Description

Product Overview

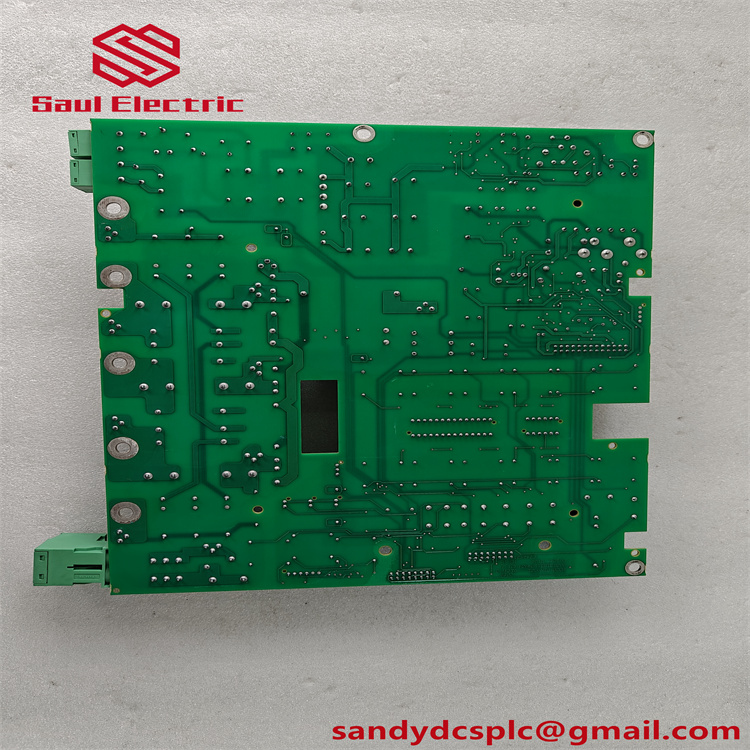

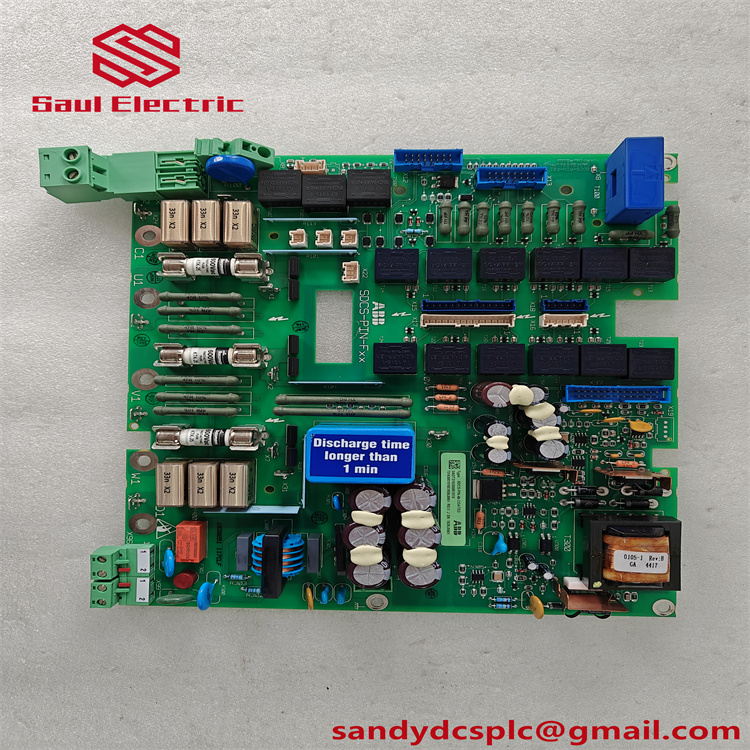

The ABB SDCS-PIN-4B is a high-precision pulse interface module designed for ABB’s SDCS (DC Drive Control System) series, specifically engineered to manage encoder feedback in DC motor control applications. As a critical component of the DCS800 DC drive platform, this module processes position and speed signals from incremental or absolute encoders, enabling precise motor control and dynamic system response. The SDCS-PIN-4B features the SDCS-PIN-4B interface, which supports up to four encoder channels with galvanic isolation, ensuring signal integrity in electrically noisy environments. It integrates seamlessly with ABB’s DC drive controllers, providing real-time feedback for closed-loop control systems in industrial automation setups.

Engineered for reliability, the SDCS-PIN-4B withstands harsh industrial conditions, including temperature fluctuations and vibration, making it ideal for heavy-duty applications. Its modular design allows easy integration into existing SDCS configurations, while built-in diagnostics monitor encoder health and signal quality to prevent unexpected downtime. By converting encoder pulses into standardized control signals, the SDCS-PIN-4B enhances the accuracy of motor speed and position control, contributing to improved productivity and energy efficiency in manufacturing processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB SDCS-PIN-4B |

| Manufacturer | ABB |

| Product Type | Pulse Interface Module (DC Drive Control) |

| Encoder Channels | 4 channels (incremental/absolute encoder support) |

| Input Voltage | 24 VDC ±10% |

| Signal Types | TTL/HTL compatible (5–30 VDC signal levels) |

| Maximum Frequency | 1 MHz (per channel) |

| Isolation | Galvanic isolation (500 VDC between channels) |

| Operating Temperature | -20°C to +60°C |

| Physical Dimensions | 170 x 100 x 50 mm (W x H x D) |

| Weight | 0.3 kg |

| Mounting Method | DIN rail or panel mounting |

| Certifications | CE, UL, CSA |

Key Features and Advantages

High-Precision Feedback Processing: The SDCS-PIN-4B ensures accurate motor control by converting encoder pulses into precise speed and position data, supporting up to 1 MHz signal frequency for high-speed applications. Its four independent channels allow simultaneous monitoring of multiple motors or redundant encoder setups.

