Description

ABB SPASI23 16-Channel High-Accuracy Analog Input Module

Product Overview

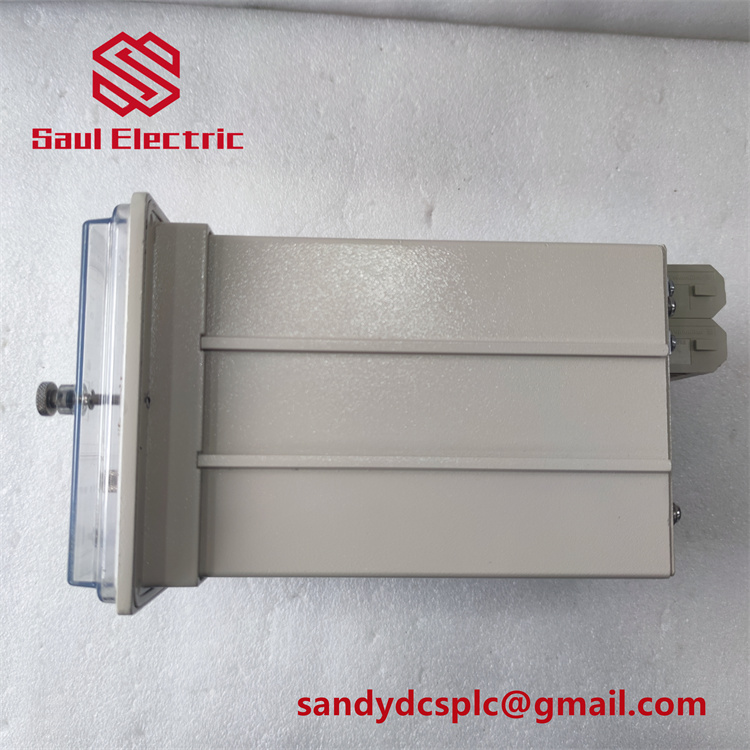

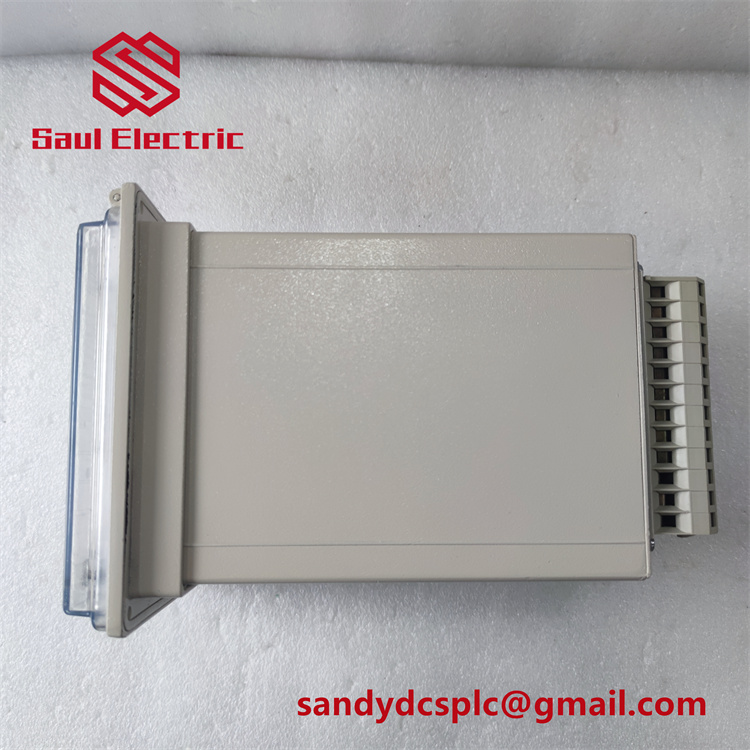

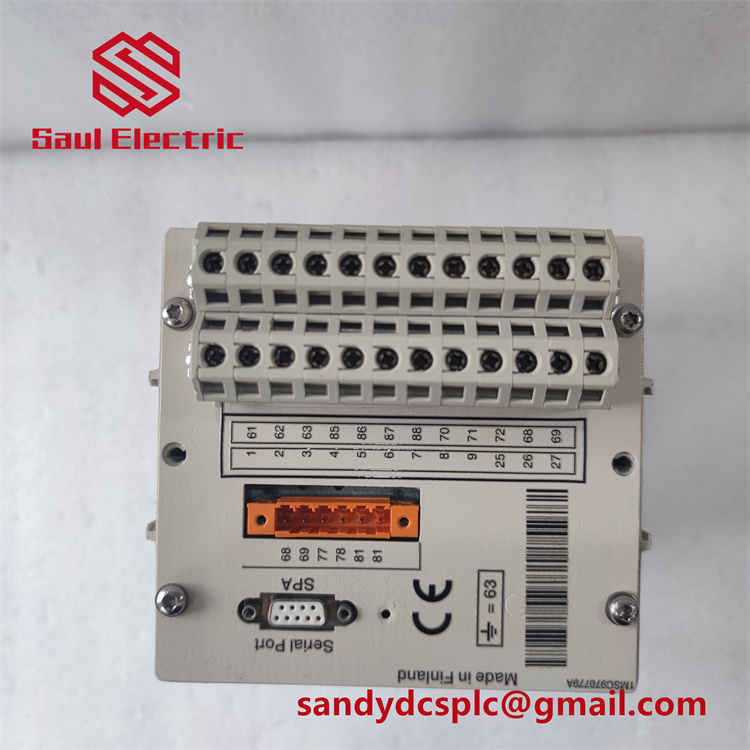

The ABB SPASI23 is a high-performance 16-channel analog input module designed for industrial automation systems, providing precise signal acquisition and processing for critical control applications. As part of ABB’s S800 I/O system, the ABB SPASI23 supports a wide range of input types, including thermocouples (TC), millivolts (mV), resistance temperature detectors (RTD), and high-level voltage/current signals, making it ideal for process control, energy management, and environmental monitoring910. Its compact design (73.66 mm x 360.68 mm x 269.24 mm) and robust construction ensure seamless integration into distributed control systems (DCS) and programmable logic controllers (PLC), even in harsh industrial environments with temperatures ranging from -20°C to +85°C29.

Engineered with a high-resolution ADC and 0.1% full-scale accuracy, the ABB SPASI23 delivers reliable measurement of signals such as temperature, pressure, and flow rate. Each channel supports configurable signal conditioning, including filtering and scaling, to optimize performance for specific applications. The module’s galvanic isolation (2500 V RMS) protects against electrical noise and ground faults, ensuring data integrity in noisy industrial settings910. With a fast conversion time of 250 µs per channel, it enables real-time monitoring and rapid control responses, critical for dynamic processes like power generation and manufacturing9.

