Description

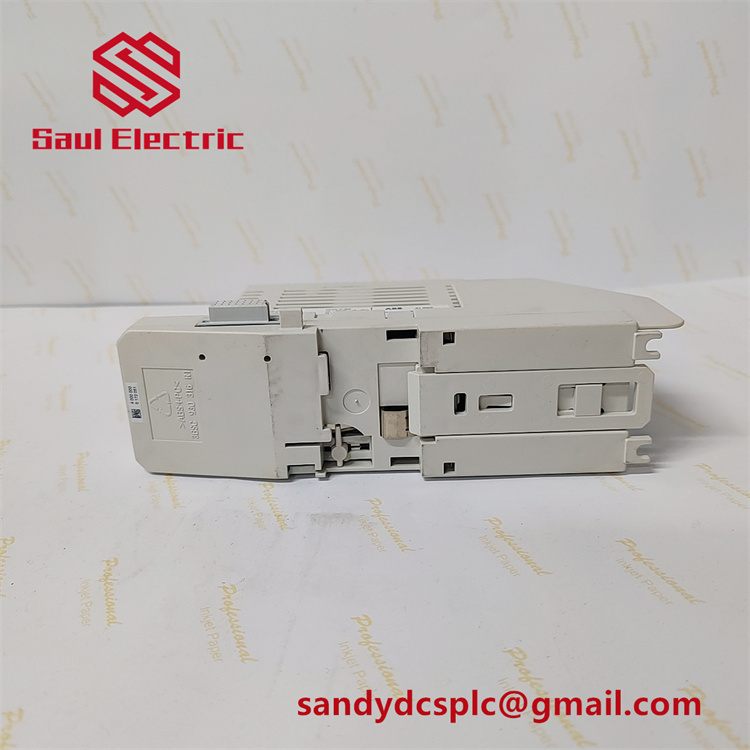

ABB TU715F 3BDH000378R0001 I/O Terminal Unit

Product Overview

The ABB TU715F 3BDH000378R0001 is a high-performance I/O terminal unit designed for ABB’s Advant 800xa distributed control system (DCS), enabling seamless integration of field devices with industrial automation platforms. Engineered for reliability in harsh environments, this module supports analog and digital I/O modules, redundant communication paths, and hot-swappable functionality, making it ideal for critical applications in oil & gas, power generation, and chemical processing. With a rugged polycarbonate housing (IP21-rated), the TU715F withstands extreme temperatures (-40°C to +70°C) and provides robust connectivity for real-time process control.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB TU715F 3BDH000378R0001 |

| Manufacturer | ABB |

| Product Type | I/O Terminal Unit (ITU) for Advant 800xa DCS |

| Function | Supports analog/digital I/O modules, Profibus DP communication |

| Power Supply | 24 V DC ±10% (nominal) |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -55°C to +85°C |

| Humidity | 5–95% non-condensing |

| Physical Dimensions | 90 mm (height) × 60 mm (width) × 60 mm (depth) |

| Weight | 0.2 kg |

| Mounting Type | DIN rail or panel-mounted |

| Communication Protocols | Profibus DP V0/V1 |

| Protection Class | IP21 |

| Redundancy | Redundant communication paths for high availability |

Key Features and Advantages

-

Modular I/O Expansion:

The TU715F acts as a foundational building block for Advant 800xa systems, supporting a wide range of analog and digital I/O modules (e.g., AI, AO, DI, DO). This modularity allows flexible configuration for both simple and complex automation setups, reducing hardware costs through shared infrastructure. -

High Reliability:

- Redundant Communication: Dual Profibus DP ports ensure continuous operation even if one communication path fails, critical for high-availability applications like turbine control in power plants.

- Hot-Swap Capability: I/O modules can be replaced without powering down the system, minimizing downtime during maintenance.

- Environmental Resilience: Withstands extreme temperatures (-40°C to +70°C) and mechanical stress, making it suitable for offshore platforms and petrochemical facilities.

-

Advanced Diagnostics:

Built-in self-diagnostics monitor power supply stability, communication status, and module health. Faults are categorized according to NAMUR NE 107 standards, enabling proactive maintenance and reducing unplanned downtime. -

Seamless Integration:

Native support for Profibus DP ensures compatibility with ABB’s S500 I/O modules and other third-party devices. It integrates seamlessly with Advant 800xa controllers, enabling real-time data exchange and centralized system management. -

Energy Efficiency:

The 24 V DC power supply design consumes minimal energy, making it suitable for remote locations with limited power infrastructure.

Application Areas

The TU715F excels in industries requiring reliable I/O connectivity and modular control systems:

- Oil & Gas: Monitors wellhead pressures, manages valve actuators, and controls pipeline flow in offshore and onshore facilities.

- Power Generation: Integrates sensors and actuators in turbine control systems, boiler management, and grid stabilization.

- Chemical Processing: Controls reactor temperatures, distillation columns, and safety interlocks in polymerization plants.

- Water Treatment: Manages pump stations, pH sensors, and anaerobic digesters in wastewater treatment facilities.

Related Products

- ABB TU515: A compact I/O terminal unit for basic analog/digital applications, with a narrower temperature range (0°C to +60°C) and IP20 protection.

- ABB TU716: Features spring terminals for tool-free wiring, ideal for fast installation in dynamic industrial environments.

- ABB CI871K01: A Profibus DP communication module for seamless integration with the TU715F in distributed control systems.

- ABB AC500 PLC: A programmable logic controller that interfaces with the TU715F for advanced automation tasks.

Installation and Maintenance

Installation Preparation:

- Mount the TU715F on a DIN rail in a dry, well-ventilated area.

- Connect power (24 V DC) and Profibus DP cables using the terminal blocks.

- Configure I/O modules via ABB’s Field Information Manager (FIM) software or local DCS interface.

Maintenance Recommendations:

- Calibration: Perform periodic calibration of connected I/O modules to ensure accuracy.

- Firmware Updates: Regularly update firmware to access new features and security patches.

- Environmental Checks: Inspect the housing for physical damage or corrosion, particularly in harsh environments.

- Diagnostic Monitoring: Use ABB’s diagnostic tools to monitor communication status and power supply stability.

Product Guarantee

ABB guarantees the TU715F 3BDH000378R0001 against defects in materials and workmanship for 1 year. Our global technical support team provides 24/7 assistance for installation, troubleshooting, and system integration. In the event of a failure, we offer expedited replacement services to minimize downtime. All units undergo rigorous testing to meet industrial standards, reflecting our commitment to delivering mission-critical solutions.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com