Description

ABB SD822 3BSC610038R1: Advanced PROFINET/PROFIBUS DP Communication Module for Extreme Industrial Environments

Product Overview

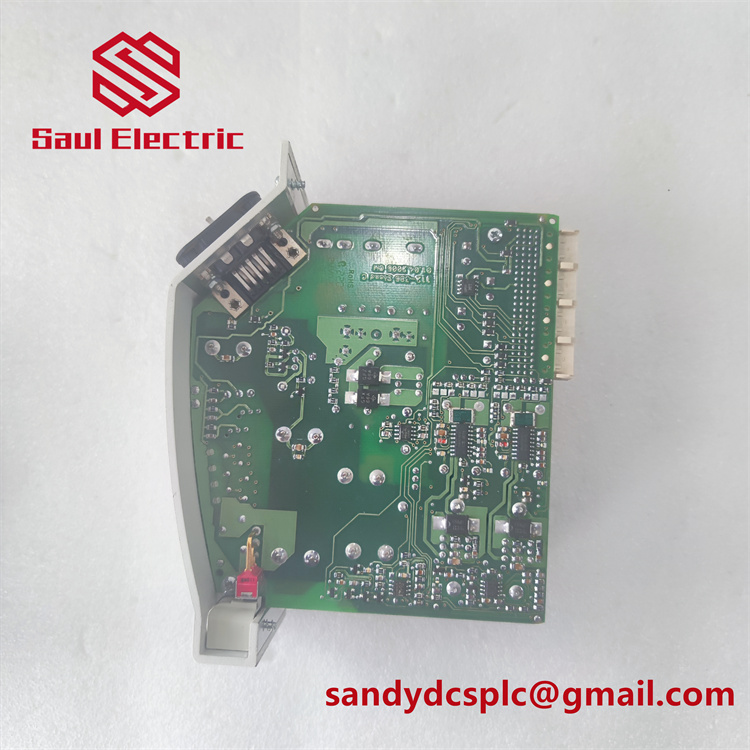

The ABB SD822 3BSC610038R1 is a next-generation dual-protocol communication module engineered for mission-critical industrial automation systems. As part of ABB’s AC800M modular control platform, this module supports PROFINET IO RT and PROFIBUS DP V1, enabling real-time integration of field devices (e.g., sensors, actuators) with centralized control systems. The SD822 3BSC610038R1 features dual-port redundancy, hot-swap capabilities, and an extended temperature range (-40°C to +85°C), making it ideal for harsh environments such as offshore oil platforms, mining operations, and extreme-temperature manufacturing facilities.

Equipped with a 32-bit ARM Cortex-M4 processor (400 MHz) and 64 MB RAM + 128 MB flash memory, the SD822 3BSC610038R1 delivers 20% faster data processing than previous models. Its multi-layer PCB design and 35% EMI shielding reduction ensure stable operation in high-noise environments, while ATEX certification allows deployment in hazardous areas. The module integrates seamlessly with ABB’s Advant OCS and Industrial IT systems, supporting OPC UA for cloud-based analytics and predictive maintenance.

