Description

Product Overview

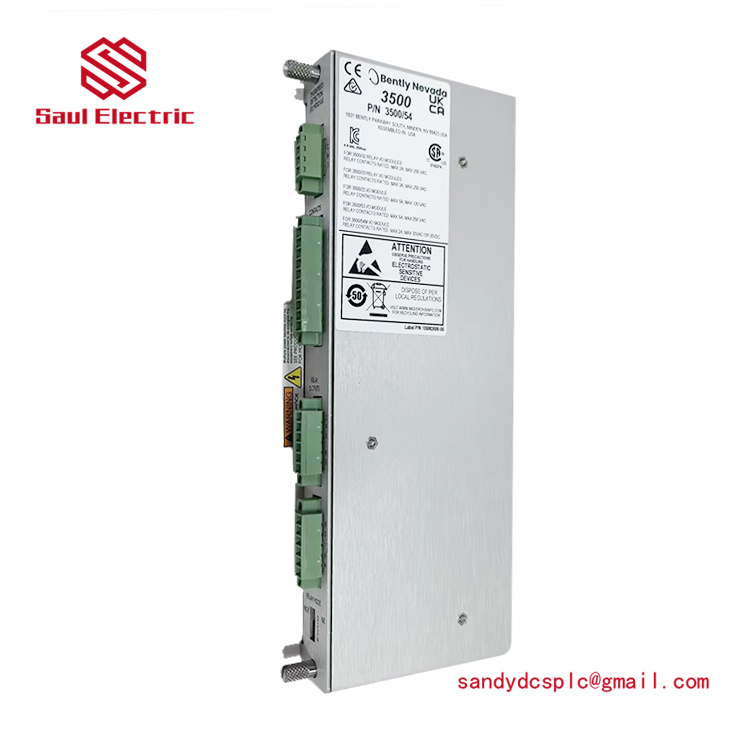

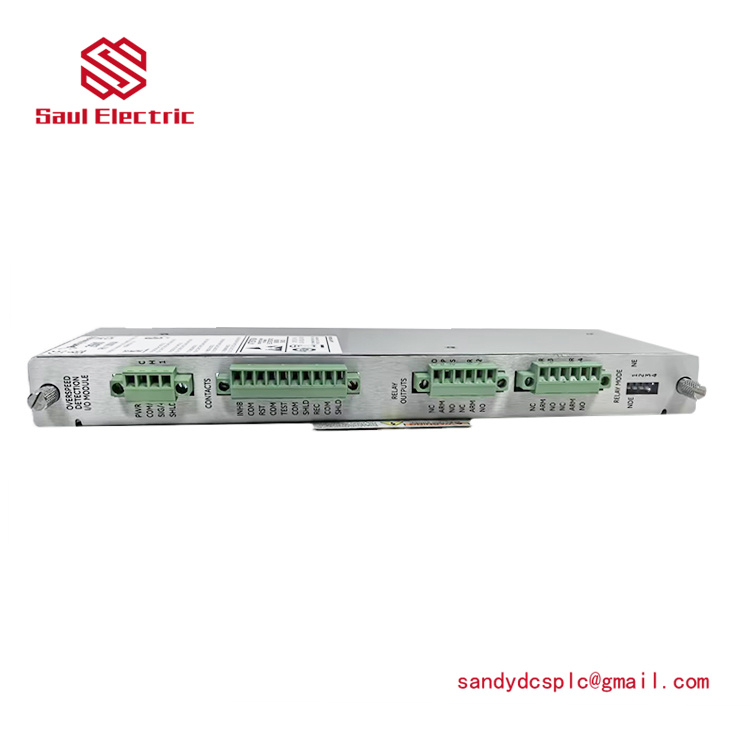

The Bently Nevada 3500/54 133396-01 is a dual-channel speed monitoring module critical to machinery protection systems in critical industrial environments. As part of the Bently Nevada 3500 series, it provides precise rotational speed measurement and overspeed protection for turbines, compressors, pumps, and other high-speed rotating equipment. It processes signals from proximity probes, magnetic pickups, or tachometers, delivering real-time speed data and triggering alarms or shutdowns to prevent catastrophic failures. Its dual-channel redundancy ensures continuous operation even during sensor or channel faults, aligning with SIL 2 safety standards (IEC 61508/61511) for critical applications.

3500/54 133396-01

Application Scenarios

The Bently Nevada 3500/54 133396-01 is critical in industries requiring rigorous speed monitoring. In power generation, it provides overspeed protection for gas/steam turbines and turboexpanders. In the oil and gas sector, it controls compressor and pump speeds in upstream and midstream operations. In petrochemical plants, it safeguards centrifugal compressors and gearboxes in ethylene plants.

3500/54 133396-01

Installation and Maintenance

Prior to installing the Bently Nevada 3500/54 133396-01, ensure the installation site meets its environmental requirements, such as temperature, humidity, and dust levels. The installation location should allow convenient wiring and maintenance. The module must be installed within a 3500 series monitoring system frame and used in conjunction with power modules, interface modules, and other components. During installation, follow the manufacturer’s guidelines to ensure proper grounding and secure connections.

3500/54 133396-01

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com