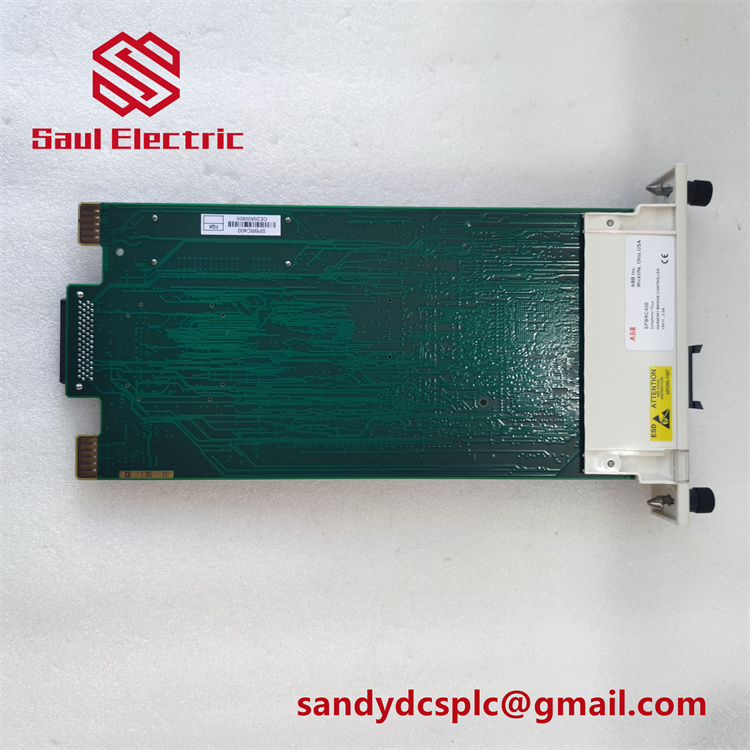

Description

ABB SPBRC300 Symphony Plus Bridge Controller

Product Overview

The ABB SPBRC300 is a high-performance bridge controller module designed for industrial automation systems, particularly within ABB’s Symphony Plus, Infi 90, and Harmony control platforms. Serving as a critical interface unit, it enables seamless integration of legacy and modern devices by converting communication protocols and facilitating real-time data exchange between distributed control systems (DCS), programmable logic controllers (PLCs), and intelligent electronic devices (IEDs). With support for multiple communication standards like Modbus TCP/IP, PROFINET, and EtherNet/IP, the SPBRC300 bridges protocol gaps in hybrid industrial setups, ensuring synchronized operation in power generation, oil refineries, and manufacturing plants.

Engineered for reliability, the SPBRC300 features a redundant design with dual power supplies and self-diagnostic capabilities, minimizing downtime in mission-critical applications. Its 32-bit RISC processor (MCF5407 CPU) delivers 257 MIPS of computational power, handling complex control algorithms and data processing tasks efficiently. The module’s rugged construction (IP20-rated) and wide temperature range (-40°C to +85°C) make it suitable for harsh environments, including offshore platforms and mining sites.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | SPBRC300 |

| Manufacturer | ABB |

| Product Type | Bridge Controller Module |

| Communication Protocols | Modbus TCP/IP, PROFINET, EtherNet/IP, RS-485, RS-232 |

| Interfaces | 2x Ethernet, 1x RS-485, 1x CAN |

| Processor | 32-bit RISC (MCF5407 CPU, 257 MIPS) |

| Memory | 1MB ROM, 8MB SDRAM, 512KB NVRAM, 2MB Flash |

| Power Supply | 24 V DC ±10% (default); select models support 380–480 V AC 36 |

| Redundancy | Hot-swappable dual power supplies |

| Operating Temperature | -40°C to +85°C |

| Physical Dimensions | 73.66 mm x 269.24 mm x 358.14 mm (L x W x H) 26 |

| Weight | 0.3–0.6 kg |

| Environmental Rating | IP20 |

| Certifications | CE, UL, IEC 61131-3, IEC 61508 (safety-related variants) 18 |

Key Features and Advantages

Protocol Conversion and Integration:

The SPBRC300 acts as a protocol translator, enabling interoperability between fiber-optic SPA buses, Ethernet networks, and legacy RS-485 systems. This eliminates compatibility barriers in hybrid automation setups, ensuring smooth data flow between protection relays (e.g., ABB REF542Plus) and modern SCADA platforms 17.

The SPBRC300 acts as a protocol translator, enabling interoperability between fiber-optic SPA buses, Ethernet networks, and legacy RS-485 systems. This eliminates compatibility barriers in hybrid automation setups, ensuring smooth data flow between protection relays (e.g., ABB REF542Plus) and modern SCADA platforms 17.

