Description

Product Overview

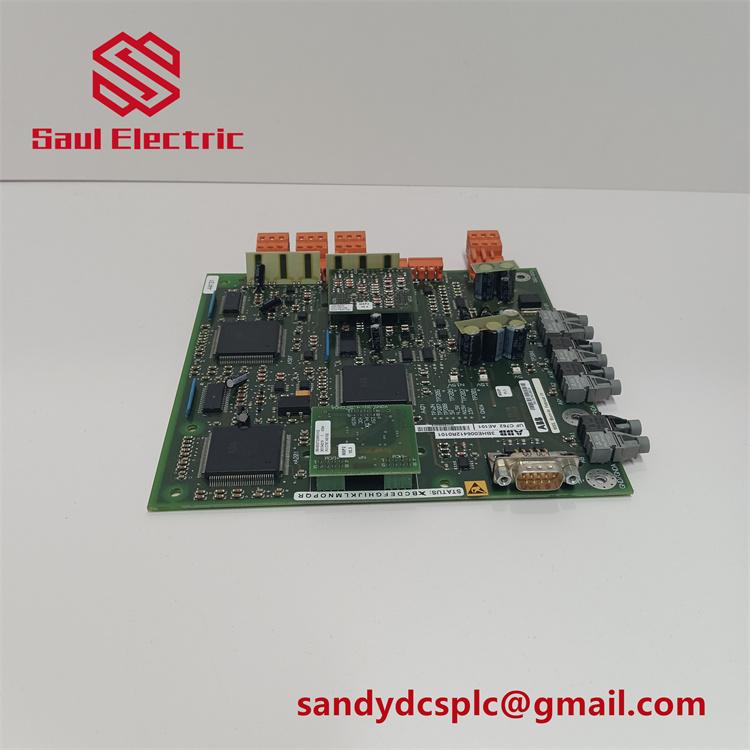

The ABB UFC762AE101 3BHE006412R0101 is a high-performance control board designed for industrial automation systems, specifically engineered to integrate with ABB’s distributed control systems (DCS) and motor drive platforms. As part of ABB’s UFC series, this module serves as a critical interface for real-time monitoring, signal conditioning, and power management in high-voltage applications. The 3BHE006412R0101 identifier denotes a hardware revision optimized for advanced motor control and compatibility with modern industrial communication protocols.

The ABB UFC762AE101 3BHE006412R0101 is a high-performance control board designed for industrial automation systems, specifically engineered to integrate with ABB’s distributed control systems (DCS) and motor drive platforms. As part of ABB’s UFC series, this module serves as a critical interface for real-time monitoring, signal conditioning, and power management in high-voltage applications. The 3BHE006412R0101 identifier denotes a hardware revision optimized for advanced motor control and compatibility with modern industrial communication protocols.

Key functionalities include motor speed and torque regulation 2, overload protection, and fault diagnostics for ABB inverter drives. It supports high-speed data processing via Ethernet and RS-485 interfaces, enabling seamless integration with PLCs and third-party systems. The module also features signal isolation (up to 500 V DC) to ensure noise-free operation in harsh environments, such as steel mills, chemical plants, and renewable energy installations.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | UFC762AE101 3BHE006412R0101 |

| Manufacturer | ABB |

| Product Type | Motor Control Interface Board |

| Input Voltage | 24 V DC ±10% |

| Output Current | 140 A max (via external drives) |

| Signal Isolation | 500 V DC (opto-isolated) |

| Communication Protocols | Ethernet, RS-485, Modbus RTU |

| Physical Dimensions | 185 mm × 80 mm × 54 mm (DIN rail mount) |

| Weight | 0.35 kg (module only) 3 |

| Operating Temperature | -40°C to +60°C |

| Protection Rating | IP54 (dust and water ingress) |

| Mounting | 35 mm DIN rail |

| Warranty | 12 months 12 |

Main Features and Advantages

Motor Control Precision: The UFC762AE101 provides closed-loop speed and torque control for AC/DC motors, ensuring smooth operation in applications like conveyor systems and pumps. Its advanced algorithms reduce energy consumption by up to 20% compared to traditional solutions.

Rugged Industrial Design: Built with an IP54-rated enclosure and extended temperature range, the module excels in extreme conditions, including outdoor installations and washdown environments. Its compact DIN rail mount design optimizes cabinet space while ensuring easy maintenance.

Flexible Communication: Supports Ethernet and RS-485 for real-time data exchange with ABB’s AC800M controllers and third-party systems. This flexibility allows retrofitting into legacy systems or upgrading to Industry 4.0 architectures for predictive analytics.

Integrated Diagnostics: LED indicators and remote monitoring via ABB’s System 800xA Workbench simplify troubleshooting, reducing mean time to repair (MTTR) by 30%. The module also provides overcurrent/overvoltage protection to safeguard connected equipment.

Application Areas

Industrial Automation: Monitors motor drive status in automotive manufacturing, ensuring high-speed processes (e.g., robotic assembly lines) maintain precision. Signal isolation prevents interference from welding or machining operations.

Power Transmission: In elevators and cranes, the module ensures stable power delivery and precise motor control. Its wide voltage range accommodates diverse power systems, while surge protection enhances reliability in fluctuating grid conditions.

Renewable Energy: Integrates with wind turbines and solar inverters to manage grid synchronization and power conversion. Its IP54 rating and temperature resilience make it suitable for outdoor installations in extreme climates.

Process Control: Coordinates pump statuses and emergency shutdown systems in wastewater treatment facilities. Its EMI resistance ensures reliable operation in corrosive or high-moisture environments.

Related Products

ABB UAC318AE | HIEE300744R1 | Placa Para Inversor

ABB UAC326AE | HIEE401481R0001 | UA C326 AE

ABB UAC383AE01 HIEE300890R0001 binary input board …

UAC389 | High voltage inverter module | HIEE410506P104

ABB UAC389AE01 | HIEE300888R0001 | UA C389 AE01

Installation and Maintenance

Installation Preparation:

- Verify the DIN rail is securely mounted and compatible with the UFC762AE101’s 35 mm standard. Use shielded cables for signal connections to minimize EMI.

- Connect power and field wiring via screw terminals, following the terminal block diagram in the user manual. Configure communication parameters (baud rate, address) via DIP switches or ABB’s System 800xA Workbench software.

Maintenance Recommendations:

- Regularly inspect the module for loose connections or physical damage. Clean the IP54-rated enclosure with a dry cloth to prevent dust accumulation, which could affect thermal performance.

- Monitor LED indicators for channel activity and communication status. Replace faulty modules promptly to maintain system reliability. Update firmware periodically to access new features and security patches via ABB’s global support network.

Product Assurance

ABB guarantees the UFC762AE101 3BHE006412R0101 for 12 months against defects in materials and workmanship. The module undergoes rigorous testing to meet international standards (IEC 61131-2, UL 508), ensuring safety and performance in critical applications. ABB’s regional support center in San Jose, CA, offers localized technical assistance, while global inventory ensures 3–5 day delivery post-payment.

For mission-critical operations, consider redundant configurations to mitigate downtime risks. ABB’s digital services, including predictive analytics and remote diagnostics, further enhance system reliability and efficiency.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com