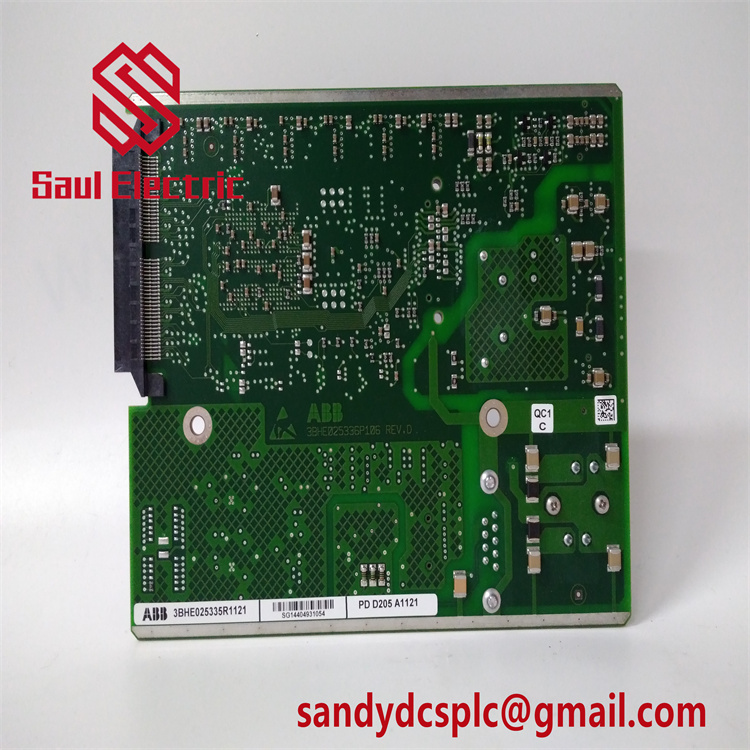

Description

The ABB PDP22-FBP is a PROFIBUS DP FieldBusPlug designed to enable seamless communication between ABB’s FBP (FieldBus Plug)-compatible devices (e.g., UMC universal motor controllers, soft starters, and sensors) and PROFIBUS DP networks. This module acts as a protocol bridge, allowing industrial automation systems to integrate legacy and modern equipment efficiently. Below is a detailed technical overview based on ABB’s official documentation and verified third-party sources 1712.

Key Features and Functionality

-

PROFIBUS DP-V0/V1 Compatibility:

Supports data transfer rates up to 12 Mbps and complies with PROFIBUS DP-V0 (basic) and DP-V1 (advanced diagnostics and parameterization) protocols. This makes it suitable for real-time control applications in manufacturing, power generation, and process industries 47. -

Bus-Neutral Interface Design:

Features a fieldbus-neutral interface that allows the same FBP device (e.g., UMC22) to be connected to different bus systems (e.g., Modbus RTU, DeviceNet) by simply swapping the FieldBusPlug module. This flexibility reduces hardware redundancy and simplifies system upgrades 112. -

IP65 Protection Rating:

Built with a rugged, sealed enclosure, the PDP22-FBP resists dust, water splashes, and oil mist, ensuring reliable operation in harsh industrial environments (e.g., motor control centers, offshore platforms) 46. -

Diagnostic and Status Monitoring:

Equipped with LED indicators for bus status (e.g., power, communication activity, errors) and device connectivity. This simplifies troubleshooting and maintenance 7. -

Hot-Swappable Design:

Supports online replacement of FBP devices without disrupting the PROFIBUS network, minimizing downtime in continuous production systems 712.

