Description

ABB TP857 3BSE030192R1 Baseplate for BC810

Product Overview

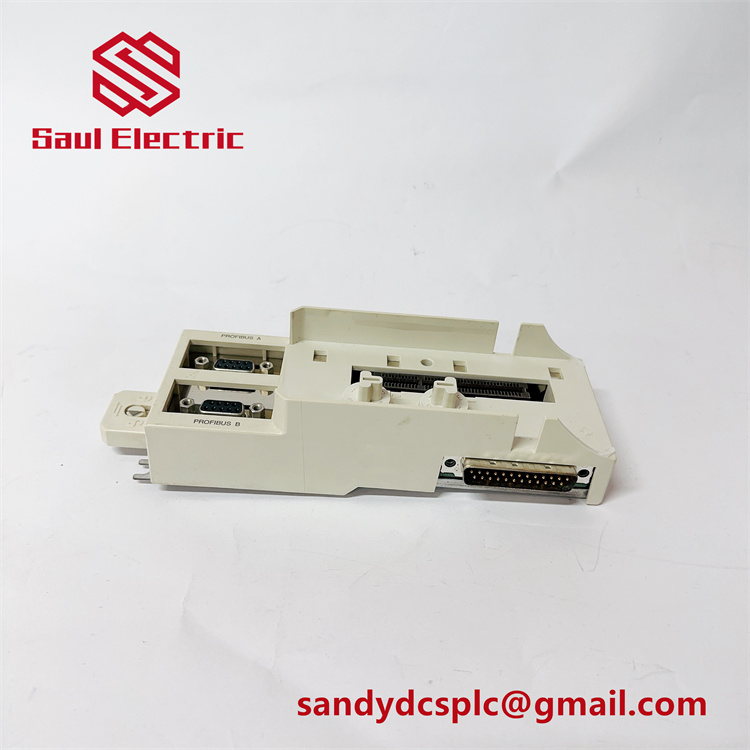

The ABB TP857 3BSE030192R1 is a high-reliability baseplate engineered for the BC810 controller system, a cornerstone of ABB’s industrial automation solutions. As the physical and electrical backbone of the BC810 unit, this baseplate provides a robust platform for mounting critical components like power supply modules, communication interfaces, and CPU boards, ensuring seamless integration within process control systems.

Designed with precision, the TP857 supports hot-swap functionality, enabling in-service replacement of modules without system downtime—a critical feature for industries requiring continuous operation, such as oil & gas, chemical manufacturing, and power generation. Its compact form factor (60mm width) and DIN rail mounting compatibility make it ideal for space-constrained environments, while the rugged construction withstands harsh industrial conditions, including high vibration and temperature fluctuations.

The TP857 facilitates connectivity through its CEX-Bus interface, which allows expansion of communication ports via dedicated interface units. This architecture enhances system flexibility by supporting redundant communication pathways and enabling integration with third-party devices. By ensuring stable power distribution and signal integrity, the TP857 reinforces the BC810 system’s ability to deliver mission-critical control in SIL 2/3-rated applications.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB TP857 3BSE030192R1 |

| Manufacturer | ABB |

| Product Type | Baseplate for BC810 Controller System |

| Power Supply | 24V DC (19.2–30V DC operating range) |

| Power Consumption | 50mA typical, 70mA max (for BC810 system) |

| Physical Dimensions | 60mm (width) x 185mm (height) x 127.5mm (depth) |

| Weight | 0.27 kg |

| Mounting Type | DIN rail or panel mount |

| Communication Interface | CEX-Bus for modular expansion |

| Safety Certifications | CE, UL 61010-1/2-201, Class 1 Div 2, ATEX/IECEx (via BC810 system) |

| Operating Temperature | +5°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Protection Class | IP20 |

Main Features and Advantages

Hot-Swap Capability: The TP857 supports online replacement of CPU boards and other modules, minimizing downtime during maintenance. This feature is critical for industries where continuous operation is non-negotiable, such as pharmaceuticals and nuclear power.

