Description

Key Features and Benefits

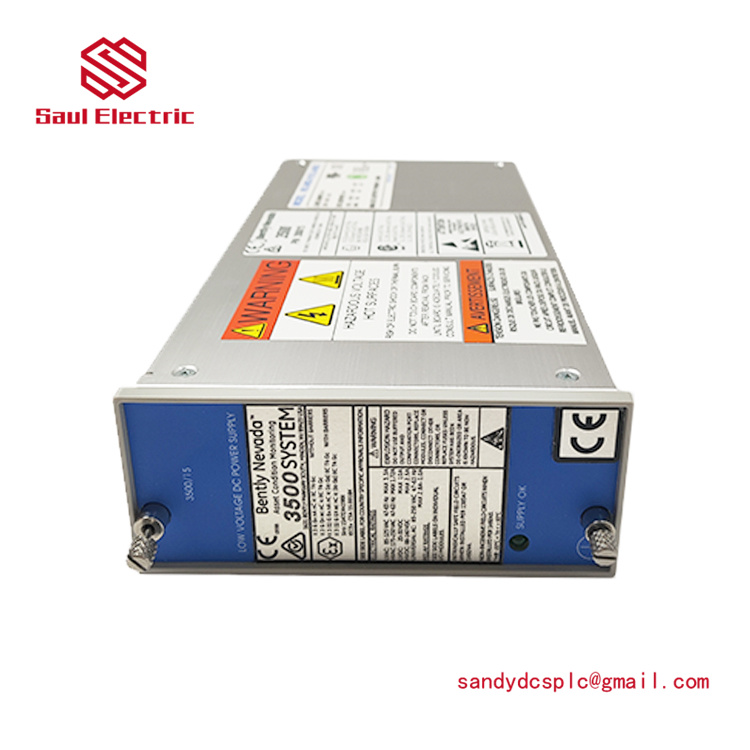

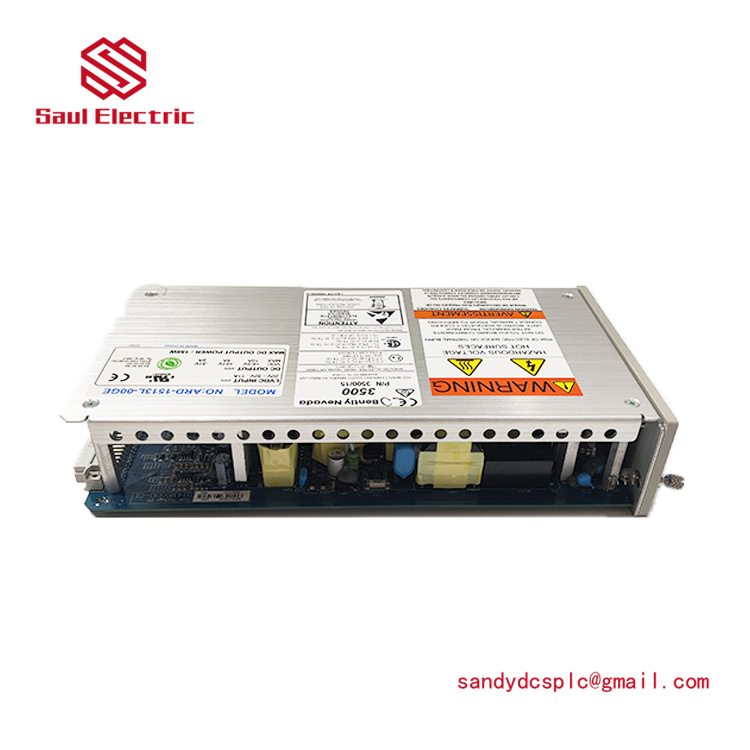

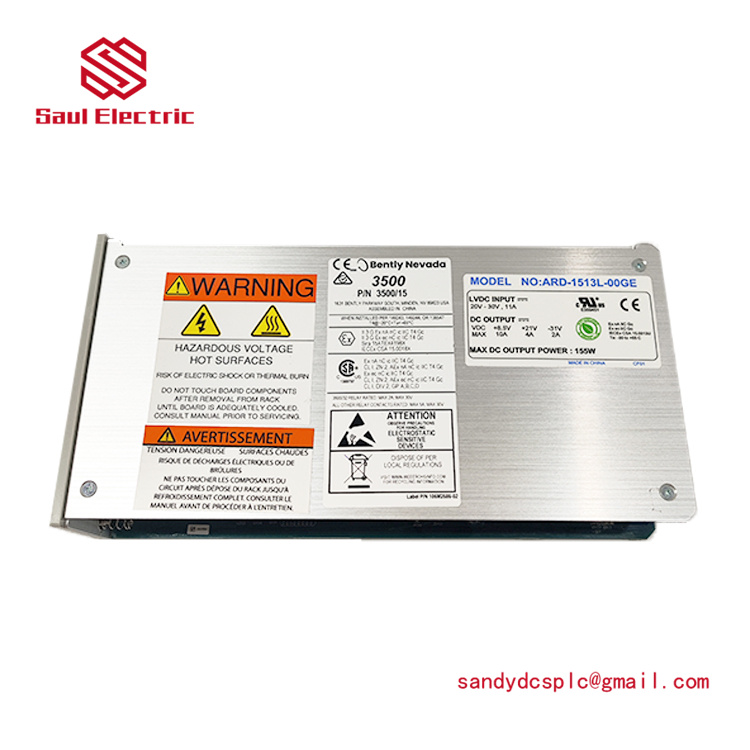

The BENTLY 3500/15 114M5330-01 offers exceptional signal processing capabilities, with a 25.6 kS/s sampling rate that captures even the subtlest changes in machinery vibration patterns. This high-resolution data acquisition enables early detection of issues such as bearing wear, misalignment, and imbalance, providing maintenance teams with sufficient time to schedule repairs before catastrophic failure occurs. Its wide measurement range of ±200 mV accommodates various vibration signal amplitudes, ensuring accurate monitoring across different machine types and operating conditions.

Application Scenarios

In power generation facilities, the BENTLY 3500/15 114M5330-01 is indispensable for monitoring the condition of steam turbines and generators. By analyzing high-frequency vibration signals, it detects early signs of bearing deterioration, rotor imbalance, and shaft misalignment, allowing for timely maintenance