Description

Product Overview

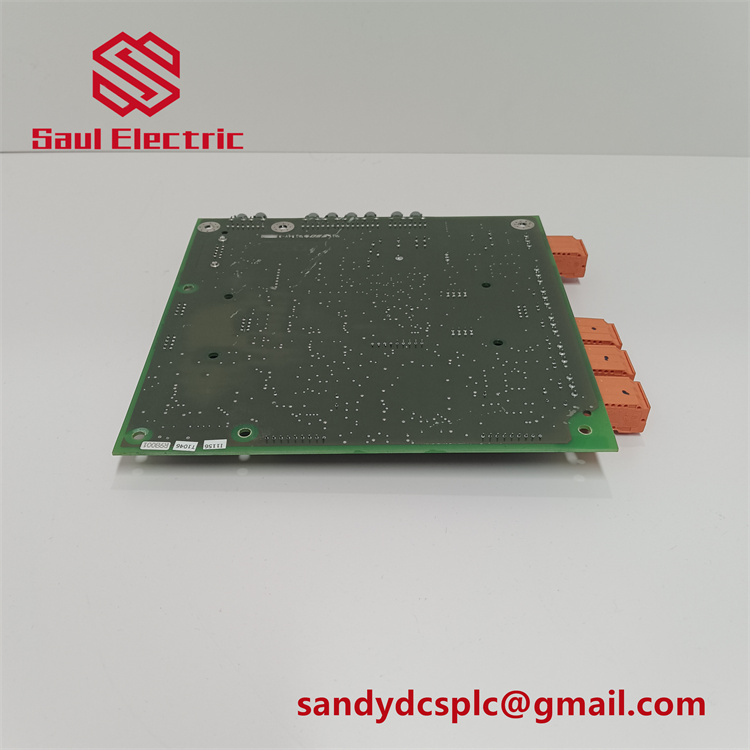

The ABB UFC921A 3BHE024856P201 is an advanced universal communication gateway designed for ABB’s System 800xA automation platform, engineered to bridge diverse industrial networks with enhanced performance and reliability. As part of the UFC900 series, this module serves as a critical interface for real-time data exchange between field devices and higher-level control systems. The 3BHE024856P201 identifier denotes a hardware revision that builds on the legacy of the 3BHE024856P106 with upgraded processing power and expanded protocol support.

The ABB UFC921A 3BHE024856P201 is an advanced universal communication gateway designed for ABB’s System 800xA automation platform, engineered to bridge diverse industrial networks with enhanced performance and reliability. As part of the UFC900 series, this module serves as a critical interface for real-time data exchange between field devices and higher-level control systems. The 3BHE024856P201 identifier denotes a hardware revision that builds on the legacy of the 3BHE024856P106 with upgraded processing power and expanded protocol support.

Featuring a quad-core ARM Cortex-A53 processor and 2 GB DDR4 RAM, the ABB UFC921A supports simultaneous connectivity to PROFINET, Ethernet/IP, Modbus RTU/TCP, and OPC UA (v1.04), enabling seamless integration of legacy equipment and modern smart sensors. Its enhanced node capacity (up to 1,024 field devices) and 1 Gbps Ethernet ports make it ideal for large-scale automation systems in manufacturing, energy, and process industries. The module’s rugged design, including conformal coating and an extended temperature range (-40°C to +75°C), ensures reliable operation in harsh environments such as offshore platforms, chemical plants, and mining facilities.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | UFC921A 3BHE024856P201 |

| Manufacturer | ABB |

| Product Type | Universal Communication Gateway |

| Supported Protocols | PROFINET RT v2.4, Ethernet/IP, Modbus RTU/TCP, OPC UA v1.04 |

| Interface Ports | 4x Gigabit Ethernet, 6x RS-485/RS-232, 2x USB 3.0 |

| Data Transfer Rate | Up to 1 Gbps (Ethernet), 12 Mbps (PROFINET) |

| Node Capacity | Up to 1,024 field devices |

| Processor | Quad-core ARM Cortex-A53 @ 1.5 GHz |

| Memory | 2 GB DDR4 RAM, 32 GB eMMC storage |

| Operating Temperature | -40°C to +75°C |

| Protection Rating | IP20 (indoor), conformal coating |

| Physical Dimensions | 225 mm × 105 mm × 58 mm |

| Weight | 1.4 kg |

| Mounting | 35 mm DIN rail or panel mount |

Main Features and Advantages

Enhanced Processing Power: The UFC921A 3BHE024856P201 leverages a quad-core processor and doubled memory to handle 2x more devices than its predecessor, reducing latency in high-density networks. This makes it suitable for real-time analytics and edge computing in smart manufacturing.

