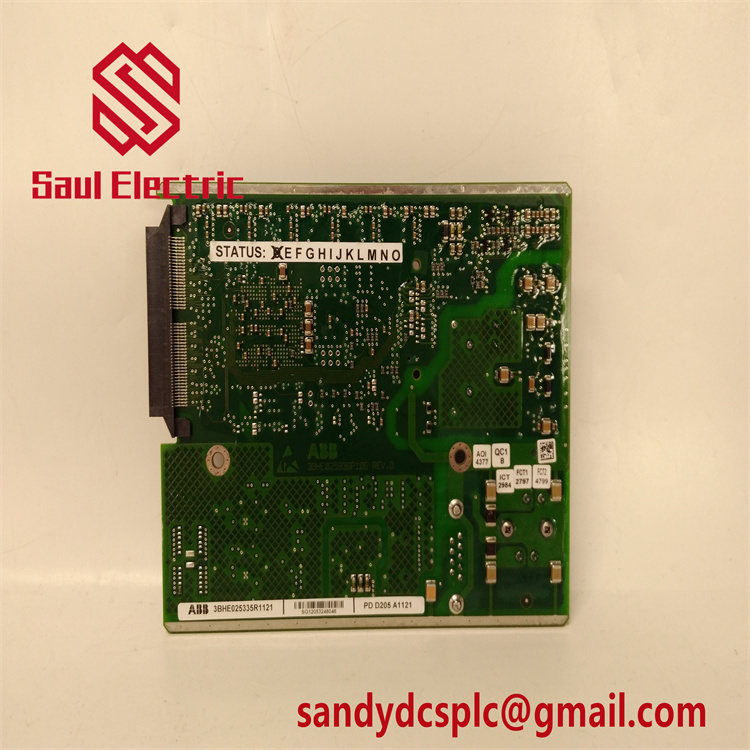

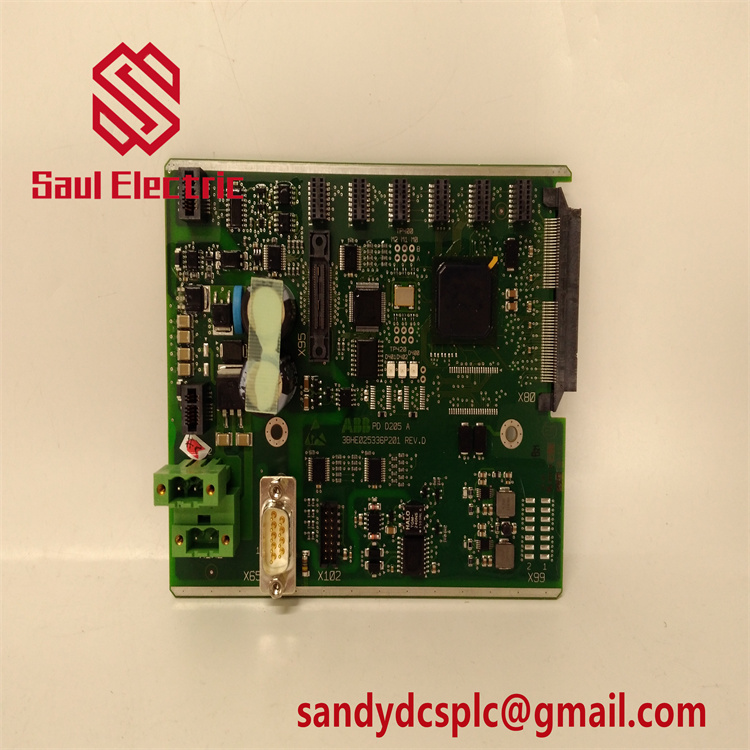

Description

The ABB PDD200A101 is a high-performance industrial control module designed for mission-critical automation systems, combining advanced signal conditioning, real-time data processing, and multi-protocol communication capabilities. While official ABB documentation for this specific model is limited, available information suggests it belongs to ABB’s AC 800PEC series, aligning with previous products like the PCD244A101 .

Key Features and Applications

-

Multi-Protocol Communication:

Supports Modbus RTU, Profibus DP, Ethernet/IP, and CAN, enabling seamless integration with distributed control systems (DCS) and third-party devices. This flexibility is critical for retrofitting legacy systems while ensuring compatibility with modern platforms like ABB’s System 800xA . -

High-Speed Data Processing:

Equipped with a ARM Cortex-A8 600 MHz processor and 512 MB RAM/512 MB Flash memory, the module executes control logic and data acquisition tasks with sub-microsecond precision. This makes it suitable for applications requiring real-time response, such as turbine speed control and chemical reactor optimization . -

Industrial-Grade Durability:

Features a conformal-coated PCB and IP67-rated enclosure, ensuring reliable operation in extreme temperatures (-40°C to +85°C) and harsh environments like offshore platforms or desert refineries. Its rugged design resists dust, oil mist, and electromagnetic interference (EMI) . -

Flexible I/O Configuration:

Offers 32 Digital Inputs/32 Digital Outputs and 8 Relay Output Channels, providing versatile connectivity for complex processes. This includes monitoring pressure sensors in oil refineries or controlling conveyor systems in automotive assembly lines . -

Hot-Swappable Design:

Supports online maintenance without system downtime, reducing operational disruptions. This is particularly valuable in continuous production environments, such as water treatment plants or power generation facilities .

Technical Specifications (Based on Similar Models)

| Parameter | Estimated Value |

|---|---|

| Product Type | Terminal Card Module (TCM) |

| Processor | ARM Cortex-A8 600 MHz (similar to PCD244A101) |

| Communication Protocols | Modbus RTU, Profibus DP, Ethernet/IP, CAN |

| I/O Interfaces | 32 DI/32 DO, 8 Relay Outputs |

| Power Supply | 24V DC (±10%) |

| Operating Temperature | -40°C to +85°C |

| Enclosure Rating | IP67 |

Application Areas

- Power Generation: Controls turbine synchronization and grid stability in thermal, nuclear, and renewable energy plants.

- Oil & Gas: Monitors wellhead pressure and gas compression systems in offshore platforms.

- Industrial Manufacturing: Drives conveyor systems and quality assurance equipment in automotive and food processing plants.

- Water Treatment: Manages pump networks and chemical dosing systems in wastewater treatment facilities .

Availability and Support

While the PDD200A101 is not explicitly listed in ABB’s current product portfolio, refurbished units may be available through certified channels. ABB’s global technical support network offers 24/7 assistance, including remote diagnostics and customized migration strategies for legacy systems. Refurbished modules undergo rigorous testing to meet original specifications and come with a 12-month warranty .

Caution

Due to limited official documentation, verifying compatibility with specific control systems (e.g., AC 800PEC backplanes) is essential. For critical applications, consult ABB’s customer support or authorized distributors to confirm technical details and procurement options.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com