Robust Signal Isolation: Galvanic isolation between channels and the system ground protects against voltage spikes and ground loops, maintaining signal integrity in industrial environments with high electromagnetic interference. This feature minimizes errors and reduces maintenance costs.

Flexible Encoder Compatibility: The module supports both incremental (e.g., TTL/HTL) and absolute encoders, adapting to diverse motor control requirements. It also offers configurable signal filtering to optimize performance for specific encoder types.

Easy Integration and Diagnostics: Designed for plug-and-play compatibility with ABB’s SDCS and DCS800 drives, the SDCS-PIN-4B simplifies system commissioning. Built-in LED indicators provide real-time diagnostics for power, communication, and encoder faults, enabling quick troubleshooting.

Rugged Industrial Design: With an operating temperature range of -20°C to +60°C and vibration resistance (up to 50 G), the SDCS-PIN-4B withstands harsh conditions in manufacturing, mining, and material handling applications, ensuring long-term reliability.

Applications

The ABB SDCS-PIN-4B excels in industrial sectors requiring precise DC motor control:

- Metallurgy: Controls rolling mills, furnaces, and conveyors in steel production, ensuring consistent material thickness and quality.

- Mining: Manages large hoists, crushers, and conveyor systems, enabling reliable operation in harsh underground and surface environments.

- Paper and Pulp: Synchronizes speed and tension in paper machines, reducing material waste and improving production efficiency.

- Textile Manufacturing: Drives spinning and weaving machines with high accuracy, ensuring uniform fabric quality.

- Marine Applications: Powers ship propulsion systems and winches, delivering reliable performance in maritime environments.

By providing real-time feedback for closed-loop control, the SDCS-PIN-4B optimizes motor performance, reduces energy consumption, and minimizes mechanical wear in critical applications.

Related Products

- ABB SDCS-CON-2A: Control board for SDCS drives, integrating with SDCS-PIN-4B for comprehensive motor control.

- ABB DCS800-S02: DC drive system compatible with SDCS-PIN-4B, offering high-power motor control for industrial applications.

- ABB SDCS-PIN-3A: Earlier-generation pulse interface module with similar functionality, suitable for legacy systems.

- ABB ENC-58: Incremental encoder designed for compatibility with SDCS-PIN-4B in speed and position control.

- ABB SDCS-FEX-2: Fieldbus extension module that works with SDCS-PIN-4B to enable communication with Profibus or Ethernet/IP networks.

Installation and Maintenance

Installation Preparation:

Ensure the control cabinet meets IP20 standards and is free of dust and moisture. Mount the SDCS-PIN-4B on a DIN rail using provided hardware, maintaining 25 mm clearance for heat dissipation. Connect 24 VDC power and encoder cables, ensuring shielded wiring to minimize interference. Configure encoder parameters (e.g., pulse count, signal type) via the drive’s programming interface.

Ensure the control cabinet meets IP20 standards and is free of dust and moisture. Mount the SDCS-PIN-4B on a DIN rail using provided hardware, maintaining 25 mm clearance for heat dissipation. Connect 24 VDC power and encoder cables, ensuring shielded wiring to minimize interference. Configure encoder parameters (e.g., pulse count, signal type) via the drive’s programming interface.

Maintenance Recommendations:

Regularly inspect the module for loose connections or physical damage, especially in vibrating environments. Clean dust from vents using a static-free cloth every six months. Monitor diagnostic LEDs for fault indicators—flashing red lights may signal encoder issues or power irregularities. Replace the module if self-tests fail, following ABB’s recommended procedures to maintain system reliability.

Regularly inspect the module for loose connections or physical damage, especially in vibrating environments. Clean dust from vents using a static-free cloth every six months. Monitor diagnostic LEDs for fault indicators—flashing red lights may signal encoder issues or power irregularities. Replace the module if self-tests fail, following ABB’s recommended procedures to maintain system reliability.

Product Warranty and Support

ABB guarantees the SDCS-PIN-4B against defects in materials and workmanship for 1 year from purchase. This warranty covers repair or replacement of faulty components, excluding damage from improper installation or environmental factors. Customers benefit from ABB’s global technical support network, including 24/7 assistance for troubleshooting and firmware updates. For mission-critical applications, ABB offers extended warranty plans and priority service to minimize downtime and optimize performance.

Product Information

- Brand Model: ABB SDCS-PIN-4B

- Product Name: Pulse Interface Module

- Warranty: 1 year

- Size: 170 x 100 x 50 mm

- Weight: 0.3 kg

- Origin: Sweden

- Inventory: Spot/Futures

- Delivery Time: Goods in stock will be dispatched within 3 days after payment

- Order Time: Goods will be dispatched within one month after payment

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com