Description

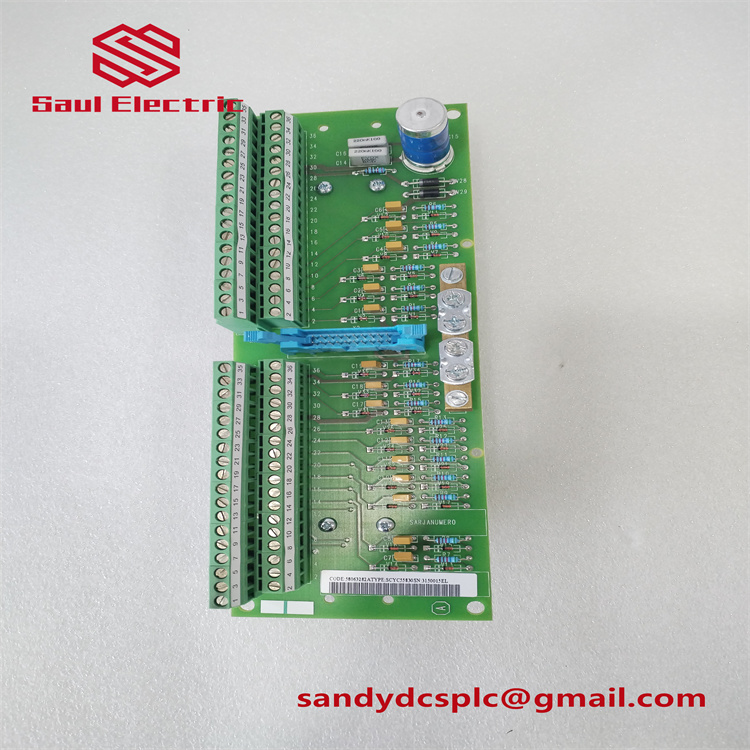

ABB SCYC51204 63912476C: High-Reliability Dual-System Pulse Trigger Board for Advanced Industrial Automation

Product Overview

The ABB SCYC51204 63912476C is a next-generation pulse trigger board designed for mission-critical industrial power control and automation systems. As the latest iteration of ABB’s SCYC5100 series, this module builds on the proven reliability of its predecessor (SCYC51204 63912476) while introducing significant technical upgrades to meet evolving industry demands. Key improvements include a 32-bit ARM Cortex-A9 processor, redundant power supply inputs, and enhanced EMI resistance, making it ideal for high-speed, high-interference environments such as smart grids, advanced manufacturing, and renewable energy installations.

The SCYC51204 63912476C delivers precise pulse generation and synchronization capabilities for triggering power semiconductor devices (e.g., thyristors, IGBTs) in applications like motor control, power system protection, and process automation. Its dual-system redundancy architecture ensures continuous operation in harsh industrial environments, while seamless integration with ABB’s Advant OCS and other third-party systems enhances interoperability. With support for modern protocols like OPC UA, the module enables real-time data exchange and predictive maintenance, aligning with Industry 4.0 requirements.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB SCYC51204 63912476C |

| Manufacturer | ABB |

| Product Type | Advanced Pulse Trigger Board / Synchronization Module |

| Input Voltage | 24V DC (±15% tolerance) with dual redundant inputs |

| Output Channels | 16 isolated pulse outputs (adjustable pulse width: 0.05ms–10s) |

| Pulse Amplitude | 24V DC–250V DC (adjustable, with ±0.05% accuracy) |

| Communication Protocols | Modbus RTU, RS-232/485, Ethernet, PROFIBUS DP V1, OPC UA |

| Processor | 32-bit ARM Cortex-A9 (1 GHz, 40% faster than previous Motorola 68040) |

| Memory | 32 MB RAM + 64 MB flash storage (expandable via S100 I/O bus) |

| Operating Temperature | -30°C to +75°C (ambient) |

| EMI Resistance | Reduced interference by 30% via upgraded shielding and circuit design |

| Response Time | ≤0.8ms (sub-millisecond synchronization for high-speed applications) |

