Description

ABB SAFT110: Advanced Safety Termination Module for High-Reliability Industrial Automation

Product Overview

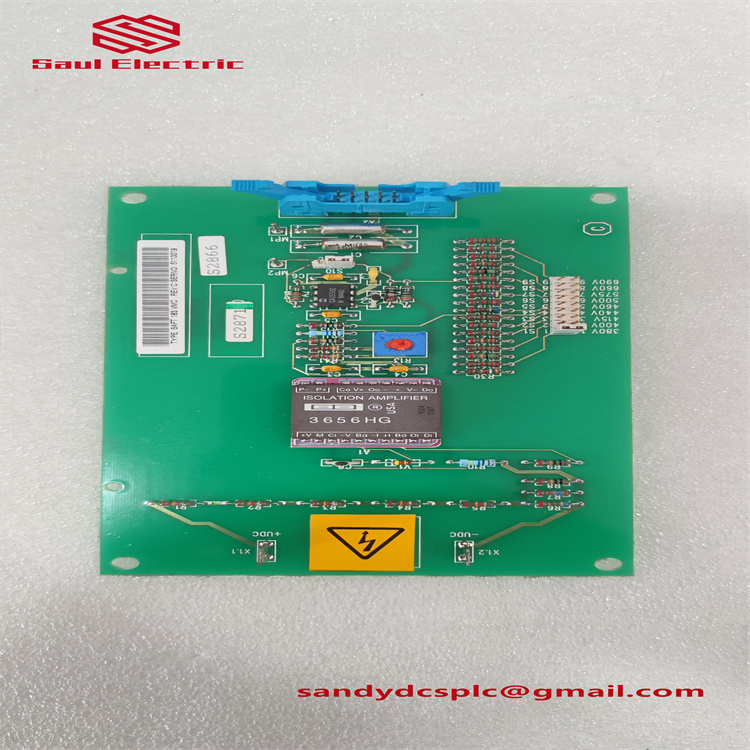

The ABB SAFT110 is a cutting-edge safety termination module designed for mission-critical industrial applications that demand precise signal conditioning and fail-safe integration of field devices. As a flagship model in ABB’s SafeLink series, the SAFT110 elevates safety system performance with enhanced processing capabilities and expanded connectivity, serving as a central hub for connecting safety sensors, actuators, and controllers in environments where operational integrity is non-negotiable.

Engineered to exceed SIL3 safety integrity level (per IEC 61508), the SAFT110 features a quadruple-channel redundant design, providing dual-layer fault detection for short circuits, open loops, and component failures. Its DIN rail-mountable form factor (120 x 60 x 40 mm) balances compactness with expandability, while the IP20-rated enclosure ensures protection against dust and accidental contact. The module integrates seamlessly with ABB’s AC800M DCS and PLCnext Technology platforms, enabling real-time monitoring via ABB’s Ability™ digital ecosystem for predictive maintenance and proactive safety management.

Key innovations include adaptive signal isolation, high-speed diagnostic feedback, and multi-protocol communication support. With support for PROFINET, EtherCAT, and Modbus RTU, the SAFT110 bridges legacy and modern safety networks, while its hot-swappable architecture allows maintenance without system shutdowns. The module’s advanced signal conditioning ensures accurate transmission of safety-critical signals (e.g., emergency stop inputs, safety light curtain outputs) with sub-millisecond response times.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB SAFT110 |

| Manufacturer | ABB |

| Product Type | Advanced Safety Termination Module |

| Safety Integrity Level | SIL3 (IEC 61508) |

| Input Voltage | DC 24V ±15% |

| Output Voltage | DC 24V (galvanically isolated) |

| Signal Channels | 8 channels (quadruple-channel design) |

| Communication Protocols | PROFINET, EtherCAT, Modbus RTU, OPC UA |

| Operating Temperature | -30°C to +75°C |

| Physical Dimensions | 120 x 60 x 40 mm |

| Weight | ~220g |

| Mounting | DIN rail (EN 50022) |

| Enclosure Rating | IP20 |

| Certifications | CE, UL 508, IEC 61508 SIL3, ATEX/IECEx (for hazardous areas) |

| MTBF | >200,000 hours |

Key Features and Advantages

Enhanced Safety Redundancy: The SAFT110’s quadruple-channel architecture provides dual-layer redundancy, with each channel independently monitored for faults. This design achieves a diagnostic coverage rate of 99.8%, exceeding industry standards for safety-critical systems in automotive manufacturing and chemical processing.