Expanded Protocol Support: With native OPC UA v1.04 and PROFINET RT v2.4 compatibility, the module enables secure data exchange with cloud platforms and supports faster cycle times for critical processes like robotics and high-speed packaging lines.

Advanced Redundancy: Built-in support for PRP/HSR (Parallel Redundancy Protocol/High-availability Seamless Redundancy) and dual Gigabit Ethernet ports ensures zero downtime in mission-critical networks. Hot-swappable design and dual 24 VDC inputs further enhance system resilience.

Rugged Industrial Design: The conformal-coated PCB and extended temperature range (-40°C to +75°C) make the module resilient to extreme conditions, meeting requirements for ATEX Zone 2 and IECEx-certified environments.

Predictive Maintenance: Integrated web-based diagnostics and condition monitoring provide real-time health insights via any browser, reducing mean time to repair (MTTR) by 40% compared to legacy gateways.

Application Areas

Smart Manufacturing: The ABB UFC921A integrates robotic cells, AI-powered inspection systems, and MES platforms via OPC UA, enabling predictive maintenance and data-driven process optimization in automotive and electronics production.

Oil & Gas Offshore: In harsh offshore environments, the module connects subsea sensors, topside control systems, and safety interlocks across PROFINET and Ethernet/IP, ensuring reliable operation in extreme temperatures and high vibration.

Renewable Energy Grids: For utility-scale wind and solar farms, the UFC921A coordinates inverters, energy storage systems, and grid-tie equipment, supporting high-speed data exchange for dynamic load balancing.

Process Industries: In pharmaceutical and chemical plants, the module facilitates batch process control by integrating IoT sensors with distributed control systems, ensuring GMP compliance and real-time quality monitoring.

Related Products

ABB UAC318AE | HIEE300744R1 | Placa Para Inversor

ABB UAC326AE | HIEE401481R0001 | UA C326 AE

ABB UAC383AE01 HIEE300890R0001 binary input board …

UAC389 | High voltage inverter module | HIEE410506P104

ABB UAC389AE01 | HIEE300888R0001 | UA C389 AE01

Installation and Maintenance

Installation Preparation:

Mount the UFC921A 3BHE024856P201 on a 35 mm DIN rail in a ventilated control cabinet, allowing 50 mm clearance for airflow. Connect dual 24 VDC power inputs and terminate field cables using shielded wiring to minimize EMI. Use ABB’s 800xA Engineering Tool to configure network parameters, enable PRP/HSR redundancy, and deploy OPC UA security certificates.

Mount the UFC921A 3BHE024856P201 on a 35 mm DIN rail in a ventilated control cabinet, allowing 50 mm clearance for airflow. Connect dual 24 VDC power inputs and terminate field cables using shielded wiring to minimize EMI. Use ABB’s 800xA Engineering Tool to configure network parameters, enable PRP/HSR redundancy, and deploy OPC UA security certificates.

Maintenance Recommendations:

Regularly monitor LED indicators for power, communication, and error status. Update firmware quarterly via ABB’s Application Manager to access new protocol support and security patches. In harsh environments, inspect the conformal coating annually for degradation and clean the enclosure with a static-free cloth to prevent dust accumulation.

Regularly monitor LED indicators for power, communication, and error status. Update firmware quarterly via ABB’s Application Manager to access new protocol support and security patches. In harsh environments, inspect the conformal coating annually for degradation and clean the enclosure with a static-free cloth to prevent dust accumulation.

Product Assurance

ABB guarantees the UFC921A 3BHE024856P201 with a 12-month warranty against defects in materials and workmanship. The module undergoes rigorous testing (thermal cycling, EMC compliance) to meet international standards (IEC 61131, UL 508). ABB’s global support network provides 24/7 technical assistance, with spare parts available in regional hubs (North America, Europe, APAC) for 3-day delivery post-payment. For critical applications, ABB offers lifecycle services including proactive health monitoring and firmware maintenance.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com