Description

Product Overview

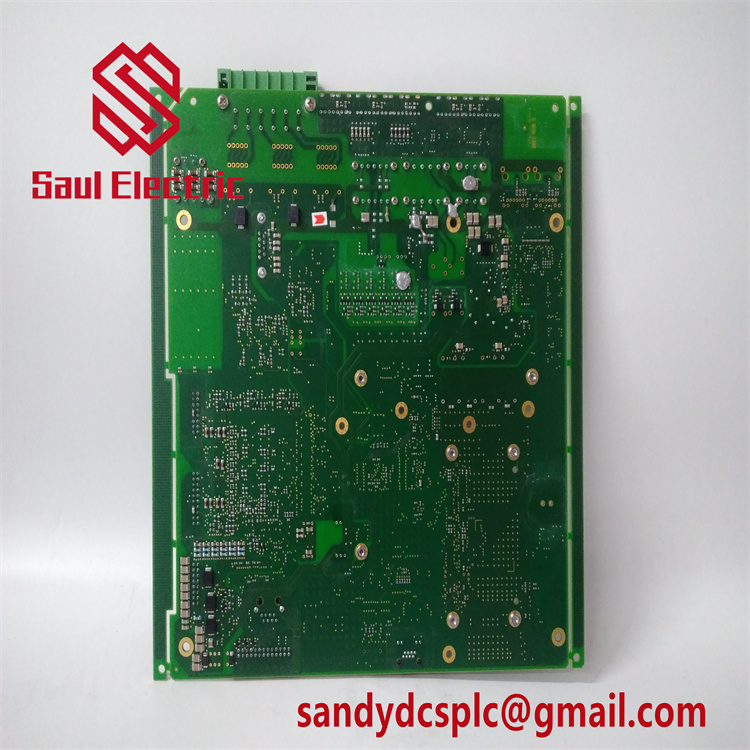

The ABB UCD224A102 is a high-performance 16-channel digital input/output (DIO) module engineered for industrial automation systems, specifically designed for integration with ABB’s ControlLine series and distributed control systems (DCS). As a critical component of the UCD family, this module bridges the gap between field devices (sensors and actuators) and control systems, enabling precise data acquisition and command execution in process industries. The UCD224A102 combines advanced signal conditioning with rugged construction, ensuring reliable operation in harsh environments while maintaining compatibility with ABB’s ecosystem of controllers, HMIs, and software tools.

The ABB UCD224A102 is a high-performance 16-channel digital input/output (DIO) module engineered for industrial automation systems, specifically designed for integration with ABB’s ControlLine series and distributed control systems (DCS). As a critical component of the UCD family, this module bridges the gap between field devices (sensors and actuators) and control systems, enabling precise data acquisition and command execution in process industries. The UCD224A102 combines advanced signal conditioning with rugged construction, ensuring reliable operation in harsh environments while maintaining compatibility with ABB’s ecosystem of controllers, HMIs, and software tools.

With a 24 V DC input voltage range and 5 mA maximum input current, the module efficiently converts analog sensor signals into digital data for real-time monitoring of processes such as temperature, pressure, and valve positions. Its <10 ms response time ensures rapid feedback for critical applications like emergency shutdowns or quality control checks. The 16-channel configuration (8 inputs + 8 outputs) allows for dense I/O integration, reducing cabinet space and cabling complexity in large-scale installations.

Built to withstand industrial-grade conditions, the UCD224A102 features a compact design (dimensions: 120 mm × 80 mm × 60 mm) and IP20-rated housing, protecting against dust and accidental contact. It operates seamlessly within a -20°C to +60°C temperature range, making it suitable for extreme climates. Backed by ABB’s rigorous testing, this module delivers long-term reliability in sectors such as oil and gas, chemical processing, and power generation, where downtime is costly.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | UCD224A102 |

| Manufacturer | ABB |

| Product Type | 16-Channel Digital I/O Module (ControlLine) |

| Input Voltage Range | 24 V DC |

| Input Current | 5 mA max |

| Output Voltage | 24 V DC (isolated) |

| Response Time | <10 ms |

| Channel Configuration | 16 channels (8 inputs + 8 outputs) |

| Signal Isolation | 500 V DC (input/output to system ground) |

| Physical Dimensions | 120 mm (L) × 80 mm (W) × 60 mm (H) |

| Weight | 0.5 kg |

| Operating Temperature | -20°C to +60°C |

| Communication Protocol | PROFIBUS DP/PA, Modbus RTU/TCP |

| Mounting | DIN rail (35 mm standard) |

| Warranty | 12 months |

Key Features and Advantages

High-Density I/O Integration: The UCD224A102 consolidates 16 I/O channels into a single compact module, optimizing space in control cabinets and reducing wiring complexity. This design is ideal for applications requiring large-scale data acquisition, such as batch processing or multi-loop control systems.