Technical Specifications

| Parameter | Value |

|---|---|

| Communication Protocol | PROFIBUS DP-V0/V1 |

| Data Rate | Up to 12 Mbps |

| Power Supply | 24V DC (±10%) 46 |

| Protection Rating | IP65 |

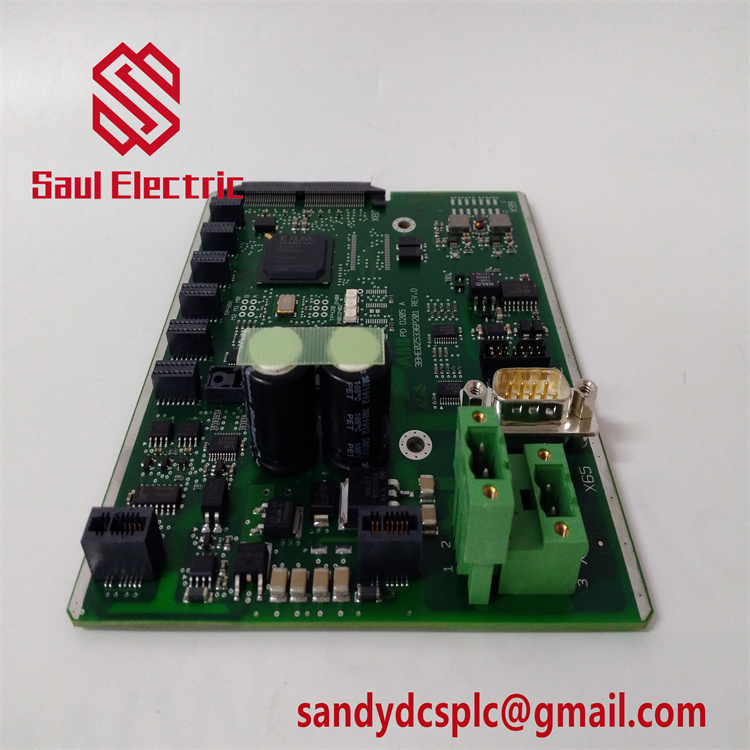

| Connectors | A-coded M12 plug for PROFIBUS DP network; FBP interface for device connection |

| Dimensions | ~112 mm (W) × 67 mm (H) × 26 mm (D) (similar to PDP22-FBP.500) 4 |

| Weight | ~0.468 kg (excluding cable) 4 |

| Certifications | CE, UL 508, CAN/CSA C22.2 No. 142 4 |

Applications

-

Motor Control Systems:

Connects UMC universal motor controllers and soft starters to PROFIBUS DP networks for real-time monitoring of motor parameters (e.g., current, temperature) and remote control 71012. -

Distributed I/O and Sensors:

Integrates MSD11 (motor protection circuit breakers) and MSR22 (thermal overload relays) into PROFIBUS DP systems for predictive maintenance and fault diagnostics 29. -

Process Automation:

Enables PROFIBUS DP communication for MFI21 (frequency converters) and other FBP-compatible devices in chemical plants, wastewater treatment facilities, and food processing lines 212. -

PLC Integration:

Works with PLCs like ABB’s AC 500 series and Siemens S7-300, allowing seamless data exchange between control systems and field devices. Note: When used with S7-300, communication length may be limited to 4 bytes due to protocol constraints 1113.

Configuration and Setup

-

Addressing:

Configure the PROFIBUS DP node address via DIP switches on the module. The address range is typically 1–99, with each PDP22-FBP representing a single node on the bus 9. -

Cabling:

Uses pre-assembled FBP cables (0.25–5 m lengths) with gold-plated connectors to minimize signal degradation. Terminal resistors (e.g., PDR11) must be installed at both ends of the bus segment 79. -

Software Tools:

- ABB AC 500 Programming Software: Configures the PDP22-FBP as a PROFIBUS DP slave device and maps I/O signals 11.

- GSD Files: Required for integrating the PDP22-FBP into Siemens TIA Portal or other third-party PLC environments 2.

Availability and Support

- New Units: Available through ABB’s authorized distributors (e.g., Teknihaus, CITSCORP) with a 1-year warranty. Lead times are typically 1–10 business days 56.

- Refurbished Units: Third-party suppliers like Xiamen Xingruida Automation offer certified refurbished units with a 12-month warranty. Verify compatibility with your system before purchase 3.

- ABB Support: Global technical support is available for configuration guidance, firmware updates, and lifecycle management. The PDP22-FBP is part of ABB’s FBP ecosystem, which includes migration paths to newer technologies like Ethernet/IP and PROFINET 110.

Caution

-

Protocol Limitations:

When used with Siemens S7-300 PLCs, the PDP22-FBP may restrict communication to 4 bytes due to differences in PROFIBUS DP profile implementation. Consider alternative modules (e.g., PDQ22) for multi-device expansion 13. -

Power Supply Verification:

Ensure the module is powered by 24V DC to avoid damage. Some third-party sources incorrectly list 240V AC, which is incompatible 46. -

Cable Integrity:

Faulty cabling accounts for 80% of PROFIBUS communication issues. Use ABB’s pre-tested FBP cables and check for loose connections or missing terminal resistors 912.

Product Assurance

The PDP22-FBP undergoes rigorous testing to meet IEC 61131-2 and UL 508 standards. ABB’s global logistics network ensures fast delivery, with priority handling for urgent orders. For compatibility with specific devices (e.g., UMC22 firmware versions), consult ABB’s documentation or contact their support team at +41 79 818 33 33 412.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com