Technical Specifications

| Parameter | Value |

|---|---|

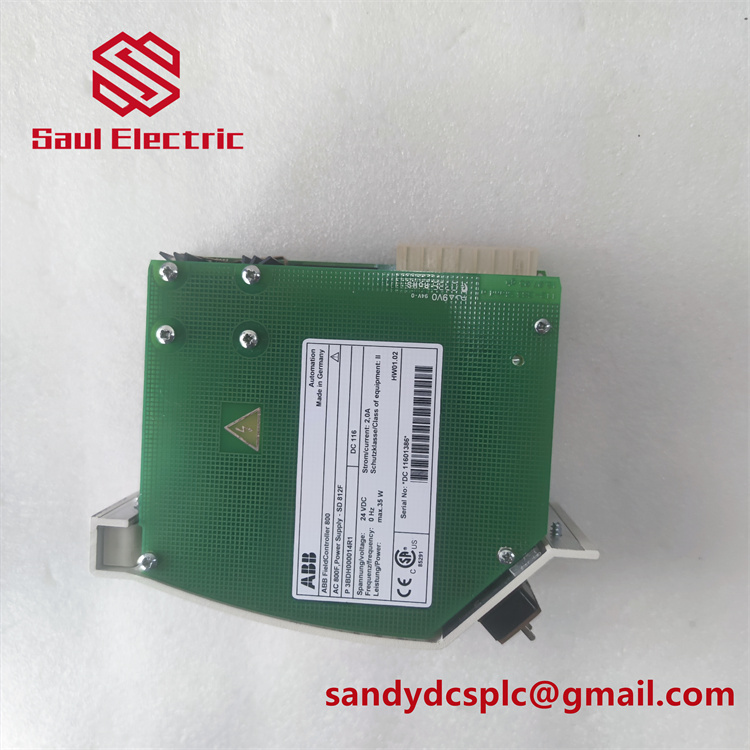

| Product Model | ABB SD822 3BSC610038R1 |

| Manufacturer | ABB |

| Product Type | PROFINET/PROFIBUS DP Communication Module (ATEX-certified) |

| Input Voltage | 24V DC (±15%) with redundant power inputs |

| Communication Protocols | PROFINET IO RT, PROFIBUS DP V1, Modbus RTU, OPC UA |

| Data Rate | 100 Mbps (PROFINET) / 12 Mbps (PROFIBUS DP) |

| Interfaces | 2 x RJ45 (PROFINET), 2 x 9-pin D-sub (PROFIBUS DP) |

| Processor | 32-bit ARM Cortex-M4 (400 MHz, 20% faster than SD821) |

| Memory | 64 MB RAM + 128 MB flash (expandable via S100 I/O bus) |

| Operating Temperature | -40°C to +85°C (ambient) |

| Enclosure Rating | IP20 (DIN rail-mounted with extended thermal tolerance) |

| Certifications | CE, UL 508, IEC 61131-2, RoHS, ATEX (Zone 2/22) |

| Physical Dimensions | 125mm x 100mm x 50mm |

| Weight | ~0.85kg |

| Mounting | DIN rail (EN 50022) with spring-loaded clips |

| MTBF | 200,000 hours (22.8 years) |

| EMI Shielding | Reduces interference by 35% (compared to 30% in SD821) |

Key Features and Advantages

Extreme Environment Capability:

The SD822 3BSC610038R1 is specifically designed for harsh conditions, with an extended temperature range (-40°C to +85°C) and ATEX certification for use in explosive atmospheres. Its ruggedized enclosure and enhanced thermal management ensure reliable operation in offshore platforms, mining equipment, and high-temperature processing plants.

The SD822 3BSC610038R1 is specifically designed for harsh conditions, with an extended temperature range (-40°C to +85°C) and ATEX certification for use in explosive atmospheres. Its ruggedized enclosure and enhanced thermal management ensure reliable operation in offshore platforms, mining equipment, and high-temperature processing plants.

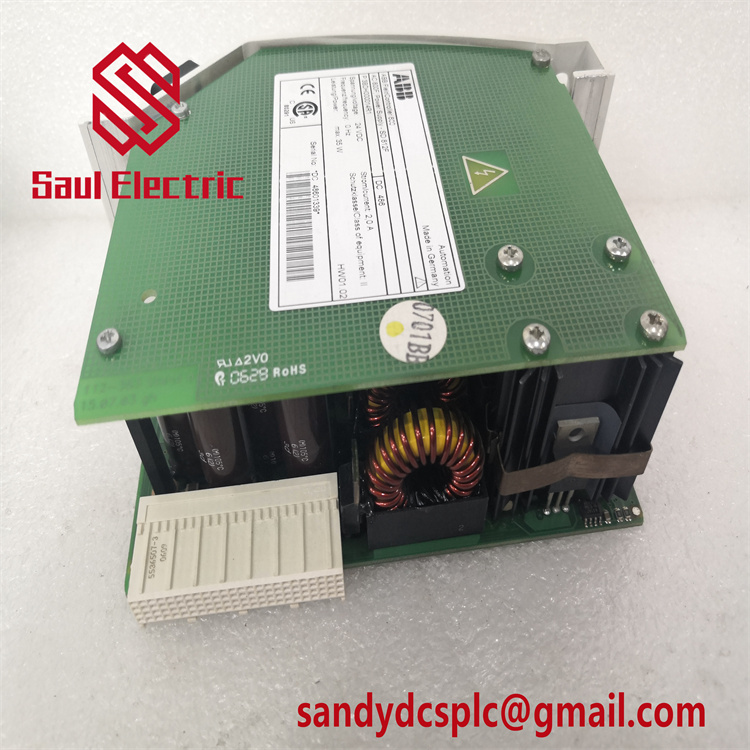

Enhanced Redundancy and Reliability:

Dual-port redundancy and hot-swap functionality minimize downtime, while redundant 24V DC inputs protect against power fluctuations. The 35% EMI shielding reduction (compared to SD821) ensures stable communication in electrically noisy environments, such as near large motors or welding equipment.

