Description

Product Overview

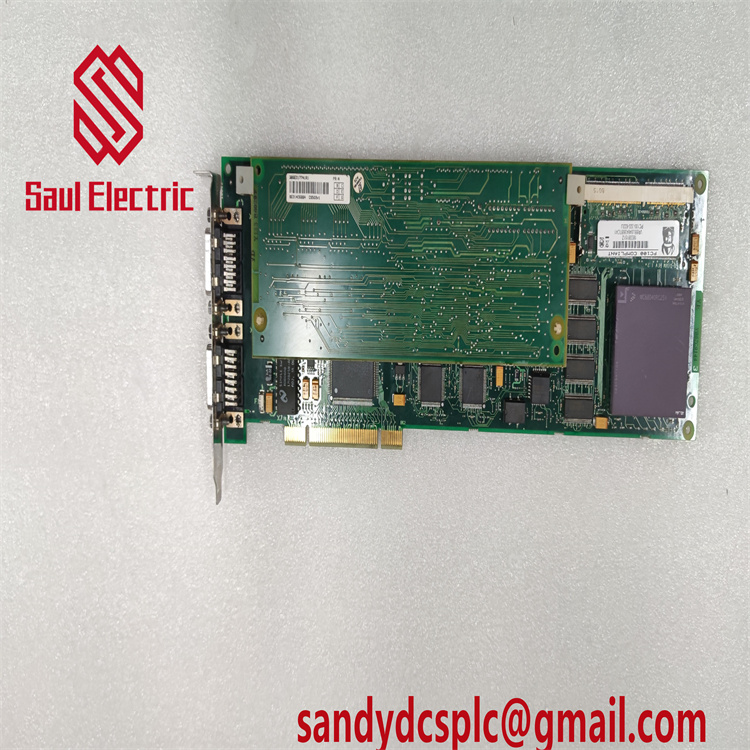

The ABB R1091 is a high-precision Industrial Control Module engineered to deliver reliable automation solutions across manufacturing, energy, and infrastructure sectors. As part of ABB’s AC 800M Distributed Control System (DCS) portfolio, this module integrates seamlessly into complex industrial setups, providing advanced process control, real-time monitoring, and data acquisition capabilities. Designed for harsh environments, the ABB R1091 ensures consistent performance in extreme temperatures (-40°C to +70°C) and offers IP65-rated protection against dust and moisture, making it ideal for applications in chemical plants, power generation facilities, and heavy machinery manufacturing.

With support for multiple industrial communication protocols—including Ethernet, Modbus, and PROFIBUS—the ABB R1091 bridges PLCs, DCS systems, and field devices, enabling efficient data exchange and system synchronization. Its configurable I/O architecture (16 digital inputs, 16 digital outputs, and 8 analog channels) adapts to diverse automation requirements, from simple machine control to sophisticated process optimization. The module’s compact form factor (170 mm × 90 mm × 60 mm) and DIN rail mounting design simplify installation in space-constrained control panels, while its 2.5 kg lightweight construction facilitates easy handling and maintenance.

Equipped with PID control algorithms and advanced diagnostic tools, the ABB R1091 enhances system stability and reduces downtime by enabling predictive maintenance and rapid error resolution. Its 100–240 V AC input voltage range and 24 V DC output ensure compatibility with global power standards, while redundant power supply options further enhance reliability in mission-critical operations. By combining robust hardware with intuitive software integration via ABB’s Automation Builder, the ABB R1091 empowers industries to achieve higher operational efficiency and cost savings.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB R1091 |

| Manufacturer | ABB |

| Product Type | Industrial Control Module |

| Input Voltage Range | 100–240 V AC |

| Output Voltage | 24 V DC |

| Communication Protocols | Ethernet, Modbus RTU/TCP, PROFIBUS DP |

| I/O Channels | 16 DI, 16 DO, 8 AI, 4 AO |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 170 mm × 90 mm × 60 mm |

| Weight | 2.5 kg |

| Environmental Rating | IP65 |

| Certifications | CE, UL 61010 |

Key Features and Advantages

Multi-Protocol Connectivity: The ABB R1091 supports Ethernet, Modbus, and PROFIBUS, eliminating the need for additional gateways and enabling seamless integration with both legacy and modern industrial systems. This versatility ensures compatibility with ABB’s AC 800M controllers and third-party devices, streamlining complex automation workflows.

Rugged Environmental Resilience: Built with an IP65-rated enclosure and a wide operating temperature range, the module withstands extreme conditions, including high vibration, dust, and moisture. Its robust design reduces maintenance costs and extends lifecycle, making it suitable for oil refineries, mining operations, and outdoor infrastructure projects.

