Description

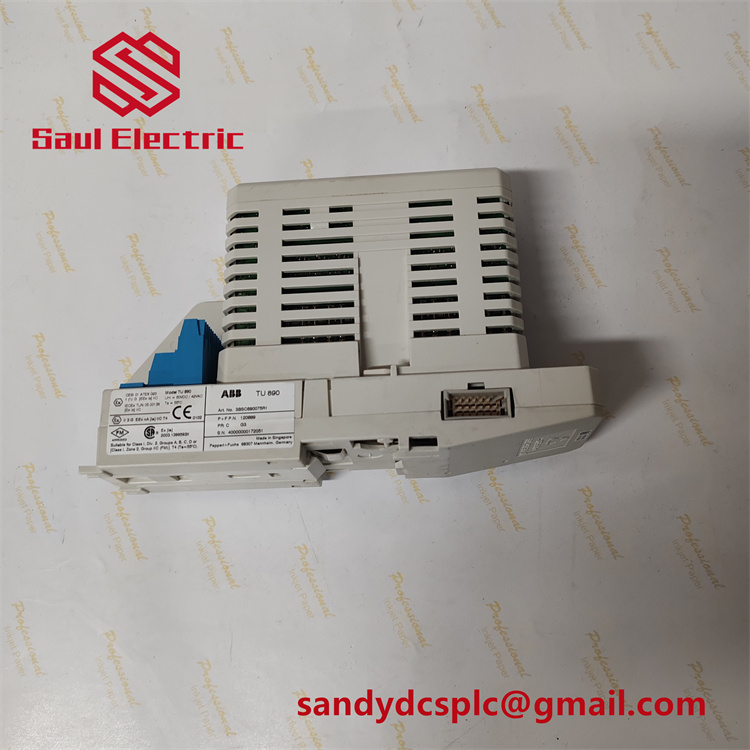

ABB TU811 Compact Module Termination Unit (MTU)

Product Overview

The ABB TU811 is a 8-channel compact module termination unit (MTU) designed for ABB’s S800 I/O system, serving as a critical interface between field devices and I/O modules in industrial automation. As a passive signal distribution hub, it enables reliable connection and management of high-voltage analog/digital signals while distributing the module bus to downstream MTUs and I/O modules. The TU811 is optimized for 250 V applications and offers enhanced isolation compared to standard MTUs, making it suitable for industries requiring robust signal integrity in harsh environments .

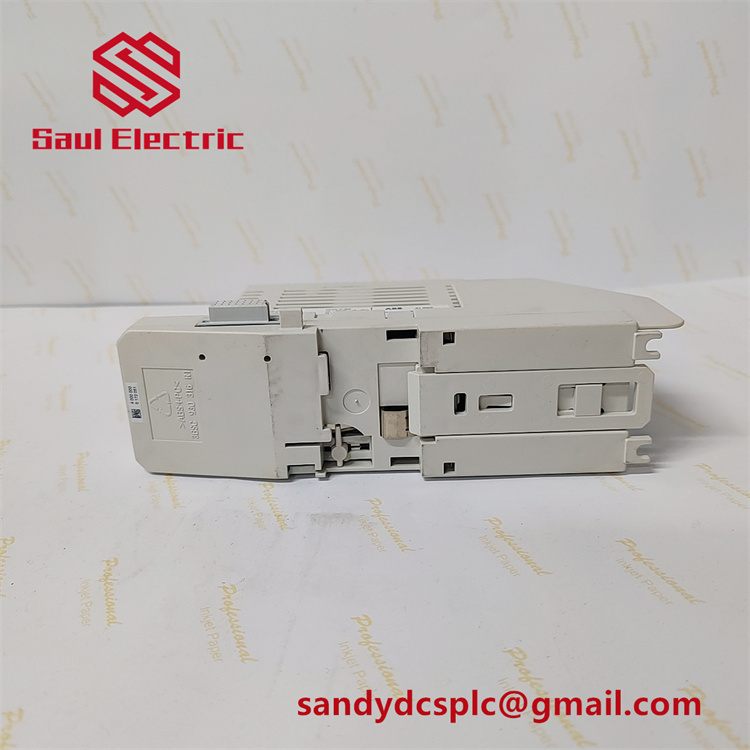

Key attributes include a rugged polycarbonate housing (IP20-rated), supporting DIN rail or panel mounting, and compatibility with a wide range of S800 I/O modules (e.g., DI 820, DO 821). The TU811 plays a pivotal role in distributed control systems (DCS) like ABB’s Advant 800xA, ensuring seamless integration of sensors, actuators, and process equipment across industries such as oil & gas, power generation, and chemical processing .

