Description

Product Overview

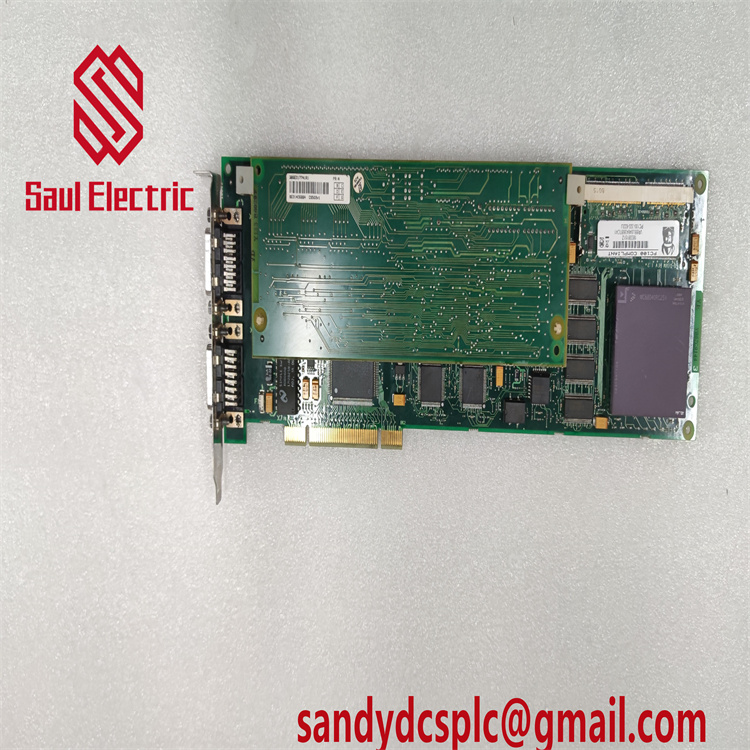

The ABB PU516A 3BSE032402R1 is a high-performance Engineering Interface Module designed for ABB’s Advant OCS and Advant Master industrial control systems. As the successor to the ABB PU516, this module serves as a critical bridge between engineering workstations and field-level controllers, enabling seamless configuration, monitoring, and diagnostics of complex industrial processes. The ABB PU516A integrates a PCI bus interface and 16 MB memory to support real-time data exchange and advanced programming capabilities, making it essential for mission-critical applications in industries such as oil & gas, power generation, and water treatment. Its compact design (32.3 cm × 12.6 cm × 2 cm) and rugged construction ensure reliable operation in harsh environments, while compatibility with ABB’s Automation Builder software streamlines system integration and maintenance 16.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB PU516A 3BSE032402R1 |

| Manufacturer | ABB |

| Product Type | Engineering Interface Module (Advant OCS Series) |

| Bus Interface | PCI (32-bit, 33 MHz) |

| Memory | 16 MB RAM |

| Communication Ports | 1x MB300 port, 1x RS-232 port |

| Power Supply | 5V DC (1A) |

| Operating Temperature | 0°C to +50°C |

| Storage Temperature | -20°C to +70°C |

| Dimensions | 32.3 cm × 12.6 cm × 2 cm |

| Weight | 0.34 kg |

| Certifications | CE, UL 60950-1, IP54 (environmental protection) |

| Compatibility | ABB Advant OCS, Advant Master, and AC 800M control systems |

| Mounting Method | PCI slot installation |

Key Features and Advantages

Advanced Engineering Capabilities

The ABB PU516A acts as a dedicated interface for programming and configuring ABB’s Advant OCS controllers, allowing engineers to develop, test, and deploy control logic efficiently. Its MB300 port enables high-speed communication with ABB’s MasterBus 300 network, while the RS-232 port supports legacy device connectivity. The module’s 16 MB memory ensures smooth handling of large-scale control programs and diagnostic data 16.

Rugged Industrial Design

Built to withstand industrial environments, the ABB PU516A features an IP54-rated enclosure that protects against dust and splashes. Its wide operating temperature range (0°C to +50°C) and robust vibration resistance (IEC 60068-2-6) make it suitable for applications in oil rigs, power plants, and manufacturing facilities where reliability is critical 610.