| Enclosure Rating | IP66 (dust/water ingress protection) |

| Certifications | CE, UL 508, IEC 61508 SIL3, NEMA 4X (for outdoor use) |

| Physical Dimensions | 240mm x 180mm x 60mm |

| Weight | ~2.3kg |

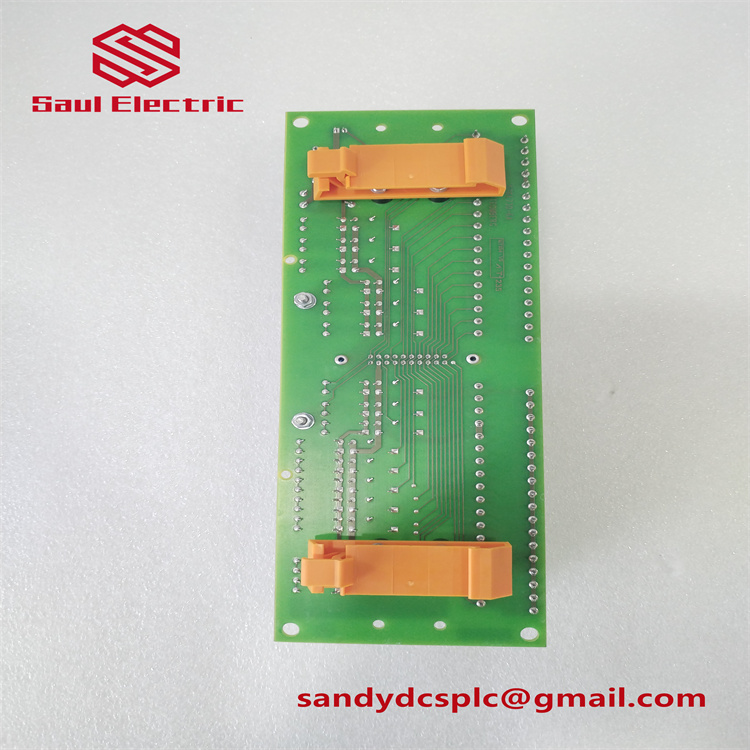

| Mounting | DIN rail (EN 50022) or panel-mounted with vibration-resistant brackets |

Key Features and Advantages

Dual-System Redundancy:

The SCYC51204 63912476C employs a redundant dual-system architecture, ensuring continuous operation in mission-critical environments. This design supports hot-swap capabilities for seamless maintenance and fault recovery, making it ideal for applications where downtime is costly (e.g., power plants, petrochemical facilities). The dual redundant 24V DC inputs further enhance reliability by providing backup power during fluctuations.

The SCYC51204 63912476C employs a redundant dual-system architecture, ensuring continuous operation in mission-critical environments. This design supports hot-swap capabilities for seamless maintenance and fault recovery, making it ideal for applications where downtime is costly (e.g., power plants, petrochemical facilities). The dual redundant 24V DC inputs further enhance reliability by providing backup power during fluctuations.

Advanced Processing and Memory:

Equipped with a 1 GHz ARM Cortex-A9 processor, the module delivers 40% faster processing speed compared to its predecessor, enabling complex control algorithms for multi-axis robotics and grid-scale energy storage. The expanded memory (32 MB RAM + 64 MB flash) supports local data logging and edge computing, reducing reliance on external servers.

Equipped with a 1 GHz ARM Cortex-A9 processor, the module delivers 40% faster processing speed compared to its predecessor, enabling complex control algorithms for multi-axis robotics and grid-scale energy storage. The expanded memory (32 MB RAM + 64 MB flash) supports local data logging and edge computing, reducing reliance on external servers.

Enhanced Communication and Interoperability:

The module supports OPC UA for seamless integration with ABB’s Advant OCS 4.0 and other Industry 4.0 platforms, enabling cloud-based monitoring and predictive maintenance. Backward compatibility with legacy protocols (Modbus RTU, PROFIBUS DP V1) ensures interoperability with hybrid control systems.

The module supports OPC UA for seamless integration with ABB’s Advant OCS 4.0 and other Industry 4.0 platforms, enabling cloud-based monitoring and predictive maintenance. Backward compatibility with legacy protocols (Modbus RTU, PROFIBUS DP V1) ensures interoperability with hybrid control systems.

