Description

ABB TU804-1 Programmable Controller Module

Product Overview

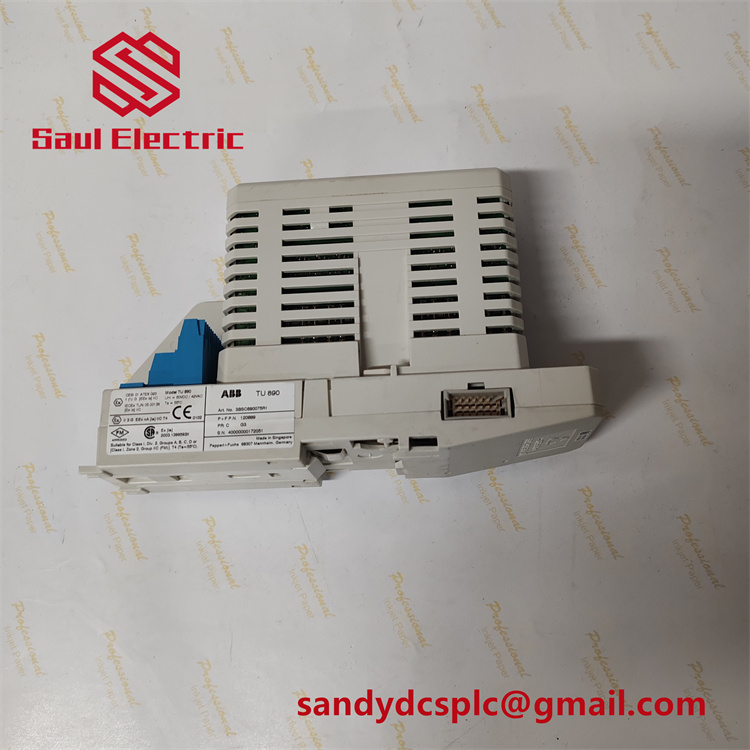

The ABB TU804-1 is a high-performance programmable logic controller (PLC) module designed for industrial automation applications, offering robust control capabilities and versatile connectivity. Unlike ABB’s I/O terminal units (e.g., TU515, TU715F), the TU804-1 serves as a core controller for managing complex processes, robotics, and machine automation systems. It features a compact design (64 mm × 186.5 mm × 131 mm) and lightweight construction (0.6 kg), making it suitable for space-constrained environments. The module operates on 24 V DC power and supports 8-channel I/O for integrating sensors, actuators, and other field devices.

Key attributes include a high-performance processor and large-capacity memory, enabling real-time data processing and multitasking. It is equipped with multiple communication interfaces, allowing seamless integration with industrial networks like Profibus, Modbus, and Ethernet/IP 216. This makes the TU804-1 ideal for applications requiring centralized control, such as CNC machine tools, conveyor systems, and robotic automation.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB TU804-1 |

| Manufacturer | ABB |

| Product Type | Programmable Logic Controller (PLC) Module |

| Function | Core controller for industrial automation, robotics, and process control |

| Power Supply | 24 V DC ±10% |

| Operating Temperature | -10°C to +60°C |

| Physical Dimensions | 64 mm (depth) × 186.5 mm (height) × 131 mm (width) |

| Weight | 0.6 kg |

| Mounting Type | DIN rail or panel-mounted |

| Communication Protocols | Profibus, Modbus, Ethernet/IP (compatible with ABB’s S500 I/O bus) |

| I/O Channels | 8 channels (digital/analog configurable) |

| Processor | High-performance CPU (specific model not disclosed in public sources) |

| Memory | Large-capacity RAM for program storage and data processing |

Key Features and Advantages

-

Modular Control Architecture:

The TU804-1 acts as a central controller for ABB’s distributed control systems, supporting integration with S500 I/O modules (e.g., AI 810, DI 610) and AC500 PLCs. Its modular design allows scalable system expansion for both simple and complex automation setups. -

Reliable Performance:

- Environmental Resilience: Withstands extreme temperatures (-10°C to +60°C) and mechanical stress, making it suitable for harsh industrial environments like manufacturing plants and chemical facilities.

- Redundancy Options: Supports redundant communication paths (e.g., dual Profibus DP ports) for high-availability applications, minimizing downtime.

-

Advanced Diagnostics:

Built-in self-diagnostics monitor power supply stability, communication status, and module health. Faults are categorized according to industrial standards (e.g., NAMUR NE 107), enabling proactive maintenance 2. -

Flexible Connectivity:

- Multi-Protocol Support: Native compatibility with Profibus, Modbus, and Ethernet/IP ensures seamless integration with third-party devices and ABB’s ecosystem.

- Fieldbus Integration: Directly interfaces with ABB’s S500 I/O bus, simplifying wiring and reducing hardware complexity.

-

Energy Efficiency:

The 24 V DC power supply design consumes minimal energy, making it suitable for remote locations with limited power infrastructure.

Application Areas

The TU804-1 excels in industries requiring reliable centralized control:

- Manufacturing: Controls robotic arms, conveyor systems, and quality control equipment in automotive and electronics production lines.

- Process Automation: Manages valves, pumps, and sensors in chemical reactors, oil refineries, and water treatment plants.

- Machine Tools: Provides precise motion control for CNC machines, ensuring accuracy in metal cutting and forming processes.

- Robotics: Integrates with ABB’s robot controllers (e.g., IRC5) for tasks like pick-and-place operations and welding 9.

- Energy Management: Monitors smart meters and relays in power distribution systems, enabling grid stabilization.

Related Products

- ABB AC500 PLC: A programmable logic controller that interfaces with the TU804-1 for advanced automation tasks.

- ABB S500 I/O Modules: Complementary modules (e.g., AI 810, DI 610) that expand the TU804-1’s I/O capabilities.

- ABB TU515: An I/O terminal unit for basic analog/digital applications, often used alongside the TU804-1 in modular systems.

- ABB CI871K01: A Profibus DP communication module for enhanced connectivity in distributed control systems.

Installation and Maintenance

Installation Preparation:

- Mount the TU804-1 on a DIN rail in a dry, well-ventilated area.

- Connect power (24 V DC) and fieldbus cables (e.g., Profibus DP) using the terminal blocks.

- Configure I/O channels and communication parameters via ABB’s Automation Builder software or local HMI.

Maintenance Recommendations:

- Calibration: Periodically calibrate connected I/O modules to ensure accuracy.

- Firmware Updates: Regularly update firmware to access new features and security patches.

- Environmental Checks: Inspect the housing for physical damage or corrosion, particularly in harsh environments.

- Diagnostic Monitoring: Use ABB’s diagnostic tools to monitor communication status and power supply stability.

Product Guarantee

ABB guarantees the TU804-1 against defects in materials and workmanship for 1 year 21. Our global technical support team provides 24/7 assistance for installation, troubleshooting, and system integration. In the event of a failure, expedited replacement services are available to minimize downtime. All units undergo rigorous testing to meet industrial standards, reflecting our commitment to delivering mission-critical solutions.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com