Description

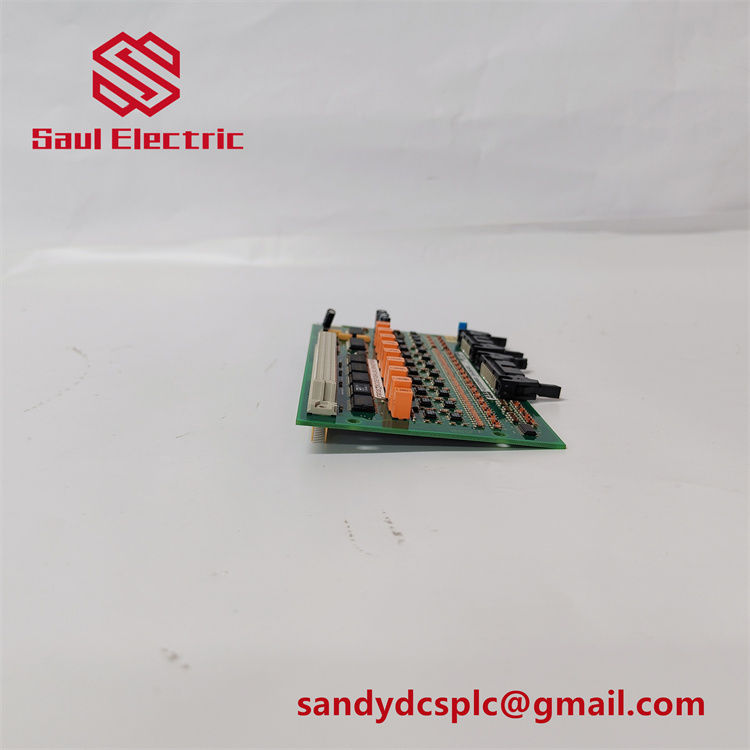

ABB UAC326AE Industrial Automation Controller Module

Product Overview

The ABB UAC326AE is a high-performance industrial automation controller module designed for mission-critical applications requiring precise control and real-time data processing. As part of ABB’s advanced automation portfolio, this module serves as a core component in distributed control systems (DCS) and programmable logic controllers (PLCs), enabling seamless integration with field devices, HMIs, and SCADA systems.

Featuring a 32-bit RISC processor and dual-core architecture, the ABB UAC326AE delivers robust computational power for executing complex control algorithms, including PID regulation, sequential logic, and motion control . Its modular design supports scalable expansion through up to 800 I/O points, accommodating diverse industrial scenarios such as motor control, process optimization, and equipment monitoring. The module incorporates high-frequency PWM technology to minimize power loss and reduce electromagnetic interference, ensuring stable operation in electrically noisy environments . With support for multiple communication protocols (Modbus TCP, PROFINET, EtherNet/IP), it facilitates interoperability with third-party devices, enhancing system flexibility .

The ABB UAC326AE is engineered for reliability, with a wide operating temperature range (-25°C to +70°C) and IP40-rated enclosure, making it suitable for harsh industrial environments . Its self-diagnostic tools and hot-swappable components enable proactive maintenance, reducing mean time to repair (MTTR) and maximizing uptime. Certified to meet international standards (CE, UL, CSA), this module ensures compliance with safety and environmental regulations in industries like oil & gas, power generation, and chemical processing. By combining advanced hardware with software-driven adaptability, the ABB UAC326AE empowers industries to achieve operational excellence and digital transformation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB UAC326AE |