High-Performance Processing:

Equipped with a 32-bit RISC processor and large memory capacity, the SPBRC300 handles real-time data acquisition, complex control algorithms, and advanced analytics. It supports multiple programming languages (IEC 61131-3, Structured Text) for flexible configuration in batch, discrete, and continuous process control applications 218.

Equipped with a 32-bit RISC processor and large memory capacity, the SPBRC300 handles real-time data acquisition, complex control algorithms, and advanced analytics. It supports multiple programming languages (IEC 61131-3, Structured Text) for flexible configuration in batch, discrete, and continuous process control applications 218.

Redundancy and Fault Tolerance:

Dual power supplies and redundant communication channels ensure continuous operation during maintenance or component failure. Built-in self-diagnostic LED indicators and remote monitoring via ABB’s Relay Toolbox simplify troubleshooting and reduce downtime 618.

Dual power supplies and redundant communication channels ensure continuous operation during maintenance or component failure. Built-in self-diagnostic LED indicators and remote monitoring via ABB’s Relay Toolbox simplify troubleshooting and reduce downtime 618.

Rugged Industrial Design:

Rated for extreme temperatures and EMI/RFI protection, the SPBRC300 delivers consistent performance in harsh environments. Its DIN rail-mountable design and compact size facilitate easy integration into existing control cabinets 57.

Rated for extreme temperatures and EMI/RFI protection, the SPBRC300 delivers consistent performance in harsh environments. Its DIN rail-mountable design and compact size facilitate easy integration into existing control cabinets 57.

Safety Compliance:

Safety-related variants of the SPBRC300 comply with EN 61508 and EN ISO 13849 standards, making them suitable for critical applications requiring fail-safe operation, such as emergency shutdown systems in oil and gas facilities 18.

Safety-related variants of the SPBRC300 comply with EN 61508 and EN ISO 13849 standards, making them suitable for critical applications requiring fail-safe operation, such as emergency shutdown systems in oil and gas facilities 18.

Applications

The ABB SPBRC300 is widely deployed in industries requiring reliable integration of diverse control systems:

- Power Generation: Connects turbine control panels to substation automation networks, enabling remote monitoring of thermal, hydro, and nuclear power plants 29.

- Oil and Gas: Facilitates real-time data exchange between offshore platforms and onshore control centers, supporting wellhead control and pipeline management 717.

- Manufacturing: Integrates PLCs, DCS systems, and SCADA platforms in automotive assembly lines and food processing plants, ensuring synchronized production 118.

- Water/Wastewater: Optimizes treatment processes by bridging communication gaps between sensors, actuators, and control systems 79.

- Material Handling: Controls bridge cranes in ports and warehouses, offering programmable logic for precise load management and remote operation 1417.

Related Products

- ABB SPBRC410: High-speed bridge controller supporting IEC 61850 for smart grid applications.

- ABB Symphony Plus I/O Modules: Complementary modules (e.g., SPASI23 analog input, SPDSO14 digital output) for distributed control 1012.

- ABB 800xA Control System: Advanced DCS platform compatible with SPBRC300 for large-scale process automation.

- ABB SafePerformance Controllers: Safety-certified variants for fail-safe applications in hazardous environments 18.

- ABB S800 I/O System: Modular I/O platform for expanding control capabilities in industrial plants.

Installation and Maintenance

Installation Preparation:

Mount the SPBRC300 on a DIN rail in a dry, well-ventilated enclosure. Connect power cables (24 V DC or 380–480 V AC, depending on model) and communication interfaces using shielded twisted-pair cables. Configure protocols and parameters via ABB’s Symphony Plus engineering tools or third-party software like Siemens Step 7 56.

Mount the SPBRC300 on a DIN rail in a dry, well-ventilated enclosure. Connect power cables (24 V DC or 380–480 V AC, depending on model) and communication interfaces using shielded twisted-pair cables. Configure protocols and parameters via ABB’s Symphony Plus engineering tools or third-party software like Siemens Step 7 56.

Maintenance Recommendations:

- Routine Checks: Inspect LED indicators for status updates and verify cable connections quarterly.

- Firmware Updates: Regularly update firmware to access new features and security patches.

- Redundancy Testing: Conduct annual tests of dual power supplies and communication channels to ensure failover functionality.

- Environmental Cleaning: Dust the enclosure biannually to maintain thermal efficiency in high-dust environments 718.

Product Warranty and Support

The ABB SPBRC300 is backed by a 1-year warranty covering defects in materials and workmanship. ABB’s global support network provides 24/7 technical assistance, including remote diagnostics and firmware updates. Certified partners offer rapid replacement and repair services, ensuring minimal disruption to operations. All modules undergo rigorous testing to meet ISO 9001 and IEC standards, guaranteeing long-term reliability in critical applications 618.

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com