Description

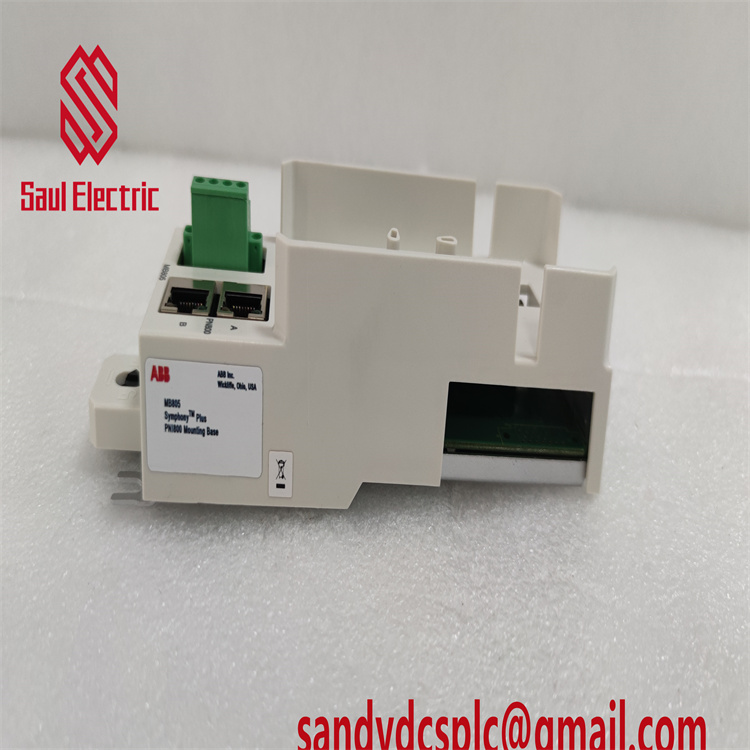

The ABB PNI800 is a Plant Network Interface Module designed to enable real-time communication between PC workstations and SD series controllers in industrial automation systems. It serves as a critical bridge for data exchange, configuration, and monitoring within ABB’s Symphony Plus and 800xA control environments. Below is a detailed overview based on verified specifications and application insights:

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB PNI800 (3BSE0xxxxxR1) |

| Manufacturer | ABB |

| Product Type | Plant Network Interface Module (Communication Gateway) |

| Processor | MCF5475 @ 256 MHz (32-bit RISC with error detection) |

| Memory | 64 MB DRAM, 4 MB flash for firmware storage |

| Communication Interfaces | 2 x RJ45 Ethernet (10/100 Mbit/s), 1 x Mini USB (diagnostics port) |

| Redundancy Support | IEC 62439 Parallel Redundancy Protocol (PRP) for network reliability |

| Power Supply | 24 V DC (19.2–30 V DC wide-range input, 3.5 W typical consumption) |

| Operating Temperature | 0°C to +55°C (standard), -20°C to +60°C with extended environment kit |

| Safety Certification | CE, UL, CSA (non-hazardous locations), RoHS/REACH compliant |

| Vibration Resistance | 5–500 Hz, 0.2 g (IEC 60068-2-6) |

| Protection Class | IP20 (conformal coating available for moisture resistance) |

| Dimensions | 170.18 mm × 73.66 mm × 243.84 mm (6.7″ × 2.9″ × 9.6″) |

| Weight | 0.38 kg (0.84 lbs) |

| Protocol Support | TCP/IP, Modbus TCP, UDP, Ethernet/IP, Profinet IO, Harmony API |

Key Features and Advantages

-

Real-Time Communication:

Enables bi-directional data exchange between engineering workstations (e.g., S+ Engineering) and SD controllers, supporting up to 200 concurrent connections and 30,000 HMI tags 5. This ensures seamless integration with SCADA systems and third-party software. -

Redundant Architecture:

Implements PRP redundancy to eliminate single points of failure, ensuring zero downtime in mission-critical applications like power distribution and process control 5. Dual Ethernet ports provide network resilience. -

Flexible Protocol Handling:

Supports industrial protocols (Modbus TCP, Profinet) and ABB-specific interfaces (Harmony API), making it suitable for hybrid automation setups 7. Its web server functionality allows remote administration and diagnostics. -

Scalable Design:

Compatible with ABB’s AC800M, 800xA, and Symphony Plus systems, the PNI800 supports phased expansions and integration with existing infrastructure 11. Hot-swappable capability simplifies maintenance without system shutdowns. -

Rugged Reliability:

Withstands harsh industrial conditions (vibration up to 0.2 g, wide temperature range) and complies with CE/UL/CSA standards. Optional conformal coating protects against dust and moisture 5.

Application Areas

- Industrial Automation:

Manages manufacturing lines (robotics, packaging) by bridging PLCs and HMIs for real-time monitoring and control. - Energy Management:

Integrates power generation systems (e.g., turbines, solar farms) with grid infrastructure, ensuring seamless data flow between SCADA and distributed controllers 22. - Water/Wastewater Treatment:

Coordinates pump stations, filtration systems, and chemical dosing processes via remote I/O and SCADA integration 1. - Transportation Infrastructure:

Controls metro systems, traffic lights, and tunnel ventilation by linking field devices to centralized control rooms.

Installation and Compatibility

- Hardware Integration:

Mounts on MB805 baseplates (DIN rail) and connects to SD controllers via PN800 Real-Time Control Network 5. Redundant configurations require TK850/TK851 cables for synchronization. - Software Configuration:

Configured using ABB’s 800xA Control Builder or S+ Engineering tools. Supports virtualization via VPNI software for cloud-based monitoring 5. - Compatibility:

Works with ABB’s S800 I/O modules and third-party devices via protocol gateways.

Product Assurance

- Warranty: 1–2 years (varies by supplier).

- Support: ABB’s global service network provides 24/7 technical assistance, including firmware updates and remote diagnostics 5.

- Delivery: Typically ships within 3–7 business days from stock 1.

Pricing and Availability

- Unit Price: $666–$2,000 (China market), depending on configuration and supplier 1325.

- Redundant Kit (PNI800K01): Includes dual modules, cables, and terminators, priced at ~¥6,999 23.

- Lead Time: 3–5 days for in-stock items 7.

Comparison with Related Models

| Model | Key Difference |

|---|---|

| PM866 | CPU module for control logic execution (non-safety applications) 24. |

| PM865 | SIL3-certified CPU for safety-critical systems (e.g., emergency shutdown) 24. |

| CI867-eA | Profibus communication module for localized I/O integration. |

Product Documentation

- User Manual: Covers installation, configuration, and troubleshooting (Document ID: 3BSE056248).

- Datasheet: Technical specifications and environmental ratings.

- Application Notes: Guides for integrating with 800xA and Symphony Plus systems.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com