Description

HIMA F8650E 984865065 Product Description

Product Overview

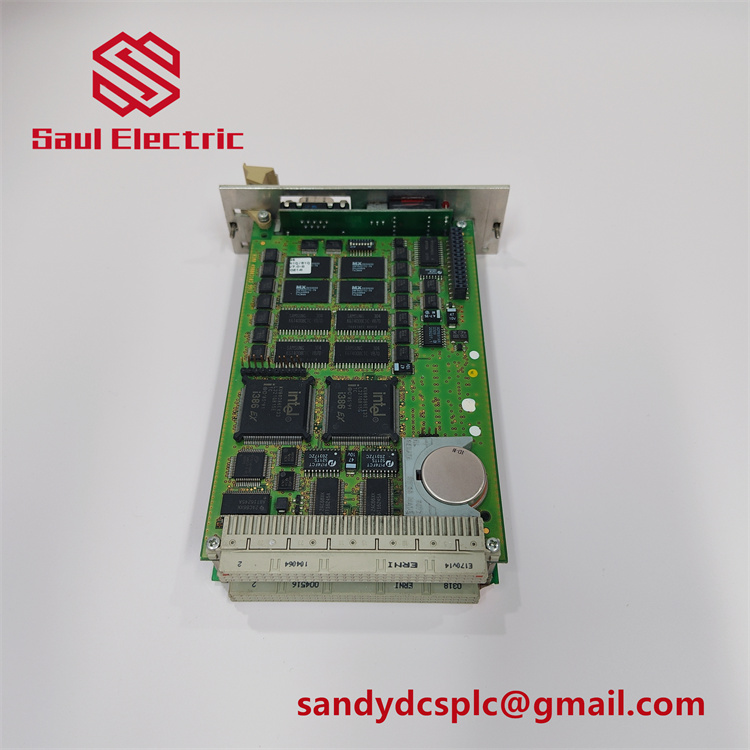

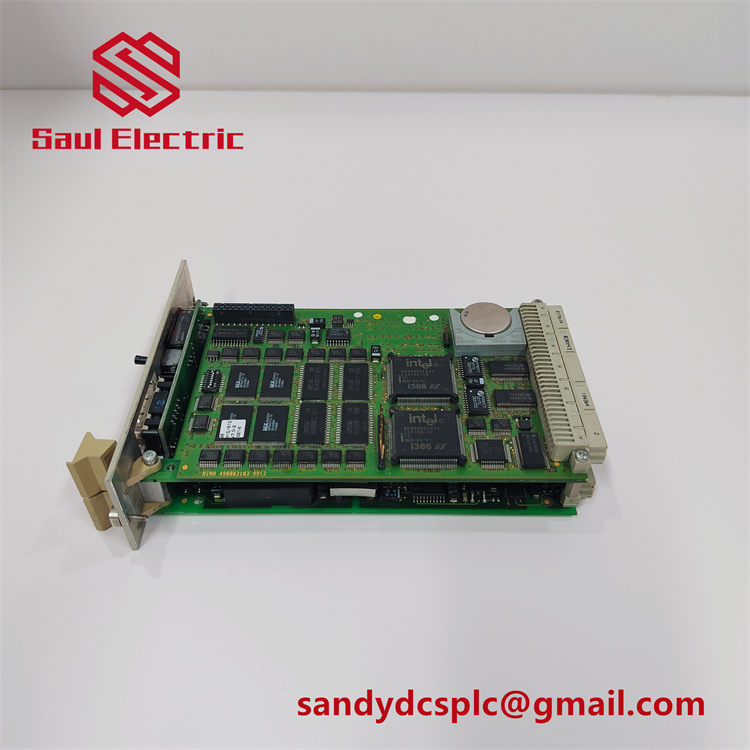

The HIMA F8650E 984865065 is a high-integrity Safety System Central Module engineered for mission-critical industrial applications, designed to serve as the core processing unit in HIMA’s modular safety control systems. As part of HIMA’s F8650 series, this module delivers fault-tolerant control and real-time diagnostics for safety-critical processes, ensuring compliance with the most stringent industry standards.

Featuring dual Intel 386 EX 32-bit microprocessors operating at 25 MHz, the F8650E 984865065 provides clock-synchronized execution to guarantee accurate and reliable performance in environments where downtime is unacceptable. It supports 1 MB of Flash-EPROM for the operating system and 512 KB of Flash-EPROM for user programs, enabling seamless integration with HIMA’s ProVisor® safety runtime environment. The module includes 256 KB of SRAM for data storage and two isolated RS-485 serial interfaces for communication with I/O modules, HMIs, and redundant controllers .