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB TU811 |

| Manufacturer | ABB |

| Product Type | Compact Module Termination Unit (MTU) for S800 I/O system |

| Function | Signal distribution hub for field devices and I/O modules |

| Rated Voltage | 250 V AC/DC |

| Maximum Current | 3 A per I/O channel; 5 A per process connection |

| Operating Temperature | 0°C to +55°C (horizontal mounting); 0°C to +40°C (vertical mounting) |

| Storage Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Physical Dimensions | 64 mm (depth) × 170 mm (height) × 58.5 mm (width) |

| Weight | 0.17 kg (net) |

| Mounting Type | DIN rail or panel-mounted |

| Channels | 8 channels (1×8 signal terminals) |

| Isolation Voltage | 2000 V AC |

| Protection Class | IP20 |

| Compatibility | S800 I/O modules (DI 820, DI 821, DO 820, DO 821, etc.) |

Key Features and Advantages

-

High-Voltage Signal Management:

The TU811 supports 250 V AC/DC signals, making it ideal for applications requiring robust isolation, such as high-power actuators or industrial machinery. Its 2000 V AC isolation voltage ensures signal integrity and safety in electrically noisy environments . -

Modular Signal Distribution:

- Mechanical Keying: Two 6-position keys enable 36 configurations, preventing incorrect insertion of I/O modules and ensuring compatibility with specific signal types (e.g., digital input/output) .

- Passive Bus Distribution: Distributes the module bus to downstream MTUs and generates addresses for I/O modules via signal shifting, simplifying system expansion .

-

Enhanced Environmental Resilience:

- Temperature Range: Operates reliably from 0°C to +55°C (horizontal) or 0°C to +40°C (vertical), withstanding extreme conditions in offshore platforms or power plants .

- Certifications: CE, UL, CSA, ATEX (Zone 2), and marine approvals (ABS, BV, DNV-GL) ensure compliance with global safety standards .

-

Tool-Free Installation:

Spring terminals enable fast, secure wiring without tools, reducing downtime during maintenance. The lightweight design (0.17 kg) and compact form factor simplify installation in space-constrained cabinets . -

Multi-Industry Compatibility:

Supports seamless integration with ABB’s Advant 800xa DCS, AC500 PLCs, and third-party systems via Profibus DP or Ethernet/IP. It is widely used in oil & gas, water treatment, and manufacturing sectors .

Application Areas

The TU811 excels in industries requiring reliable high-voltage signal management and modular I/O connectivity:

- Oil & Gas: Manages wellhead pressure sensors, valve actuators, and flow meters in offshore platforms and refineries.

- Power Generation: Integrates turbine control systems, boiler sensors, and grid stabilization equipment.

- Chemical Processing: Controls reactor temperature transmitters, distillation column valves, and safety interlocks.

- Water Treatment: Manages pump stations, pH sensors, and anaerobic digesters in wastewater treatment plants.

- Manufacturing: Connects robotic arm sensors, conveyor belt actuators, and quality control equipment in automotive production lines .

Comparison with Related Models

| Model | Channels | Rated Voltage | Isolation Voltage | Key Applications |

|---|---|---|---|---|

| TU811 | 8 | 250 V AC/DC | 2000 V AC | High-voltage industrial environments |

| TU810 | 16 | 50 V AC/DC | 50 V AC | General-purpose I/O distribution |

| TU810V1 | 16 | 50 V AC/DC | 50 V AC | Extended temperature ranges |

The TU811’s higher voltage rating and enhanced isolation distinguish it from the TU810 series, making it suitable for applications where safety and signal integrity are critical.

Installation and Maintenance

Installation Steps:

- Mounting: Secure the TU811 on a DIN rail in a dry, well-ventilated area.

- Wiring: Connect field wiring (24 V DC power and signal cables) using the spring terminals.

- Key Configuration: Adjust mechanical keys to match the connected I/O modules (e.g., DI 820 vs. DO 821) .

Maintenance Recommendations:

- Periodic Inspections: Check for loose connections or corrosion, especially in humid or corrosive environments.

- Firmware Updates: Ensure compatibility with the latest DCS software versions via ABB’s Automation Builder tool.

- Diagnostic Monitoring: Use ABB’s diagnostic tools to monitor signal integrity and module health .

Product Availability

- Warranty: 1 year against defects in materials and workmanship. Some distributors offer extended warranties (e.g., 2 years) .

- Inventory: Limited stock available globally, with expedited delivery options (e.g., 3–5 days for Xiamen, China-based orders) .

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com