| Manufacturer | ABB |

| Product Type | Industrial Automation Controller Module |

| Processor | 32-bit RISC dual-core CPU |

| Memory | 8 MB user memory, 0.98 MB I/O memory |

| Input/Output Channels | Configurable via modular expansion |

| Communication Protocols | Modbus TCP, PROFINET, EtherNet/IP, RS-232/485 |

| Power Supply | 24 VDC ±10% (isolated) |

| Operating Temperature | -25°C to +70°C |

| Enclosure Rating | IP40 |

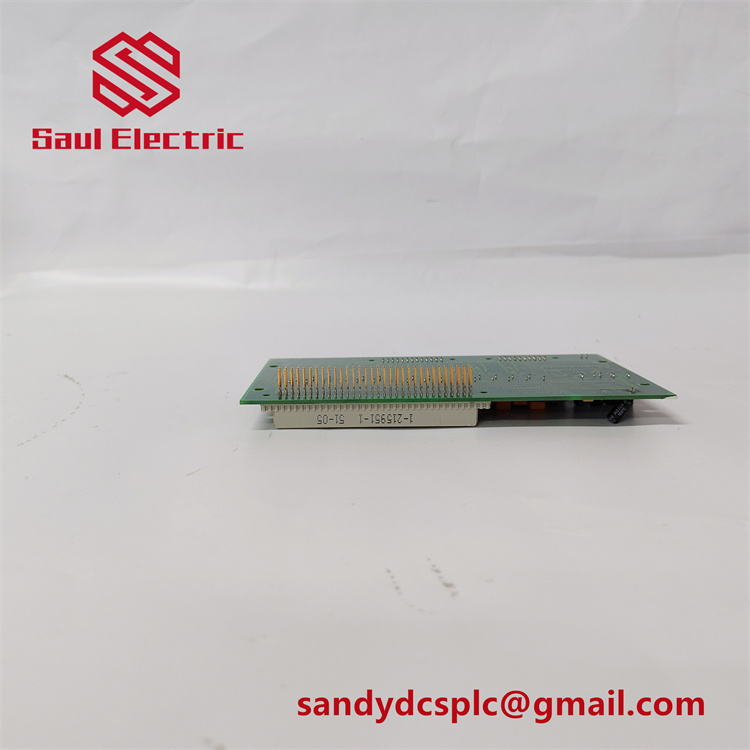

| Physical Dimensions | 120 x 80 x 23 mm (4.72” x 3.15” x 0.91”) |

| Weight | 0.45 kg (0.99 lbs) |

| Certifications | CE, UL, CSA |

| Motion Control Support | Up to 100 axes |

Main Features and Advantages

High Performance and Scalability: The ABB UAC326AE’s dual-core processor and modular design allow it to handle complex tasks while supporting future system expansions. Its 8 MB user memory and 100-axis motion control capability make it ideal for multi-axis robotic systems and high-speed manufacturing lines .

