Description

Product Overview

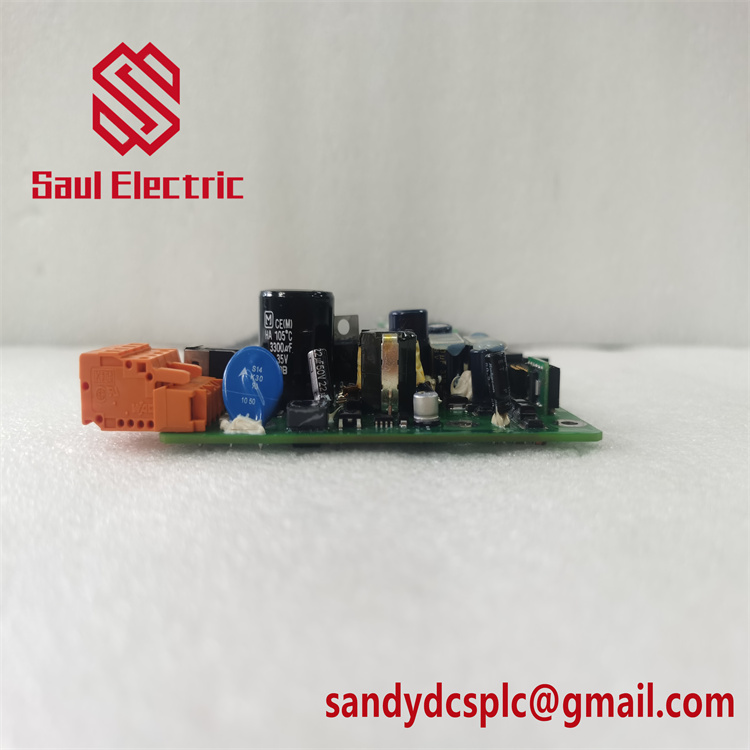

The ABB PPC380AE02 is a high-availability redundant controller module designed for mission-critical industrial automation within ABB’s PPC (Process Control Controller) series. Engineered as a dual-processor kit, this module builds on the robust foundation of the ABB PPC380AE01 by adding hot-swappable redundancy, making it ideal for applications where uninterrupted operation is non-negotiable. The ABB PPC380AE02 supports seamless integration with ABB’s AC 800M and 800xA systems, delivering real-time control, advanced diagnostics, and scalable connectivity for complex processes in sectors like power generation, oil & gas, and manufacturing.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB PPC380AE02 |

| Manufacturer | ABB |

| Product Type | Redundant Industrial Controller Kit (PPC Series) |

| Processor | Dual-core ARM Cortex-A9 1.2 GHz (per module), dual-processor redundancy |

| Memory | 2 GB DDR3 RAM per module, 8 GB eMMC storage per module |

| Communication Interfaces | 4 × Gigabit Ethernet (10/100/1000 Mbit/s), 6 × USB 2.0, 4 × RS485/422 (dual-module) |

| Redundancy Support | Hot standby redundancy (switchover ≤5 ms), automatic failover diagnostics |

| Power Supply | 24 V DC (18–32 V DC), 30 W typical consumption (dual modules) |

| Operating Temperature | -20°C to +60°C (standard), -40°C to +70°C with extended kit |

| Safety Certification | CE, UL, cUL, ATEX Zone 2, SIL2 (IEC 61508) |

| Vibration Resistance | 5–500 Hz, 2 g (IEC 60068-2-6) |

| Protection Class | IP20 (conformal coating optional) |

| Dimensions | 119 mm × 186 mm × 135 mm (per module), total kit size: 240 mm × 186 mm × 135 mm |

| Weight | 3.2 kg (kit) |

| Protocol Support | Profinet RT, Ethernet/IP, Modbus TCP, OPC UA, ABB Ability™ integration |

Key Features and Advantages

High-Availability Redundancy

The ABB PPC380AE02 features a dual-controller architecture, enabling hot standby redundancy with switchover times ≤5 ms. This eliminates single points of failure in critical systems, such as emergency shutdown (ESD) or continuous manufacturing lines, where downtime risks production losses or safety hazards.

Enhanced Processing Power

Each module in the kit houses a dual-core ARM Cortex-A9 processor, supporting parallel task execution for complex control algorithms. With 2 GB DDR3 RAM per module, the PPC380AE02 handles up to 2,000 I/O points and 10,000 tags, making it suitable for large-scale automation networks.

Rugged Redundant Design

Designed for harsh environments, the kit withstands -20°C to +60°C temperatures and 2 g vibrations. Dual power inputs and redundant communication paths (Ethernet, serial) ensure continuous operation in offshore platforms, mining sites, or outdoor installations.

Seamless System Integration

The PPC380AE02 integrates with ABB’s 800xA System via OPC UA and supports multi-protocol connectivity (Profinet, Ethernet/IP), enabling unified control across diverse industrial networks. Its modular design allows phased upgrades without disrupting existing setups.

Application Areas

Critical Infrastructure

Deployed in power plants for turbine control and grid stabilization, the ABB PPC380AE02 ensures uninterrupted energy distribution. Its SIL2 certification makes it suitable for safety-critical applications like emergency power systems.

Oil & Gas Production

Used in offshore platforms and refineries to manage wellhead operations, pipeline monitoring, and flare systems. The kit’s ATEX compliance allows operation in explosive zones, while redundant communication prevents data loss in remote locations.

Pharmaceutical & Chemical Processing

Manages batch processes, sterilization systems, and quality control in regulated industries. The PPC380AE02’s redundant architecture maintains compliance with GMP standards by minimizing process interruptions.

Smart Manufacturing

Optimizes robotic assembly lines, predictive maintenance, and IoT integration in smart factories. The kit’s high-speed processing supports real-time data analytics for process optimization and downtime reduction.

Related Products

| Model | Relationship/Use Case |

|---|---|

| PPC380AE01 | Non-redundant base model, compatible as a single controller in non-critical setups. |

| PPC322AEV01 | Lower-performance variant for small-scale systems, shares software compatibility. |

| PM867AK01-eA | High-performance AC800M CPU for redundant pairs, integrates with PPC380AE02 in hybrid DCS. |

| S800 I/O-eA Series | Extended-environment I/O modules (e.g., AI830-eA) to complement PPC380AE02 in harsh environments. |

| TB852-eA | Redundancy terminator for secure failover signaling in PPC380AE02 configurations. |

Installation and Maintenance

Installation Preparation

Mount the ABB PPC380AE02 kit on adjacent TP830 baseplates using DIN rail, ensuring 50 mm spacing for heat dissipation. Connect dual Ethernet links via TK851 RCU cables and terminate redundancy loops with TB852-eA modules. Use ABB’s Control Builder to configure active-standby roles and failover parameters.

Maintenance Recommendations

Conduct monthly health checks via ABB’s Remote Diagnostics Tool, monitoring CPU load, memory usage, and redundancy status. Replace backup batteries (model 4943013-6) annually to preserve program data. For hot-swappable module replacements, use anti-static gear and follow ABB’s service procedures to maintain system availability.

Product Assurance

ABB provides a 1-year warranty for the PPC380AE02 kit, covering manufacturing defects in both modules. Customers gain access to ABB’s 24/7 global support network, including remote troubleshooting, firmware updates, and expedited spare parts delivery. The kit undergoes rigorous testing for thermal cycling, vibration, and redundancy switching to ensure compliance with industrial standards.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com