Key functionalities include fail-safe watchdog monitoring, real-time diagnostic feedback, and 24V DC output for load shedding (up to 500 mA), ensuring rapid response to critical events. The module’s 4-digit alphanumeric display and pushbutton interface allow operators to monitor system status, troubleshoot errors, and configure parameters without additional tools. Built with conformal coating and ruggedized components, the F8650E 984865065 withstands extreme temperatures (-25°C to +70°C) and high electromagnetic interference, making it suitable for harsh industrial settings .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | F8650E 984865065 |

| Manufacturer | HIMA Paul Hildebrandt GmbH & Co. KG |

| Product Type | Safety System Central Module (CPU) |

| Processor | Dual Intel 386 EX, 32-bit, 25 MHz |

| Memory | 1 MB Flash-EPROM (OS), 512 KB Flash-EPROM (user), 256 KB SRAM (data) |

| Communication Interfaces | 2 × RS-485 (isolated) |

| Diagnostic Display | 4-digit alphanumeric display with pushbutton controls |

| Power Supply | 24V DC (±15%), 500 mA typical, 2000 mA peak |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 117 mm (width) × 270 mm (height) × 123 mm (depth) [approximate] |

| Weight | 0.34 kg [approximate] |

| Certification | SIL 3 (IEC 61508/61511), CE, FCC |

| Redundancy Support | Hot-swappable in redundant configurations |

| Fault Detection | Watchdog timeout, memory errors, communication failures |

Key Features and Advantages

Safety-Critical Performance: Certified to SIL 3 (IEC 61508/61511), the F8650E 984865065 ensures reliable operation in applications where safety is non-negotiable, such as emergency shutdown systems (ESD) and fire & gas detection. Its dual-processor architecture provides voting logic to validate outputs and prevent single-point failures .

Rugged Industrial Design: The module’s conformal coating and metal oxide varistor (MOV) surge protection shield against voltage transients and environmental contaminants, ensuring stability in oil refineries, chemical plants, and power generation facilities. Its wide temperature range (-25°C to +70°C) supports deployment in extreme climates .

Flexible Integration: With RS-485 connectivity, the F8650E 984865065 interfaces seamlessly with HIMA’s F3300 I/O modules and F8628X communication modules, enabling scalable safety systems. Its modular design allows for easy expansion of I/O channels or integration with third-party devices via gateways .

Advanced Diagnostics: The 4-digit display and LED indicators provide real-time insights into CPU health, communication status, and I/O module integrity. Fault codes are logged for analysis, reducing mean time to repair (MTTR) and minimizing downtime .

Redundancy Capabilities: The module supports hot-swappable redundancy, allowing for system maintenance without process interruption. Redundant power inputs (J1/J2) ensure continuous operation during transient outages .

Application Areas

The HIMA F8650E 984865065 excels in safety-critical scenarios across industries requiring fail-safe control:

- Oil & Gas: Deployed in offshore platforms and refineries to manage ESD systems, compressor controls, and pipeline monitoring. Its SIL 3 certification ensures compliance with API and IEC standards .

- Chemical Processing: Used in batch reactors and distillation units to enforce interlocks, prevent overpressure, and mitigate risks of hazardous releases. The module’s diagnostic capabilities help maintain ISO 14001 environmental compliance .

- Power Generation: Integrates with steam turbine control systems to monitor critical parameters (e.g., vibration, temperature) and trigger shutdowns to protect equipment from catastrophic failure .

- Pharmaceuticals: Ensures sterile environment integrity in bioreactors and filling lines by controlling cleanroom airflow and alarm systems, adhering to FDA and EU GMP regulations .

Related Products

- F8650X: A higher-performance variant with Ethernet connectivity and extended memory, suitable for complex systems requiring real-time data exchange .

- F3300: A high-speed I/O module that pairs with the F8650E 984865065 to provide analog and digital signal conditioning for field devices .

- F8628X: A Ethernet communication module enabling integration with HMI systems and cloud-based analytics platforms .

- F7131: A power distribution module that supplies redundant 24V DC power to the F8650E 984865065 and downstream I/O modules .

- F8621A: A coprocessor module that offloads non-safety-related tasks, optimizing the F8650E 984865065 for critical control functions .

Installation and Maintenance

Installation Preparation:

Ensure the control cabinet is properly grounded and ventilated. Align the F8650E 984865065 with the backplane connectors, pressing firmly until the retention clips engage. Connect 24V DC power to terminals J1 and J2 for redundancy. Use #18 AWG shielded cables for RS-485 communication, terminating with 120Ω resistors at both ends. Configure the module’s address via dip switches and verify compatibility with HIMA’s ProVisor® software .

Ensure the control cabinet is properly grounded and ventilated. Align the F8650E 984865065 with the backplane connectors, pressing firmly until the retention clips engage. Connect 24V DC power to terminals J1 and J2 for redundancy. Use #18 AWG shielded cables for RS-485 communication, terminating with 120Ω resistors at both ends. Configure the module’s address via dip switches and verify compatibility with HIMA’s ProVisor® software .

Maintenance Recommendations:

Regularly inspect the module for loose connections or signs of corrosion. Clean the display and vents with a dry cloth to prevent dust buildup. Monitor diagnostic codes via the 4-digit display and replace faulty components immediately. HIMA recommends annual firmware updates to address security patches and enhance functionality. For offline testing, use HIMA’s Simulator Tool to validate control logic and response times .

Regularly inspect the module for loose connections or signs of corrosion. Clean the display and vents with a dry cloth to prevent dust buildup. Monitor diagnostic codes via the 4-digit display and replace faulty components immediately. HIMA recommends annual firmware updates to address security patches and enhance functionality. For offline testing, use HIMA’s Simulator Tool to validate control logic and response times .

Product Warranty and Support

HIMA guarantees the F8650E 984865065 against defects in materials and workmanship for 1 year from the date of purchase. This warranty covers replacement or repair of the module if deemed faulty under normal use. Customers gain access to HIMA’s global technical support network, including 24/7 remote diagnostics, on-site training, and access to a vast library of technical documentation (e.g., datasheets, wiring diagrams) .

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com