Modular Connectivity: The CEX-Bus interface allows seamless integration with communication modules (e.g., Profibus, Modbus) and redundant interfaces, enhancing system scalability. This flexibility enables the BC810 system to adapt to evolving automation requirements.

Rugged Design: Constructed with industrial-grade materials, the TP857 withstands extreme temperatures, humidity, and vibration, ensuring reliable performance in harsh environments like offshore platforms and chemical plants.

Space-Efficient Layout: With a width of 60mm, the baseplate optimizes cabinet space while providing robust mechanical support for heavy modules. Its compact design aligns with ABB’s commitment to reducing system footprint without compromising functionality.

High-Integrity Power Distribution: The baseplate incorporates voltage isolation and surge protection, ensuring stable power delivery to connected modules. This design mitigates risks of electrical interference and component damage.

Application Fields

The TP857 excels in industries where precision and reliability are paramount:

- Oil & Gas: Supports real-time monitoring and control of wellheads, pipelines, and refinery processes, ensuring compliance with safety standards.

- Chemical Processing: Enables seamless coordination of reactors, distillation units, and material handling systems, minimizing downtime during production cycles.

- Power Generation: Manages turbine control, grid stabilization, and energy distribution in power plants, leveraging its hot-swap capability for maintenance without disrupting supply.

- Water Treatment: Integrates with SCADA systems to monitor and optimize water purification processes, ensuring consistent quality and operational efficiency.

- Manufacturing: Facilitates automation in automotive assembly lines, food processing, and packaging, where modularity and scalability are key.

Related Products

- BC810K02: A complete controller kit including two TP857 baseplates, interconnection cables, and terminators, designed for redundant systems.

- PM865K01: A high-performance processor module compatible with the TP857, offering advanced logic control for complex automation tasks.

- TB850: CEX-Bus terminator for signal integrity, essential for extending communication segments in distributed control systems.

- TK851: Interconnection cable for linking BC810 units, ensuring reliable data transfer between baseplates.

- CI853K01: Communication interface module supporting Profibus DP and Ethernet/IP, expanding the TP857’s connectivity options.

Installation and Maintenance

Installation Preparation:

Ensure the TP857 is mounted on a DIN rail in a clean, dry environment with adequate ventilation. Verify power supply compatibility (24V DC) and proper grounding to prevent electromagnetic interference. Align the baseplate with the BC810 backplane connector and secure it using the provided brackets. Follow ABB’s wiring guidelines to connect field devices, ensuring polarity and voltage requirements are met.

Ensure the TP857 is mounted on a DIN rail in a clean, dry environment with adequate ventilation. Verify power supply compatibility (24V DC) and proper grounding to prevent electromagnetic interference. Align the baseplate with the BC810 backplane connector and secure it using the provided brackets. Follow ABB’s wiring guidelines to connect field devices, ensuring polarity and voltage requirements are met.

Maintenance Recommendations:

Regularly inspect the TP857 for loose connections, corrosion, or physical damage. Use ABB’s diagnostic tools to monitor power supply stability and module health. Perform periodic firmware updates to access the latest features and security patches. Replace worn-out components immediately, leveraging the baseplate’s hot-swap capability to minimize operational disruptions.

Regularly inspect the TP857 for loose connections, corrosion, or physical damage. Use ABB’s diagnostic tools to monitor power supply stability and module health. Perform periodic firmware updates to access the latest features and security patches. Replace worn-out components immediately, leveraging the baseplate’s hot-swap capability to minimize operational disruptions.

Product Guarantee

ABB guarantees the TP857 3BSE030192R1 against defects in materials and workmanship for 1 year. Our global technical support team provides 24/7 assistance for installation, troubleshooting, and system integration. In the unlikely event of a failure, we offer expedited replacement services to ensure minimal downtime. All modules undergo rigorous testing to meet international safety standards, reflecting our commitment to delivering mission-critical solutions that prioritize reliability and performance.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com