Description

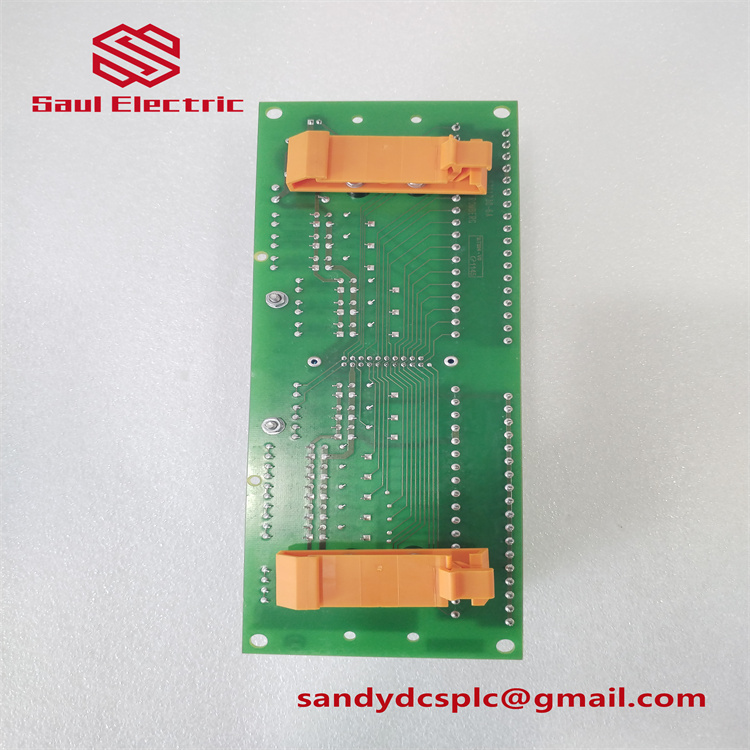

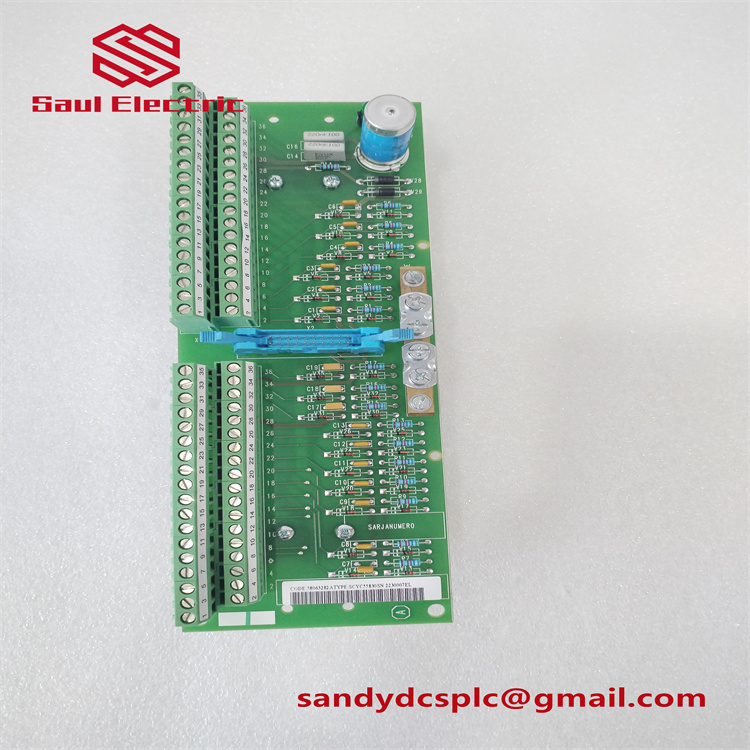

ABB SCYC51213 63911607C: High-Performance Multi-Channel Pulse Trigger Board for Industrial Automation

Product Overview

The ABB SCYC51213 63911607C is a high-reliability multi-channel pulse trigger board designed for mission-critical industrial power control and automation systems. As part of ABB’s advanced SCYC5100 series, this module delivers precise pulse generation and synchronization for power semiconductor devices (e.g., thyristors, IGBTs) in applications such as motor control, power system protection, and process automation. The 63911607C variant introduces a 32-bit ARM Cortex-A53 processor and 24 isolated pulse outputs, making it ideal for complex setups requiring high-channel density and real-time performance.

Engineered for harsh industrial environments, the SCYC51213 63911607C features a dual-system redundancy architecture that ensures continuous operation during power fluctuations or component failures. Its IP66-rated enclosure and enhanced EMI shielding (reducing interference by 40%) enable reliable performance in high-noise environments like steel mills and offshore platforms. The module seamlessly integrates with ABB’s Advant OCS and AC800F DCS systems, supporting modern protocols like OPC UA for Industry 4.0 compatibility.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB SCYC51213 63911607C |

| Manufacturer | ABB |

| Product Type | Multi-Channel Pulse Trigger Board |

| Input Voltage | 24V DC (±15%) with dual redundant inputs |

| Output Channels | 24 isolated pulse outputs (adjustable: 0.05ms–10s pulse width) |

| Pulse Amplitude | 24V DC–300V DC (±0.03% accuracy) |

| Communication Protocols | Modbus RTU, PROFIBUS DP, Ethernet, OPC UA, CANopen |

| Processor | 32-bit ARM Cortex-A53 (1.5 GHz, 60% faster than previous models) |

| Memory | 64 MB RAM + 128 MB flash (expandable via S100 I/O bus) |

| Operating Temperature | -35°C to +80°C (ambient) |

| Response Time | ≤0.5ms (sub-millisecond synchronization) |

| Enclosure Rating | IP66 (NEMA 4X compliant for outdoor use) |

| Certifications | CE, UL 508, IEC 61508 SIL3, RoHS |

| Physical Dimensions | 280mm x 200mm x 70mm |

| Weight | ~3.2kg |

| Mounting | DIN rail (EN 50022) or panel-mounted with vibration damping |

Key Features and Advantages

High-Channel Density and Precision:

The SCYC51213 63911607C supports 24 isolated pulse outputs with ±0.03% amplitude accuracy, enabling simultaneous control of multiple power semiconductors in complex systems like multi-axis robotic drives or high-voltage inverters. Its sub-millisecond response time (≤0.5ms) ensures precise synchronization in high-speed applications.