Flexible I/O Configuration: With 16 digital and 8 analog channels, the ABB R1091 adapts to diverse applications, from monitoring sensor data in chemical reactors to controlling robotic arms in automotive assembly lines. Configurable I/O points allow users to tailor the module to specific needs without hardware modifications.

Advanced Control Capabilities: The module’s PID control algorithms and real-time data processing ensure precise regulation of process variables, enhancing system efficiency and product quality. Its diagnostic tools provide actionable insights into equipment health, enabling proactive maintenance and minimizing unplanned outages.

Easy Integration and Scalability: The ABB R1091’s compact size and DIN rail mounting simplify installation, while ABB’s Automation Builder software enables intuitive configuration and programming. The module supports hot-swap functionality, allowing system upgrades without downtime, and integrates seamlessly with ABB’s AC 800M redundancy systems for high-availability applications.

Application Areas

Power Generation: The ABB R1091 monitors turbine operations, grid synchronization, and environmental compliance in power plants. Its real-time data visualization and Modbus connectivity ensure efficient energy management and regulatory adherence, even in high-voltage substations.

Process Industries: Deployed in chemical and petrochemical facilities, the module controls temperature, pressure, and flow in distillation columns and reactors. Its IP65-rated design ensures reliable performance in corrosive environments, while PROFIBUS integration enables centralized monitoring of distributed I/O systems.

Manufacturing Automation: In automotive and food processing lines, the ABB R1091 coordinates conveyor systems, quality inspection stations, and packaging machinery. Its Ethernet capabilities facilitate cloud-based analytics for optimizing production speed and reducing waste.

Water and Wastewater Treatment: The module manages pump stations, filtration systems, and chemical dosing processes, ensuring regulatory compliance and resource efficiency. Remote diagnostics via Ethernet enable real-time adjustments and reduce operational costs in wastewater treatment plants.

Related Products

| Model | Relationship/Use Case |

|---|---|

| ABB PM803F | High-performance controller module compatible with ABB R1091 for complex automation tasks. |

| ABB CI854AK01 | PROFINET communication module for advanced network integration with ABB’s AC 800M system. |

| ABB DSQC 377A | Robot-to-PC interface module for integrating ABB robots with PLCs in manufacturing lines. |

| ABB TB521 | Terminal block for securing communication interfaces, enhancing system reliability. |

| ABB EN401 | Ethernet interface module for extending network connectivity in distributed control systems. |

Installation and Maintenance

Installation Preparation:

Ensure the control panel meets IP65 environmental requirements and has sufficient space for the ABB R1091’s dimensions (170 mm × 90 mm × 60 mm). Use shielded twisted-pair cables for PROFIBUS and Ethernet connections to minimize interference. Configure network settings via ABB’s Automation Builder software, assigning static IP addresses for critical applications. Verify power supply compatibility (100–240 V AC) and secure the module to the DIN rail using M4 screws.

Ensure the control panel meets IP65 environmental requirements and has sufficient space for the ABB R1091’s dimensions (170 mm × 90 mm × 60 mm). Use shielded twisted-pair cables for PROFIBUS and Ethernet connections to minimize interference. Configure network settings via ABB’s Automation Builder software, assigning static IP addresses for critical applications. Verify power supply compatibility (100–240 V AC) and secure the module to the DIN rail using M4 screws.

Maintenance Recommendations:

Regularly inspect cable connections and clean the module with a dry, lint-free cloth to prevent dust accumulation. Update firmware biannually to access new features and security patches. Monitor LED indicators for power, network activity, and error status to identify issues promptly. ABB’s Global Service Network provides 24/7 technical support and rapid spare parts delivery, with a 3-day delivery time for stocked modules in Xiamen, China.

Regularly inspect cable connections and clean the module with a dry, lint-free cloth to prevent dust accumulation. Update firmware biannually to access new features and security patches. Monitor LED indicators for power, network activity, and error status to identify issues promptly. ABB’s Global Service Network provides 24/7 technical support and rapid spare parts delivery, with a 3-day delivery time for stocked modules in Xiamen, China.

Product Assurance

ABB guarantees the ABB R1091 with a 1-year standard warranty, covering defects in materials and workmanship. Customers can opt for ABB’s Extended Warranty Service (EWT), which extends coverage to 3 years for high-reliability applications, reducing lifecycle costs. The module is stocked in Xiamen, China, ensuring 3-day delivery after payment for urgent projects. ABB’s technical support team offers comprehensive guidance for configuration, troubleshooting, and system integration, ensuring seamless deployment across industries.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com