High-Density I/O Integration: The UCD224A102 consolidates 16 I/O channels into a single compact module, optimizing space in control cabinets and reducing wiring complexity. This design is ideal for applications requiring large-scale data acquisition, such as batch processing or multi-loop control systems.

Fast Response and Precision: With a <10 ms response time, the module ensures real-time data transmission, critical for time-sensitive processes like conveyor belt synchronization or safety interlocks. Its ±0.1% signal accuracy minimizes measurement errors, enhancing process consistency.

Rugged Reliability: Engineered for harsh environments, the module’s IP20-rated enclosure and wide temperature range (-20°C to +60°C) ensure stable performance in dusty, humid, or high-vibration settings. This resilience reduces maintenance costs and extends operational lifespan.

Seamless System Integration: As part of ABB’s ControlLine series, the UCD224A102 integrates seamlessly with ABB’s AC800M controllers and engineering tools like System 800xA Workbench. This interoperability streamlines system commissioning and enables centralized diagnostics, improving overall efficiency.

Applications

The ABB UCD224A102 excels in diverse industrial applications requiring reliable digital I/O management:

The ABB UCD224A102 excels in diverse industrial applications requiring reliable digital I/O management:

- Process Automation: Monitors and controls valves, pumps, and motors in chemical plants, refineries, and water treatment facilities, ensuring optimal process flow and regulatory compliance.

- Manufacturing: Coordinates robotic assembly lines, quality inspection systems, and material handling equipment in automotive and electronics manufacturing, enhancing productivity and product consistency.

- Power Generation: Supports turbine control, boiler management, and grid synchronization in power plants, enabling efficient energy production and distribution.

- Oil and Gas: Manages wellhead monitoring, pipeline pressure control, and emergency shutdown systems in upstream and downstream operations, ensuring safety and operational continuity.

- Pharmaceuticals: Maintains sterile environments by controlling HVAC systems, cleanroom access, and batch sterilization processes, adhering to strict regulatory standards.

Related Products

ABB UAC318AE | HIEE300744R1 | Placa Para Inversor

ABB UAC326AE | HIEE401481R0001 | UA C326 AE

ABB UAC383AE01 HIEE300890R0001 binary input board …

UAC389 | High voltage inverter module | HIEE410506P104

ABB UAC389AE01 | HIEE300888R0001 | UA C389 AE01

Installation and Maintenance

Installation Preparation:

Before installing the UCD224A102, ensure the environment meets ABB’s specifications: a clean, dry location with ambient temperature between -20°C and +60°C. Mount the module securely on a 35 mm DIN rail using torque-rated screws (0.8–1.2 N·m). Verify proper grounding and connect the 24 V DC power supply and field wiring according to the terminal block diagram provided in the user manual.

Installation Preparation:

Before installing the UCD224A102, ensure the environment meets ABB’s specifications: a clean, dry location with ambient temperature between -20°C and +60°C. Mount the module securely on a 35 mm DIN rail using torque-rated screws (0.8–1.2 N·m). Verify proper grounding and connect the 24 V DC power supply and field wiring according to the terminal block diagram provided in the user manual.

Maintenance Recommendations:

Regularly inspect the module for loose connections, corrosion, or physical damage. Use ABB’s diagnostic tools to monitor channel status and signal integrity. Clean the enclosure with a dry cloth to prevent dust accumulation. For long-term use, consider implementing redundant I/O configurations to mitigate downtime risks. ABB’s global support network provides firmware updates and technical guidance to optimize performance.

Regularly inspect the module for loose connections, corrosion, or physical damage. Use ABB’s diagnostic tools to monitor channel status and signal integrity. Clean the enclosure with a dry cloth to prevent dust accumulation. For long-term use, consider implementing redundant I/O configurations to mitigate downtime risks. ABB’s global support network provides firmware updates and technical guidance to optimize performance.

Product Assurance

ABB guarantees the UCD224A102 with a 12-month warranty covering defects in materials and workmanship. Our certified technicians offer 24/7 technical support, including remote diagnostics and on-site assistance. With spot inventory available, orders are fulfilled within 3–5 days of payment, ensuring minimal project delays. Trust ABB’s legacy of innovation and reliability to deliver a high-performance solution for your industrial automation needs.

ABB guarantees the UCD224A102 with a 12-month warranty covering defects in materials and workmanship. Our certified technicians offer 24/7 technical support, including remote diagnostics and on-site assistance. With spot inventory available, orders are fulfilled within 3–5 days of payment, ensuring minimal project delays. Trust ABB’s legacy of innovation and reliability to deliver a high-performance solution for your industrial automation needs.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com