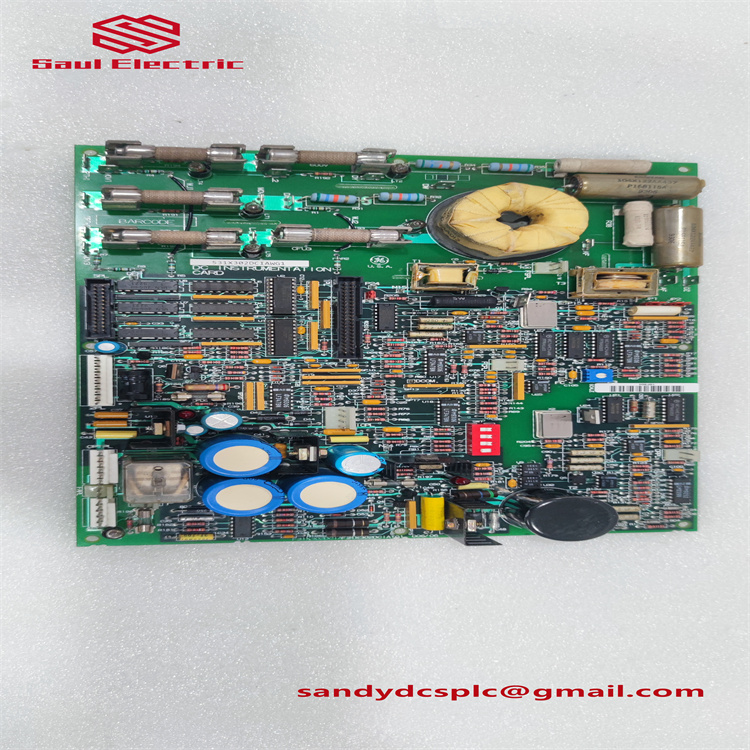

The GE 531X301DCCAGG2 is a high-performance variable frequency drive (VFD) engineered by GE Digital for precise control of AC induction motors in industrial automation systems. As part of GE’s 531X series, this drive integrates advanced torque control algorithms and modular power electronics to optimize motor efficiency across diverse applications. Designed for robustness, it supports dynamic load adjustments with a frequency range of 0.5–200 Hz, enabling energy savings up to 30% in pump, fan, and conveyor systems. The 531X301DCCAGG2 leverages GE’s proprietary control technology to ensure stable operation under voltage fluctuations and harsh environments (-20°C to +60°C), making it ideal for continuous process industries such as water treatment and manufacturing .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 531X301DCCAGG2 |

| Manufacturer | GE (General Electric) |

| Product Type | Variable Frequency Drive (VFD) |

| Input Voltage | 380–480 V AC ±15% |

| Output Power Range | 5.5–75 kW (modular) |

| Output Frequency | 0.5–200 Hz |

| Overload Capacity | 150% for 60 seconds |

| Efficiency | >95% |

| Communication Protocols | Modbus RTU, CAN, RS485, Ethernet |

| Protection Class | IP20 (standard); IP55 (optional) |

| Dimensions | 200 × 150 × 80 mm (estimated) |

| Weight | ~2.5 kg |

Key Features and Advantages

Dynamic Control Precision:

Utilizing Direct Torque Control (DTC) technology, the GE 531X301DCCAGG2 achieves ±0.2% speed accuracy without encoder feedback, critical for synchronous conveyor systems and precision machining. Its adaptive algorithms compensate for load inertia changes, preventing motor stalling in high-torque scenarios .

Energy Optimization:

Integrated power factor correction (PFC) reduces grid harmonics by 40%, while auto-tuning functions dynamically adjust voltage-to-frequency ratios, cutting energy consumption by 10–30% in HVAC and pumping applications .

Resilience & Diagnostics:

Encased in corrosion-resistant alloy, the drive withstands dust and humidity (IP55 option). Built-in diagnostics monitor thermal overloads, DC-link health, and IGBT status, triggering pre-emptive alerts via Ethernet to minimize downtime .

Applications

- Water Treatment: Controls pump arrays for precise flow regulation, reducing pipe stress and energy waste in filtration systems.

- Manufacturing: Drives CNC spindles and assembly line conveyors with synchronized speed profiles.

- HVAC Systems: Manages fan motors in commercial buildings, adapting to seasonal load variations.

- Renewable Energy: Integrates with wind turbine pitch control systems (complementary to GE 2.X platforms) .

Related Products

- 531X301DCCAFG2: Base model with identical control logic, limited to 55 kW .

- IC697MDL250: GE I/O module for expanding digital signal interfaces.

- DSTD150A 57160001-UH: Connection unit for cascading multiple drives.

- UDD406A 3BHE041464R0101: Digital input module for safety interlocks .

Installation and Maintenance

Installation Preparation: Verify input voltage compatibility (380–480V) before wiring. Mount on DIN rail with ≥50 mm lateral clearance for heat dissipation. Ground all power terminals via shielded cables to suppress EMI .

Maintenance Recommendations: Clean cooling fins quarterly with compressed air. Calibrate control parameters annually using GE DriveTool software. Replace cooling fans every 5 years under 24/7 operation.

Product Assurance

GE provides an 18-month warranty covering material defects. Global technical support includes remote diagnostics and on-site service escalation within 48 hours for critical failures. All units undergo IEC 61800-3 compliance testing for EMC/EMI resilience .

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com