interventions that prevent costly unplanned outages. In oil & gas refineries, the module is used to monitor compressors and pumps operating under harsh conditions. Its ability to detect subtle changes in vibration patterns helps identify issues such as cavitation, impeller damage, and bearing wear, ensuring reliable operation of critical equipment.

114M5330-01

Installation and Maintenance

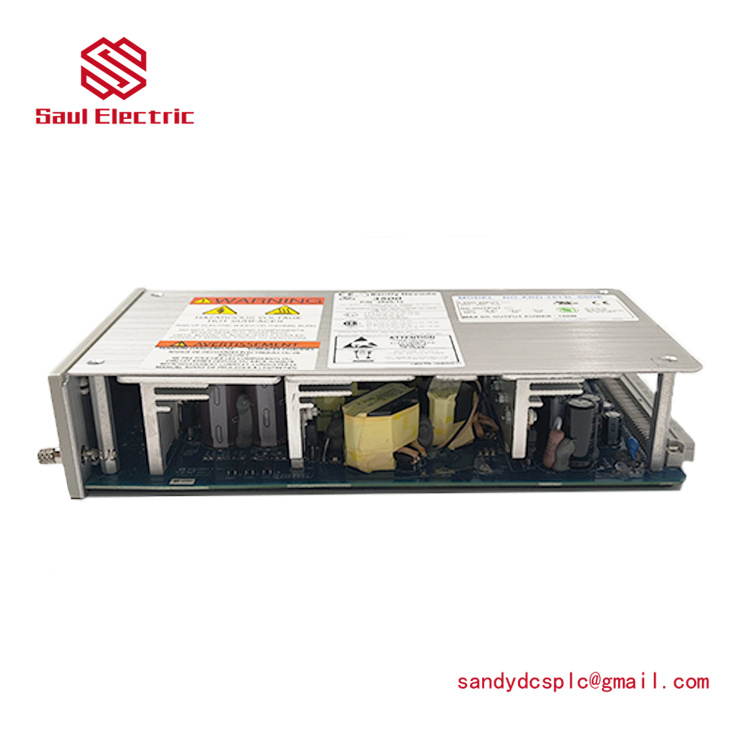

When installing the BENTLY 3500/15 114M5330-01, ensure the location is selected based on vibration sensor placement requirements, with minimal interference from external electrical noise sources. The module should be mounted in a well-ventilated area within its operating temperature range of -30°C to +85°C. Use shielded cables for all connections to minimize electromagnetic interference. Secure the module to a standard 35mm DIN rail using the provided hardware. Connect vibration sensors to the module’s input channels, ensuring proper calibration and tight connections.

114M5330-01

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com