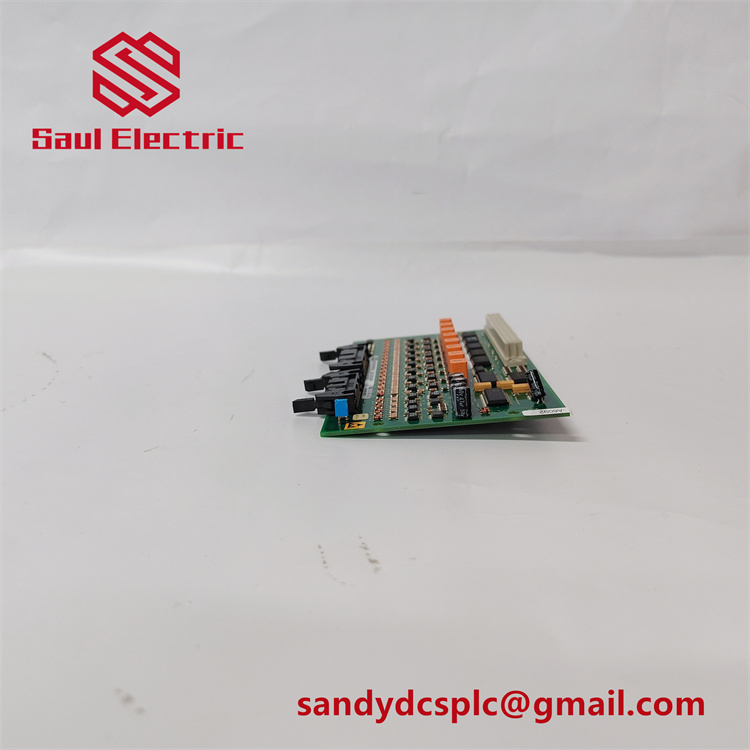

Advanced Signal Conditioning: Equipped with analog/digital I/O channels, the module supports real-time data acquisition from sensors and actuators, ensuring precise process monitoring. Its high-frequency PWM technology reduces power consumption and noise, enhancing energy efficiency in motor control applications .

Reliability and Safety: The module’s IP40-rated enclosure and wide temperature range ensure durability in challenging environments. Built-in diagnostics and redundant communication paths minimize downtime, while fail-safe mechanisms protect against overvoltage, undervoltage, and short circuits .

Flexible Integration: With support for multiple communication protocols, the ABB UAC326AE seamlessly integrates with ABB’s Industrial IT platform and third-party systems. This interoperability simplifies hybrid automation setups, enabling data-driven decision-making across the enterprise .

Ease of Maintenance: The hot-swappable design allows online replacement of faulty components without system shutdown. ABB’s intuitive programming tools and remote diagnostics further streamline maintenance workflows, reducing operational costs .

Application Areas

The ABB UAC326AE excels in diverse industrial sectors:

- Manufacturing: Controlling conveyor systems, robotic arms, and CNC machines in automotive and electronics production lines.

- Oil & Gas: Monitoring pipeline pressure, managing compressor stations, and implementing emergency shutdown systems (ESD).

- Power Generation: Optimizing turbine performance, regulating boiler combustion, and ensuring grid stability in renewable energy installations.

- Chemical Processing: Controlling reactor temperatures, managing hazardous material handling, and complying with ISO 14001 environmental standards.

- Pharmaceuticals: Maintaining sterile environments in cleanrooms, monitoring fermentation processes, and ensuring FDA-compliant batch records.

- Food & Beverage: Automating packaging lines, controlling pasteurization cycles, and managing inventory levels through IoT-integrated systems.

Related Products

- ABB AI 815: HART-compatible analog input module for precise sensor data acquisition, often paired with the UAC326AE in multi-parameter monitoring systems .

- ABB TU841: Termination unit for signal conditioning and isolation, enhancing the UAC326AE’s reliability in high-interference environments .

- ABB PM864AK01: High-performance controller module from ABB’s AC 800M series, suitable for large-scale process automation requiring advanced computational power.

- ABB PFVI401: Ethernet-APL module enabling seamless integration with field devices over long distances, complementing the UAC326AE in smart manufacturing setups.

- ABB HIEE300927R0101: Voltage/current control module for power systems, used alongside the UAC326AE in energy management applications.

Installation and Maintenance

Installation Preparation:

- Verify compatibility with ABB’s S800 I/O system and ensure proper grounding to prevent electromagnetic interference.

- Mount the module in a DIN rail enclosure within the specified temperature and humidity range.

- Connect power and communication cables using shielded wiring to maintain signal integrity.

Maintenance Recommendations:

- Regularly check diagnostic LEDs for operational status. A red fault indicator signals a module or communication failure, prompting immediate troubleshooting.

- Perform firmware updates quarterly to access the latest features and security patches.

- Clean the enclosure with a non-abrasive cloth to prevent dust accumulation, which can affect thermal performance. Replace worn-out cables or connectors as needed.

Product 保障

ABB guarantees the UAC326AE with a 1-year warranty covering defects in materials and workmanship. Our global technical support team provides 24/7 assistance for configuration, troubleshooting, and firmware updates. For mission-critical applications, optional extended warranties and priority service contracts are available to further reduce downtime. All modules undergo rigorous testing to meet ISO 9001 standards, ensuring consistent quality and reliability. With ABB, you gain a trusted partner for industrial automation, backed by decades of engineering expertise.

- HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com