The SCYC51213 63911607C supports 24 isolated pulse outputs with ±0.03% amplitude accuracy, enabling simultaneous control of multiple power semiconductors in complex systems like multi-axis robotic drives or high-voltage inverters. Its sub-millisecond response time (≤0.5ms) ensures precise synchronization in high-speed applications.

Advanced Processing and Redundancy:

Equipped with a 1.5 GHz ARM Cortex-A53 processor, the module handles complex control algorithms for real-time data processing in smart grids and renewable energy systems. The dual-system architecture with redundant power inputs minimizes downtime, while hot-swap capabilities allow maintenance without system shutdowns.

Equipped with a 1.5 GHz ARM Cortex-A53 processor, the module handles complex control algorithms for real-time data processing in smart grids and renewable energy systems. The dual-system architecture with redundant power inputs minimizes downtime, while hot-swap capabilities allow maintenance without system shutdowns.

Enhanced Environmental Resilience:

The IP66-rated enclosure protects against dust and high-pressure water jets, making it suitable for outdoor installations or harsh industrial environments. Upgraded EMI shielding reduces interference by 40%, ensuring stable operation near heavy machinery or high-voltage equipment.

The IP66-rated enclosure protects against dust and high-pressure water jets, making it suitable for outdoor installations or harsh industrial environments. Upgraded EMI shielding reduces interference by 40%, ensuring stable operation near heavy machinery or high-voltage equipment.

Future-Ready Connectivity:

Support for OPC UA and CANopen enables seamless integration with cloud-based monitoring platforms (e.g., ABB Ability™) for predictive maintenance. Backward compatibility with legacy protocols (Modbus RTU, PROFIBUS DP) ensures integration with hybrid control systems.

Support for OPC UA and CANopen enables seamless integration with cloud-based monitoring platforms (e.g., ABB Ability™) for predictive maintenance. Backward compatibility with legacy protocols (Modbus RTU, PROFIBUS DP) ensures integration with hybrid control systems.

Applications

The SCYC51213 63911607C excels in industries requiring high-channel precision and reliability:

- Renewable Energy:

- Grid-tied inverter control in utility-scale solar/wind farms, supporting dynamic voltage regulation.

- Energy storage system (ESS) management for microgrids.

- Heavy Manufacturing:

- Multi-axis motion control in automotive body shops and metal processing plants.

- High-precision triggering for induction heating systems in steel production.

- Power Distribution:

- Fault current limiting in medium-voltage substations.

- Static var compensation (SVC) for voltage stability.

- Marine and Offshore:

- Subsea valve control with redundant power supplies.

- Generator synchronization in shipboard power systems.

Related Products

- ABB SCYC51204 63912476C: 16-channel variant for smaller-scale applications.

- ABB SCYC51030 58053899E: 24-channel legacy model with Motorola processor.

- ABB PM511MV08: PLC processor for unified control system integration.

- ABB CI535: PROFIBUS DP/Modbus RTU communication module.

- ABB AC800F DCS: Distributed control system for large-scale automation.

- ABB TB841 Terminal Blocks: Required for secure field wiring.

- ABB Engineering Workplace: Configuration software for parameter setup.

- ABB Ability™ Edge: Edge computing platform for real-time analytics.

- ABB SCYC51210 63911605C: 12-channel version with similar architecture.

- ABB Lifecycle Care Service: Extended warranty and maintenance plans.

Installation and Maintenance

Installation Preparation:

Mount the SCYC51213 63911607C on a DIN rail with 50mm clearance for airflow, using vibration-resistant brackets in high-vibration environments. Connect dual redundant 24V DC inputs with ABB’s TB841 terminal blocks (2.5 N·m torque). Configure channel parameters and communication protocols via ABB’s Engineering Workplace software, ensuring OPC UA settings align with network requirements.

Mount the SCYC51213 63911607C on a DIN rail with 50mm clearance for airflow, using vibration-resistant brackets in high-vibration environments. Connect dual redundant 24V DC inputs with ABB’s TB841 terminal blocks (2.5 N·m torque). Configure channel parameters and communication protocols via ABB’s Engineering Workplace software, ensuring OPC UA settings align with network requirements.

Maintenance Recommendations:

- Perform quarterly visual inspections for loose connections or thermal stress signs.

- Clean the enclosure with compressed air to maintain IP66 protection.

- Replace the cooling fan every 60,000 hours (MTBF) to prevent overheating.

- Update firmware annually via ABB’s Remote Support Portal to access new features (e.g., AI-based fault prediction).

- Calibrate pulse outputs every 2 years using ABB’s voltage reference kit.

Product Assurance

ABB guarantees the SCYC51213 63911607C with an 18-month warranty covering defects in materials and workmanship. Our global service network provides 24/7 technical support, including remote diagnostics via the Ability™ platform and on-site assistance from certified engineers. All modules undergo rigorous testing to meet ISO 9001, IEC 61508 SIL3, and NEMA 4X standards, ensuring reliable operation in mission-critical applications. For high-reliability needs, ABB offers 5-year extended warranties and proactive component replacement programs.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com