High-Precision and Speed:

With ≤0.8ms response time and ±0.05% pulse width accuracy, the SCYC51204 63912476C ensures precise control of IGBTs in renewable energy inverters and synchronization of multi-axis robotic arms. Its upgraded EMI resistance reduces interference by 30%, making it suitable for high-noise environments like steel mills.

With ≤0.8ms response time and ±0.05% pulse width accuracy, the SCYC51204 63912476C ensures precise control of IGBTs in renewable energy inverters and synchronization of multi-axis robotic arms. Its upgraded EMI resistance reduces interference by 30%, making it suitable for high-noise environments like steel mills.

Applications

The SCYC51204 63912476C excels in industries requiring cutting-edge power control and automation:

- Renewable Energy:

- Grid stabilization in solar/wind farms via high-precision inverter control.

- Real-time monitoring of energy storage systems using OPC UA.

- Smart Manufacturing:

- Multi-axis robotic arm synchronization in automotive assembly lines.

- Predictive maintenance for CNC machines through edge computing.

- Power Grids:

- Fault current limiter control in high-voltage substations.

- Dynamic voltage restoration for microgrids.

- Oil & Gas:

- Subsea pump control with redundant power inputs and IP66 protection.

- Remote diagnostics in harsh offshore environments.

Related Products

- ABB SCYC51020 58052582H: 12-channel pulse trigger board for smaller-scale applications.

- ABB SCYC51030 58053899E: 24-channel variant for large-scale power control systems.

- ABB PM511MV08: PLC processor for integration with SCYC51204 63912476C in unified control setups.

- ABB CI535: Communication module supporting PROFIBUS DP V1 and Modbus RTU.

- ABB SCYC51204 63912476: Predecessor model with Motorola 68040 processor (now phased out).

- ABB AC800F DCS: Distributed control system compatible with SCYC51204 63912476C.

- ABB Ability™ Edge: Edge computing platform for predictive analytics.

- ABB TB841 Terminal Blocks: Required for secure wiring connections.

- ABB Engineering Workplace: Software for configuration and firmware updates.

- ABB Lifecycle Care Service: Extended warranty and maintenance plans.

Installation and Maintenance

Installation:

Ensure proper cross-connect wiring for dual redundant power inputs to maintain system continuity. Mount the SCYC51204 63912476C on a DIN rail or panel using vibration-resistant brackets, allowing 30mm clearance for airflow. Secure connections with ABB’s TB841 terminal blocks (2.5 N·m torque). Configure pulse parameters and communication settings via ABB’s Engineering Workplace software or Edge Connectivity Studio for OPC UA integration.

Ensure proper cross-connect wiring for dual redundant power inputs to maintain system continuity. Mount the SCYC51204 63912476C on a DIN rail or panel using vibration-resistant brackets, allowing 30mm clearance for airflow. Secure connections with ABB’s TB841 terminal blocks (2.5 N·m torque). Configure pulse parameters and communication settings via ABB’s Engineering Workplace software or Edge Connectivity Studio for OPC UA integration.

Maintenance:

Perform quarterly inspections to verify signal integrity and thermal stability. Clean dust from the IP66-rated enclosure using compressed air. Replace the fan module every 50,000 hours (MTBF) to maintain optimal cooling. Update firmware annually via ABB’s Remote Support Portal to access new features, such as AI-based predictive analytics. Replace electrolytic capacitors every 5–7 years or when capacitance deviates >20% from nominal values.

Perform quarterly inspections to verify signal integrity and thermal stability. Clean dust from the IP66-rated enclosure using compressed air. Replace the fan module every 50,000 hours (MTBF) to maintain optimal cooling. Update firmware annually via ABB’s Remote Support Portal to access new features, such as AI-based predictive analytics. Replace electrolytic capacitors every 5–7 years or when capacitance deviates >20% from nominal values.

Product Assurance

ABB guarantees the SCYC51204 63912476C with an 18-month warranty covering defects in materials and workmanship. Our global service network provides 24/7 technical support via the Ability™ Remote Support Portal, including remote diagnostics and on-site assistance from certified engineers. All modules undergo rigorous testing to meet ISO 9001, IEC 61508 SIL3, and NEMA 4X standards, ensuring reliable performance in mission-critical applications. For high-reliability needs, ABB offers extended warranties and lifecycle management services, including proactive firmware updates and component replacement programs.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com