The ABB SPASI23 features flexible communication options, including Modbus RTU and Profibus DP, allowing seamless integration with ABB’s AC800M controller and third-party systems215. Its DIN rail mounting and hot-swap capability simplify installation and maintenance, reducing downtime during module replacement. A self-diagnostic system continuously monitors internal components, providing early fault detection and detailed status reports via LED indicators or remote software1019.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | SPASI23 |

| Manufacturer | ABB |

| Product Type | 16-Channel Analog Input Module |

| Input Types | TC, mV, RTD, voltage (-10V to +10V), current (-20mA to +20mA) |

| Number of Channels | 16 |

| Accuracy | ±0.1% of full scale |

| Conversion Time | 250 µs per channel |

| Isolation | 2500 V RMS between inputs and system ground |

| Communication Interfaces | Modbus RTU, Profibus DP (optional) |

| Power Consumption | 2.5 W |

| Operating Temperature | -20°C to +85°C |

| Enclosure Rating | IP20 |

| Physical Dimensions | 73.66 mm x 360.68 mm x 269.24 mm |

| Weight | 0.771 kg |

| Safety Certification | CE, IEC 61131-2 |

Key Features and Advantages

Multi-Channel Signal Acquisition: The ABB SPASI23 supports 16 independent channels, each configurable for TC, mV, RTD, voltage, or current inputs, enabling simultaneous monitoring of diverse process parameters in complex systems910. This versatility reduces the need for multiple modules, simplifying system design and lowering costs.