Seamless System Integration

As part of ABB’s modular automation platform, the ABB PU516A integrates seamlessly with ABB’s AC 800M controllers and S800 I/O systems. This interoperability simplifies system expansion and reduces downtime during upgrades. The module’s PCI interface ensures compatibility with standard industrial PCs, eliminating the need for specialized hardware 16.

Enhanced Diagnostics and Maintenance

The ABB PU516A includes built-in diagnostic tools that monitor system health in real time, alerting operators to potential issues such as communication failures or memory overload. Its hot-swappable design allows for component replacement without disrupting system operation, minimizing maintenance downtime 110.

Application Areas

Process Control Systems

Deployed in chemical plants and refineries to manage complex processes like distillation, polymerization, and quality control. The ABB PU516A ensures precise coordination between field devices and supervisory systems, optimizing production efficiency 610.

Power Generation and Distribution

Used in power plants to configure and monitor turbine control systems, generator synchronization, and grid stabilization. Its real-time data processing capabilities help maintain grid stability and reduce downtime during load fluctuations 610.

Water and Wastewater Treatment

Applied in water treatment facilities to manage pumping systems, filtration processes, and environmental monitoring. The ABB PU516A supports remote diagnostics, enabling proactive maintenance of critical infrastructure 610.

Manufacturing Automation

Integrated into factory automation systems to program and monitor robotics, conveyor belts, and quality inspection stations. Its compatibility with ABB’s Automation Builder software simplifies the development of custom control solutions 610.

Related Products

| Model | Relationship/Use Case |

|---|---|

| ABB PU516 3BSE013064R1 | Predecessor module with identical functionality but lower compatibility with modern systems. |

| ABB PU515A 3BSE032401R1 | High-performance RTA module often paired with PU516A for complex control setups. |

| ABB CI524 | Profibus DP communication module that complements PU516A for extended network connectivity. |

| ABB PM510 | I/O module designed for seamless integration with PU516A in modular control systems. |

| ABB AI542 | Analog input module used alongside PU516A for signal acquisition in process control. |

| ABB DI521 | Digital input module for monitoring binary signals in industrial automation. |

Installation and Maintenance

Installation Preparation:

Ensure the host PC’s PCI slot supports 32-bit, 33 MHz operation. Power off the system before installing the ABB PU516A and secure it using the provided mounting bracket. Connect the MB300 and RS-232 cables with torque-controlled connectors (8 N·m). Use ABB’s Automation Builder software to initialize the module and configure communication parameters 16.

Ensure the host PC’s PCI slot supports 32-bit, 33 MHz operation. Power off the system before installing the ABB PU516A and secure it using the provided mounting bracket. Connect the MB300 and RS-232 cables with torque-controlled connectors (8 N·m). Use ABB’s Automation Builder software to initialize the module and configure communication parameters 16.

Maintenance Recommendations:

Conduct quarterly inspections to check for loose connections or thermal stress. Clean the module with a static-free cloth to prevent dust accumulation. Update firmware regularly to access new features and security patches. ABB’s Predictive Maintenance Service offers remote health monitoring to identify potential failures before they occur. Note: When replacing the ABB PU516A, return the old part (RMA process) to avoid additional charges 16.

Conduct quarterly inspections to check for loose connections or thermal stress. Clean the module with a static-free cloth to prevent dust accumulation. Update firmware regularly to access new features and security patches. ABB’s Predictive Maintenance Service offers remote health monitoring to identify potential failures before they occur. Note: When replacing the ABB PU516A, return the old part (RMA process) to avoid additional charges 16.

Product Assurance

ABB provides a 1-year standard warranty for the ABB PU516A 3BSE032402R1, covering defects in materials and workmanship. Customers benefit from ABB’s Global Service Network, which offers 24/7 technical support, rapid spare parts delivery, and on-site maintenance. The module undergoes rigorous testing for electromagnetic compatibility (EMC) and environmental resilience to ensure compliance with international standards. For high-reliability applications, ABB’s Extended Warranty Service (EWT) extends coverage to 5 years, reducing lifecycle costs 110.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com