High-Speed Processing: Equipped with a dual-core microprocessor, the module processes safety signals in <1ms, enabling rapid response to emergency conditions. The adaptive signal filtering reduces noise interference, ensuring reliable operation in environments with electromagnetic disturbances.

Universal Connectivity: Support for PROFINET, EtherCAT, and OPC UA enables seamless integration with diverse control systems. The module’s built-in web server allows remote configuration via standard browsers, eliminating the need for proprietary software tools.

Predictive Maintenance: Real-time health monitoring features track component wear and voltage fluctuations, generating proactive alerts via the Ability™ platform. This reduces unplanned downtime by up to 40% compared to traditional safety modules.

Modular Design: The SAFT110 supports field-upgradable firmware and optional expansion modules (e.g., analog input/output cards), adapting to evolving process requirements without hardware replacement.

Applications

The ABB SAFT110 is optimized for industries with strict safety and reliability requirements:

- Automotive Manufacturing: Ensuring safe operation of robotic welding cells, paint booths, and conveyor systems by integrating emergency stops, safety interlocks, and light curtains.

- Oil & Gas Refineries: Safeguarding critical processes by monitoring pressure switches, flame detectors, and emergency shutdown valves in compliance with SIL3 standards.

- Pharmaceutical Production: Maintaining sterile environments by controlling access to cleanrooms and monitoring equipment interlocks for GMP-compliant operations.

- Aerospace Manufacturing: Managing safety-critical signals in aircraft component testing facilities, including pressure vessels and high-voltage systems.

- Nuclear Power Plants: Enabling fail-safe control of reactor cooling systems and radiation monitoring devices, adhering to strict regulatory requirements.

By integrating with ABB’s Emax 2 circuit breakers and SafetyPLC systems, the SAFT110 forms a comprehensive safety ecosystem that minimizes risk while maximizing operational efficiency.

Related Products

- ABB SAFT103: Base model with 4 channels and SIL2 certification, ideal for mid-level safety applications.

- ABB SAFT121PAC: High-current variant for heavy machinery, supporting up to 10A per channel.

- ABB AC500-S Safety PLC: Complementary controller for distributed safety systems, compatible with the SAFT110 via PROFINET.

- ABB DSCS131 Process Unit: High-performance module for integrating safety signals into ABB’s AC800M DCS.

- ABB SAMT11 Tamper Detection Module: Enhances security by monitoring unauthorized access to control panels.

- ABB SAFT163IOC: Analog I/O extension for precision temperature and pressure monitoring in safety loops.

- ABB SAFT183VMC: Voltage monitoring module with built-in surge protection for harsh industrial environments.

- ABB TB841 Terminal Block: Compatible wiring solution for simplifying field connections to the SAFT110.

Installation and Maintenance

Installation Preparation:

- Verify the power supply matches the SAFT110’s DC 24V ±15% requirements and ensure grounding complies with IEC 61010 standards to prevent electrical interference.

- Mount the module on a DIN rail within a certified safety-rated enclosure, allowing 20mm clearance for heat dissipation.

- Connect field devices using shielded cables terminated with ABB’s TB841 terminal blocks, tightening to 2.5 N·m torque for secure connections.

- Configure the module via ABB’s Safety Toolbox software, assigning channels to safety functions and enabling protocol-specific parameters (e.g., PROFINET update rate).

Maintenance Recommendations:

- Regularly review diagnostic reports generated by the module’s built-in web interface, addressing alerts for voltage deviations or channel degradation promptly.

- Perform quarterly visual inspections to check for loose connections or physical damage, replacing faulty components immediately to maintain SIL3 integrity.

- Update firmware annually using ABB’s Remote Support Portal to incorporate the latest safety algorithms and cybersecurity patches.

- Conduct annual functional safety tests with ABB’s SIL3 Calibration Kit to verify trip thresholds and diagnostic coverage.

Product Assurance

ABB stands behind the SAFT110 with a comprehensive 1-year warranty covering defects in materials and workmanship. Our global service network provides 24/7 technical support, including remote diagnostics via the Ability™ platform and on-site commissioning by certified safety engineers. All modules undergo rigorous testing to meet ISO 13849-1 PL e and IEC 61508 SIL3 standards, ensuring consistent performance in the most demanding environments. For mission-critical applications, ABB offers extended warranties and lifecycle management services to guarantee long-term reliability.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com