High Precision and Speed: With 0.1% accuracy and a 250 µs conversion time, the module ensures precise real-time data capture, critical for applications like turbine temperature monitoring or chemical reactor control9. Its fast response time minimizes latency in closed-loop control systems.

Robust Environmental Performance: Rated for operation in extreme temperatures (-20°C to +85°C) and with EMI/RFI protection, the ABB SPASI23 excels in harsh environments such as oil refineries, mining sites, and offshore platforms29.

Flexible Integration: The module’s support for Modbus RTU and Profibus DP protocols allows seamless integration with ABB’s AC800M controller and third-party PLC/DCS systems, facilitating interoperability in hybrid automation setups215.

Easy Maintenance: Hot-swap capability and self-diagnostic features enable quick module replacement and proactive fault management, reducing downtime. The module’s DIN rail mounting and intuitive wiring terminals further streamline installation1019.

Applications

The ABB SPASI23 is widely deployed in industries requiring reliable analog signal acquisition:

- Process Control: Monitoring temperature, pressure, and flow in chemical plants, water treatment facilities, and pharmaceutical manufacturing lines.

- Energy Management: Collecting data from RTDs and thermocouples in power generation systems, including gas turbines and renewable energy inverters910.

- Environmental Monitoring: Capturing analog signals from sensors in air quality monitoring systems, wastewater treatment plants, and industrial emissions control systems.

- Machine Automation: Integrating with PLCs to control motor drives, robotics, and CNC machines, ensuring precise motion and process optimization.

- Building Automation: Managing HVAC systems by measuring room temperatures, humidity levels, and energy consumption in smart buildings110.

Related Products

- ABB SPASI24: Enhanced version with additional signal conditioning and higher channel density, suitable for large-scale process control.

- ABB SPASI25: Supports advanced diagnostics and predictive maintenance features, ideal for critical infrastructure applications.

- ABB S800 I/O System: Modular platform for distributed control, including power supplies, communication modules, and other I/O devices complementary to the ABB SPASI23.

- ABB AC800M Controller: High-performance controller optimized for integration with SPASI23 modules, offering real-time data processing and redundant control.

- ABB PROFIBUS DP/PA Coupler: Enables seamless communication between SPASI23 modules and PROFIBUS-based systems.

Installation and Maintenance

Installation Preparation:

Mount the ABB SPASI23 on a DIN rail in a dry, well-ventilated enclosure. Connect analog signals to the terminal block, ensuring proper grounding to minimize noise. Configure input types, scaling, and communication parameters using ABB’s Compact Control Builder software or third-party tools compatible with Modbus RTU/Profibus DP919. Verify power supply compatibility (24 V DC) and secure connections before powering up the system.

Mount the ABB SPASI23 on a DIN rail in a dry, well-ventilated enclosure. Connect analog signals to the terminal block, ensuring proper grounding to minimize noise. Configure input types, scaling, and communication parameters using ABB’s Compact Control Builder software or third-party tools compatible with Modbus RTU/Profibus DP919. Verify power supply compatibility (24 V DC) and secure connections before powering up the system.

Maintenance Recommendations:

Regularly inspect the module for loose connections or physical damage. Clean dust from the enclosure to maintain optimal thermal performance. Perform periodic calibration checks using a precision voltage/current source to ensure accuracy. Update firmware to the latest version to access new features and security patches. Replace faulty modules using hot-swap procedures to avoid system downtime1019.

Regularly inspect the module for loose connections or physical damage. Clean dust from the enclosure to maintain optimal thermal performance. Perform periodic calibration checks using a precision voltage/current source to ensure accuracy. Update firmware to the latest version to access new features and security patches. Replace faulty modules using hot-swap procedures to avoid system downtime1019.

Product Warranty and Support

The ABB SPASI23 is backed by a 1-year warranty covering defects in materials and workmanship. ABB’s global support network provides 24/7 technical assistance, including remote diagnostics and firmware updates. Certified partners offer rapid replacement and repair services, ensuring minimal disruption to operations. All modules undergo rigorous testing to meet ISO 9001 and IEC standards, guaranteeing long-term reliability in critical applications419.

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com