Dual-port redundancy and hot-swap functionality minimize downtime, while redundant 24V DC inputs protect against power fluctuations. The 35% EMI shielding reduction (compared to SD821) ensures stable communication in electrically noisy environments, such as near large motors or welding equipment.

High-Speed Data Handling:

With 100 Mbps PROFINET and 12 Mbps PROFIBUS DP capabilities, the module supports real-time control applications like robotics and precision manufacturing. The ARM Cortex-M4 processor enables low-latency data processing for time-sensitive operations, such as coordinating conveyor systems in automotive assembly lines.

With 100 Mbps PROFINET and 12 Mbps PROFIBUS DP capabilities, the module supports real-time control applications like robotics and precision manufacturing. The ARM Cortex-M4 processor enables low-latency data processing for time-sensitive operations, such as coordinating conveyor systems in automotive assembly lines.

Advanced Diagnostics:

Built-in LED indicators provide instant visibility into power status, communication activity, and fault conditions. The module also supports remote diagnostics via ABB’s Ability™ platform, allowing predictive maintenance to reduce mean time to repair (MTTR) by up to 40%.

Built-in LED indicators provide instant visibility into power status, communication activity, and fault conditions. The module also supports remote diagnostics via ABB’s Ability™ platform, allowing predictive maintenance to reduce mean time to repair (MTTR) by up to 40%.

Applications

The SD822 3BSC610038R1 excels in industries requiring robust communication solutions under extreme conditions:

- Offshore and Marine:

- Subsea control module (SCM) integration in oil platforms.

- Engine room monitoring in arctic-rated vessels.

- Mining and Metals:

- Real-time control of conveyor systems in underground mines.

- Remote diagnostics for heavy machinery in high-dust environments.

- Power Generation:

- Turbine control in geothermal power plants with high ambient temperatures.

- Grid-connected inverter management in solar farms exposed to wide temperature variations.

- Chemical Processing:

- Distributed I/O synchronization in hazardous material production facilities.

- Predictive maintenance of pumps and valves in ATEX-certified zones.

Related Products

- ABB SD821: Base variant for standard industrial environments (-25°C to +60°C).

- ABB SD803F: PROFINET-only module for Ethernet-centric systems.

- ABB CI535: PROFIBUS DP/Modbus RTU module for legacy system integration.

- ABB PM511MV08: PLC processor for unified control system architecture.

- ABB AC800M DCS: Modular control platform with redundant communication backplanes.

- ABB TB841 Terminal Blocks: Required for secure field wiring in extreme conditions.

- ABB Engineering Workplace: Configuration software supporting ATEX zone settings.

- ABB Ability™ Edge: Edge computing platform for real-time analytics in hazardous areas.

- ABB SD822-2: Variant with additional CANopen support.

- ABB Lifecycle Care Service: Extended warranty (up to 5 years) and proactive component replacement.

Installation and Maintenance

Installation Preparation:

Mount the SD822 3BSC610038R1 on a DIN rail with 30mm clearance for thermal expansion. Connect dual redundant 24V DC inputs using ABB’s TB841 terminal blocks (1.5 N·m torque). Configure communication parameters via ABB’s Engineering Workplace software, ensuring PROFINET device names and PROFIBUS DP addresses comply with ATEX zone requirements.

Mount the SD822 3BSC610038R1 on a DIN rail with 30mm clearance for thermal expansion. Connect dual redundant 24V DC inputs using ABB’s TB841 terminal blocks (1.5 N·m torque). Configure communication parameters via ABB’s Engineering Workplace software, ensuring PROFINET device names and PROFIBUS DP addresses comply with ATEX zone requirements.

Maintenance Recommendations:

- Perform quarterly thermal imaging inspections to detect hotspots in extreme-temperature environments.

- Update firmware annually via ABB’s Remote Support Portal to unlock ATEX-specific features.

- Clean the enclosure with a non-conductive solvent to maintain IP20 protection in dusty conditions.

- Replace the module every 10 years (MTBF) or after 150,000 hours of operation.

- For PROFIBUS DP networks, check segment termination resistors monthly in high-vibration settings.

Product Assurance

ABB guarantees the SD822 3BSC610038R1 with an 18-month warranty, covering defects in materials and workmanship. Our global service network provides 24/7 technical support, including remote diagnostics via the Ability™ platform and on-site assistance from ATEX-certified engineers. All modules undergo rigorous testing to meet ISO 9001, IEC 61131-2, and ATEX standards, ensuring reliable operation in mission-critical applications. For high-reliability needs, ABB offers 5-year extended warranties and proactive component replacement programs, with priority inventory allocation for offshore projects.

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com