Description

Product Overview

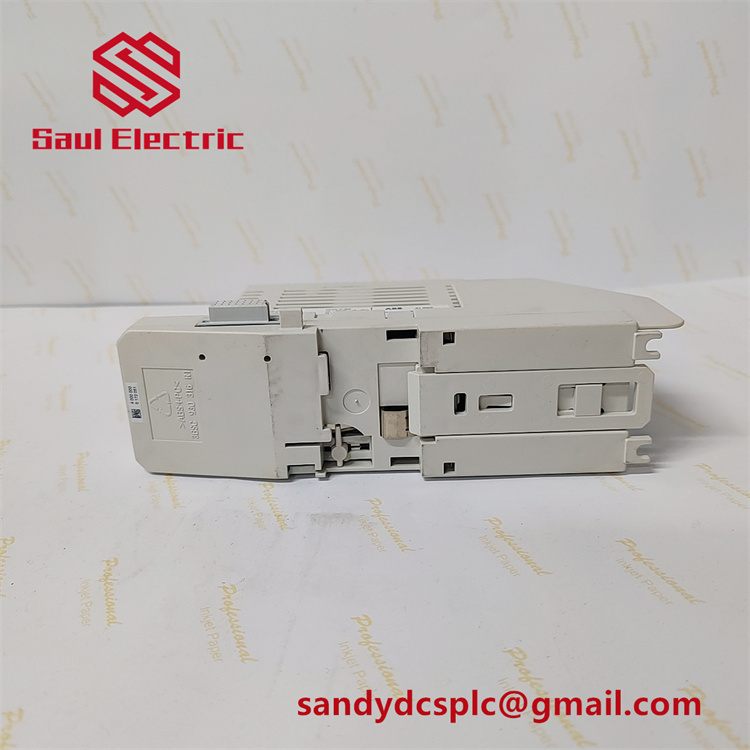

The ABB TU515 is a high-reliability I/O terminal unit designed for industrial automation systems, specifically tailored for ABB’s S500 distributed control platform. As a critical component in modular I/O architectures, the TU515 serves as the interface between field devices (e.g., sensors, actuators) and control systems, enabling seamless integration of analog and 24V DC digital modules. Constructed with a robust polycarbonate housing, this terminal unit supports screw-terminal connections, ensuring secure and vibration-resistant wiring in harsh industrial environments.

The TU515 features a compact design (67.5 mm × 135 mm × 28 mm) and lightweight construction (0.232 kg), making it ideal for space-constrained control cabinets. It operates within a wide temperature range (0°C to +60°C) and offers IP20 protection against solid particles, ensuring consistent performance in challenging conditions. By providing a standardized interface for ABB’s S500 I/O modules, the TU515 simplifies system expansion and maintenance, reducing downtime and operational costs. Its compatibility with both analog and digital signals makes it a versatile solution for process control, manufacturing, and energy management applications.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB TU515 |

| Manufacturer | ABB |

| Product Type | I/O Terminal Unit |

| Function | Supports analog and 24V DC digital modules with screw terminals |

| Supply Voltage | 24 V DC ±10% |

| Protection Class | IP20 |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +70°C |

| Physical Dimensions | 67.5 mm (width) × 135 mm (height) × 28 mm (depth) |

| Weight | 0.232 kg |

| Mounting Type | DIN rail or panel-mounted |

| Terminal Type | Screw terminals |

| I/O Bus Compatibility | ABB S500 I/O bus (10-pin male/female connectors) |

| Process Voltage Terminals | 24 V DC (UP) and 0 V DC (ZP) |

Main Features and Advantages

Modular I/O Integration: The TU515 acts as a foundational building block for ABB’s S500 I/O system, allowing seamless integration of analog and digital modules. This modularity enables flexible system design, supporting both simple and complex automation setups.

Rugged Construction: With an IP20-rated housing and robust screw terminals, the TU515 withstands mechanical stress, dust, and temperature fluctuations, ensuring long-term reliability in industrial settings.

Easy Installation: The compact DIN rail-mountable design simplifies installation, while the screw terminals facilitate secure wiring connections. The unit’s standardized I/O bus interface ensures plug-and-play compatibility with ABB’s S500 modules.

Power Management: The TU515 provides isolated process voltage terminals (24 V DC UP and 0 V DC ZP), enabling independent power supply for field devices and reducing electromagnetic interference.

Cost-Effective Expansion: By supporting multiple I/O modules, the TU515 minimizes the need for dedicated control cabinets, lowering hardware and installation costs. Its compatibility with ABB’s ecosystem ensures scalability for future upgrades.

Application Areas

The ABB TU515 is widely used in industries requiring reliable I/O connectivity and modular control systems:

- Manufacturing: Integrates sensors and actuators in production lines, supporting real-time monitoring of conveyor systems, robotic arms, and quality control equipment.

- Process Automation: Manages analog signals from pressure/temperature transmitters and digital signals from valves and pumps in chemical, oil & gas, and water treatment plants.

- Energy Management: Connects smart meters, relays, and control devices in power distribution systems, enabling efficient energy monitoring and grid stabilization.

- Building Automation: Integrates HVAC systems, lighting controls, and security sensors in commercial buildings, enhancing operational efficiency and occupant comfort.

- Machine Tools: Provides reliable I/O connections for CNC machines, ensuring precise control of cutting tools and workpiece positioning.

Related Products

- ABB TU516: A variant of the TU515 with spring terminals, offering tool-free wiring for faster installation.

- ABB TU516-H: Features hot-swap capability, allowing module replacement without powering down the system, ideal for high-availability applications.

- ABB TU541: A compact I/O terminal unit with screw terminals, designed for extreme environmental conditions (e.g., high humidity, vibration).

- ABB TU542: Similar to TU541 but with spring terminals, combining ruggedness with ease of use.

- ABB S500 I/O Modules: Complementary modules (e.g., AI 810, DI 610) that plug into the TU515 to expand system functionality.

- ABB AC500 PLC: A programmable logic controller that interfaces with the TU515 for advanced automation tasks.

Installation and Maintenance

Installation Preparation:

Ensure the TU515 is mounted on a DIN rail in a dry, well-ventilated area. Verify the supply voltage (24 V DC) and connect the I/O bus cables to the adjacent terminal units or controller. Use a screwdriver to secure the terminal unit to the rail and tighten the screw terminals for field device connections.

Ensure the TU515 is mounted on a DIN rail in a dry, well-ventilated area. Verify the supply voltage (24 V DC) and connect the I/O bus cables to the adjacent terminal units or controller. Use a screwdriver to secure the terminal unit to the rail and tighten the screw terminals for field device connections.

Maintenance Recommendations:

- Visual Inspections: Regularly check for loose connections, physical damage, or corrosion, particularly in harsh environments.

- Cleaning: Dust and debris can affect performance; use a dry cloth to clean the housing and terminals.

- Firmware Updates: Periodically update the firmware of connected I/O modules to access new features and security patches.

- Troubleshooting: Use ABB’s diagnostic tools to monitor power supply stability and identify communication errors. Replace faulty terminals or modules as needed.

Product Guarantee

ABB guarantees the TU515 against defects in materials and workmanship for 1 year. Our global technical support team provides 24/7 assistance for installation guidance, troubleshooting, and system integration. In the event of a failure, we offer expedited replacement services to minimize downtime. All units undergo rigorous testing to meet industry standards, reflecting our commitment to delivering reliable, high-performance automation solutions.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com