Description

limitations.

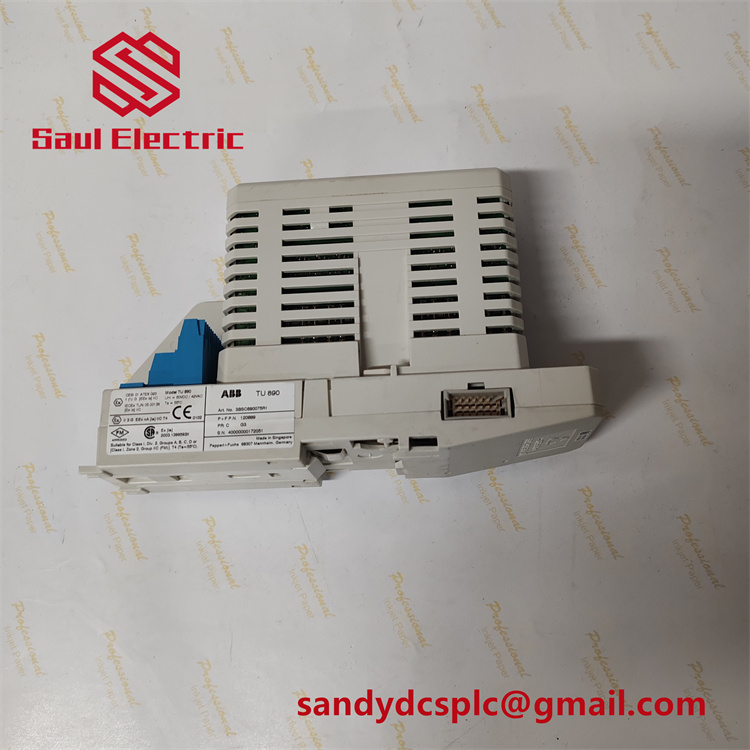

ABB TU890 3BSC690075R1 Module Termination Unit (MTU) with Intrinsic Safety Interface

Product Overview

The ABB TU890 3BSC690075R1 is a compact modular termination unit (MTU) designed for ABB’s S800 I/O system, serving as a critical interface between field devices and I/O modules in industrial automation. Optimized for intrinsically safe (IS) applications, it enables reliable connection and management of analog/digital signals while distributing the module bus to downstream MTUs and I/O modules. The TU890 is certified for ATEX/IECEx Zone 2 hazardous environments, making it ideal for industries such as oil & gas, chemical processing, and power generation where explosion-proof safety is paramount 23.

Key attributes include a rugged polycarbonate housing (IP20-rated), supporting DIN rail or panel mounting, and compatibility with a wide range of S800 I/O modules (e.g., AI 890, AO 895, DI 890). The TU890 plays a pivotal role in distributed control systems (DCS) like ABB’s Advant 800xA, ensuring seamless integration of sensors, actuators, and process equipment in hazardous areas 217.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB TU890 3BSC690075R1 |

| Manufacturer | ABB |

| Product Type | Module Termination Unit (MTU) with intrinsic safety interface |

| Function | Signal distribution hub for field devices and I/O modules in hazardous areas |

| Rated Voltage | 50 V AC/DC |

| Maximum Current | 2 A per I/O channel (limited by connected I/O module) |

| Operating Temperature | -25°C to +70°C (horizontal mounting) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5–95% non-condensing |

| Physical Dimensions | 194 mm (height) × 58.5 mm (width) × 64 mm (depth) |

| Weight | 0.3 kg (net) |

| Mounting Type | DIN rail or panel-mounted |

| Channels | 27 signal terminals (3×9) |

| Isolation Voltage | 50 V AC (dielectric test voltage) |

| Protection Class | IP20 |

| Certifications | ATEX/IECEx Zone 2, CE, UL, CSA, marine approvals (ABS, BV, DNV-GL) |

| Compatibility | S800 I/O modules (AI 890, AO 895, DI 890, DO 890, etc.) |

Key Features and Advantages

-

Intrinsic Safety Compliance:

The TU890 is ATEX/IECEx-certified for Zone 2 hazardous environments, ensuring safe operation in explosive atmospheres. It includes a wiring separator to isolate field signals from the module bus, preventing spark propagation 23. -

High-Density Signal Management:

- 27 Signal Terminals: Manages up to 27 field devices in a compact form factor (194 mm × 58.5 mm × 64 mm), reducing cabinet space requirements.

- Mechanical Keying: 6-position keys enable 36 configurations, preventing incorrect insertion of I/O modules and ensuring compatibility with specific signal types (e.g., analog vs. digital) 217.

-

Enhanced Environmental Resilience:

- Wide Temperature Range: Operates reliably from -25°C to +70°C, withstanding extreme conditions in offshore platforms or chemical plants.

- Robust Construction: IP20-rated housing and corrosion-resistant materials ensure durability in harsh industrial environments 317.

-

Tool-Free Installation:

Spring terminals enable fast, secure wiring without tools, reducing downtime during maintenance. The lightweight design (0.3 kg) simplifies installation in space-constrained cabinets 217. -

Multi-Industry Compatibility:

Supports seamless integration with ABB’s Advant 800xa DCS, AC500 PLCs, and third-party systems via Profibus DP or Ethernet/IP. It is widely used in oil & gas, water treatment, and manufacturing sectors requiring explosion-proof solutions 220.

Application Areas

The TU890 excels in industries requiring reliable high-channel density signal management and intrinsic safety compliance:

- Oil & Gas: Manages wellhead pressure sensors, valve actuators, and flow meters in offshore platforms and refineries.

- Chemical Processing: Controls reactor temperature transmitters, distillation column valves, and safety interlocks in hazardous zones.

- Power Generation: Integrates turbine control systems and boiler sensors in gas-fired power plants.

- Water Treatment: Manages pump stations and pH sensors in wastewater treatment plants with potentially explosive atmospheres 220.

Comparison with Related Models

| Model | Channels | Rated Voltage | Isolation Voltage | Key Applications |

|---|---|---|---|---|

| TU890 | 27 | 50 V AC/DC | 50 V AC | Intrinsically safe environments |

| TU842 | 16 | 50 V AC/DC | 500 V AC (test) | High-availability, redundant systems |

| TU847 | 16 | 24 V DC | 50 V AC | Redundant CI840/CI840A configurations |

| TU891 | 27 | 50 V AC/DC | 50 V AC | Non-intrinsic safety applications |

The TU890’s intrinsic safety certification and high-channel density distinguish it from the TU842/TU847 series, making it suitable for hazardous area applications where explosion-proof design is critical 211.

Installation and Maintenance

Installation Steps:

- Mounting: Secure the TU890 on a DIN rail in a dry, well-ventilated area.

- Wiring: Connect field wiring (24 V DC power and signal cables) using the spring terminals.

- Key Configuration: Adjust mechanical keys to match the connected I/O modules (e.g., AI 890 vs. DI 890) 217.

Maintenance Recommendations:

- Periodic Inspections: Check for loose connections or corrosion, especially in humid or corrosive environments.

- Firmware Updates: Ensure compatibility with the latest DCS software versions via ABB’s Automation Builder tool.

- Diagnostic Monitoring: Use ABB’s diagnostic tools to monitor signal integrity and module health 221.

Product Availability

- Warranty: 1 year against defects in materials and workmanship. Some distributors offer extended warranties (e.g., 2 years) 1718.

- Inventory: Limited stock available globally, with expedited delivery options (e.g., 3–5 days for Xiamen, China-based orders) 617.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com