Description

FOXBORO

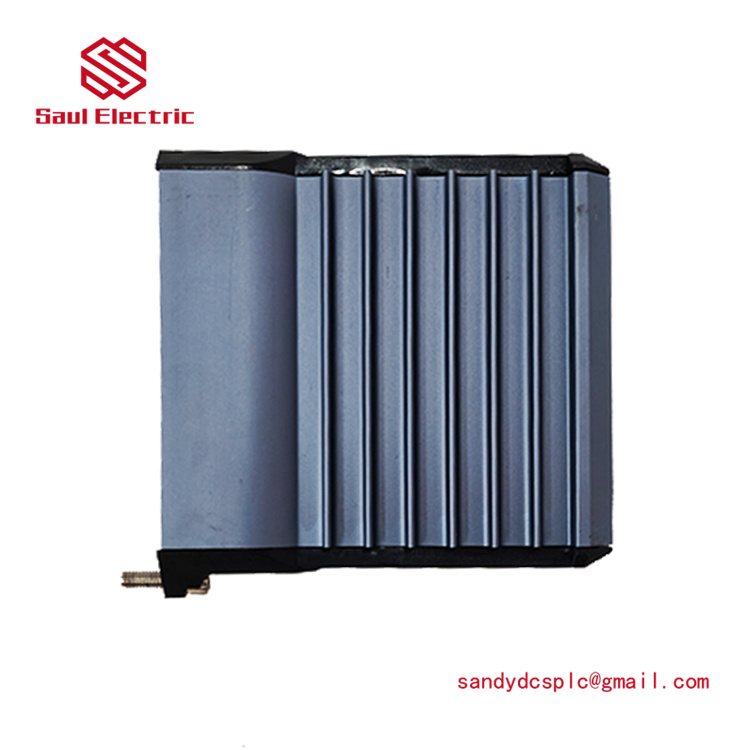

FOXBORO FBM202-P0926EQ-EX Product Description

Product Overview

The FOXBORO FBM202-P0926EQ-EX represents an advanced solution in industrial temperature measurement and process control. As part of the renowned FOXBORO I/A Series, this module is specifically engineered for high-precision thermocouple and millivolt signal acquisition in demanding industrial environments. Its core functionality revolves around providing reliable, accurate temperature data that serves as the foundation for effective process management and automation.

In a typical automation setup, the FOXBORO FBM202-P0926EQ-EX plays a pivotal role as a front-end data acquisition device. It interfaces with various thermocouple types and mV signal sources, converting raw temperature data into standardized signals that can be interpreted and acted upon by higher-level control systems. This makes it indispensable in applications where temperature monitoring is critical to operational efficiency and safety.

What sets the FOXBORO FBM202-P0926EQ-EX apart is its enhanced signal conditioning capabilities, superior noise immunity, and extensive diagnostic features. Unlike standard input modules, this extended model offers improved precision and faster response times, making it suitable for applications that demand exacting temperature control. Its design philosophy centers on maximizing reliability while providing users with the flexibility to configure parameters according to specific process requirements.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | FOXBORO FBM202-P0926EQ-EX |

| Manufacturer | FOXBORO |

| Product Type | Thermocouple/mV Input Module |

| Input Channels | 8 isolated thermocouple/mV channels + 1 RTD reference |

| Signal Compatibility | J, K, T, E, B, S, R, N, C thermocouple types |

| Isolation | Channel-to-channel and channel-to-ground |

| Accuracy | ±0.02% of span (mV channels) |

| RTD Accuracy | ±0.1°C |

| Temperature Coefficient | ±0.005% of span/°C |

| Update Rate | Configurable up to 50 ms per channel |

| Communication | Redundant 2 Mbps module fieldbus |

| Power Requirements | 24 V DC ±5%, 3-5 W consumption |

| Operating Temperature | -20°C to +70°C |

| Protection Rating | IP20 |

| Dimensions | 130 mm x 25 mm x 150 mm |

FBM202-P0926EQ-EX

Key Features and Benefits

The FOXBORO FBM202-P0926EQ-EX stands out in industrial automation due to several innovative features. Its enhanced signal conditioning circuitry delivers exceptional measurement accuracy, crucial for processes where temperature variations of just a few degrees can significantly impact outcomes. The module’s ability to handle multiple thermocouple types without requiring hardware changes offers significant flexibility, reducing inventory costs and simplifying system design.

One of the most notable advantages of the FOXBORO FBM202-P0926EQ-EX is its superior noise rejection capabilities. Through advanced filtering and isolation techniques, it maintains signal integrity even in electrically noisy environments common in industrial settings. This ensures reliable data transmission to control systems, minimizing process disruptions caused by signal interference.

The module’s diagnostic capabilities represent a significant step forward in preventive maintenance. It continuously monitors input connections for open circuits, short circuits, and thermocouple degradation. These diagnostics can be accessed remotely, allowing maintenance teams to address potential issues before they lead to process downtime. This predictive maintenance approach reduces unscheduled stoppages and extends the operational life of both the module and associated equipment.

The FOXBORO FBM202-P0926EQ-EX also excels in system integration. Its compatibility with the FOXBORO I/A Series ecosystem ensures seamless communication with controllers, HMIs, and other intelligent devices. The redundant communication protocol further enhances reliability by providing failover capabilities in case of network issues.

Installation and Maintenance

Installation of the FOXBORO FBM202-P0926EQ-EX requires a standard I/A Series horizontal baseplate with appropriate slot allocation. The module should be positioned away from sources of electromagnetic interference and in an area with adequate airflow for heat dissipation. Proper grounding is essential, following FOXBORO’s specifications to minimize noise ingress. The module can be hot-swapped without disrupting system operation, facilitating easier maintenance.

For optimal performance, the FOXBORO FBM202-P0926EQ-EX should undergo quarterly diagnostic data reviews to identify any developing issues. Annual calibration against certified temperature standards is recommended to maintain measurement accuracy. The module’s filters should be cleaned every six months in environments with high particulate matter. Firmware updates should be applied as released by the manufacturer, with special attention to compatibility with existing system components.

Product Warranty

The FOXBORO FBM202-P0926EQ-EX is backed by a comprehensive 24-month warranty covering manufacturing defects and performance issues under normal operating conditions. FOXBORO’s global support network provides access to technical expertise, replacement units, and on-site service engineers capable of responding to critical issues within 24-48 hours in most regions. The warranty terms reflect FOXBORO’s confidence in the product’s durability and performance capabilities. Customers benefit from the manufacturer’s commitment to continuous improvement, with access to extended warranty options and servicing programs designed to maximize asset uptime throughout the module’s operational life.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com