Description

Application Scenarios

In the oil and gas industry, the ABB PCD235C101 3BHE057901R0101 is used for process control in refineries. It manages critical functions such as flow regulation, temperature control, and safety interlocks. For example, in a crude oil distillation unit, the PLC precisely controls valve positions based on real-time sensor data to optimize separation efficiency and ensure product quality.

PCD235C101

Installation and Maintenance

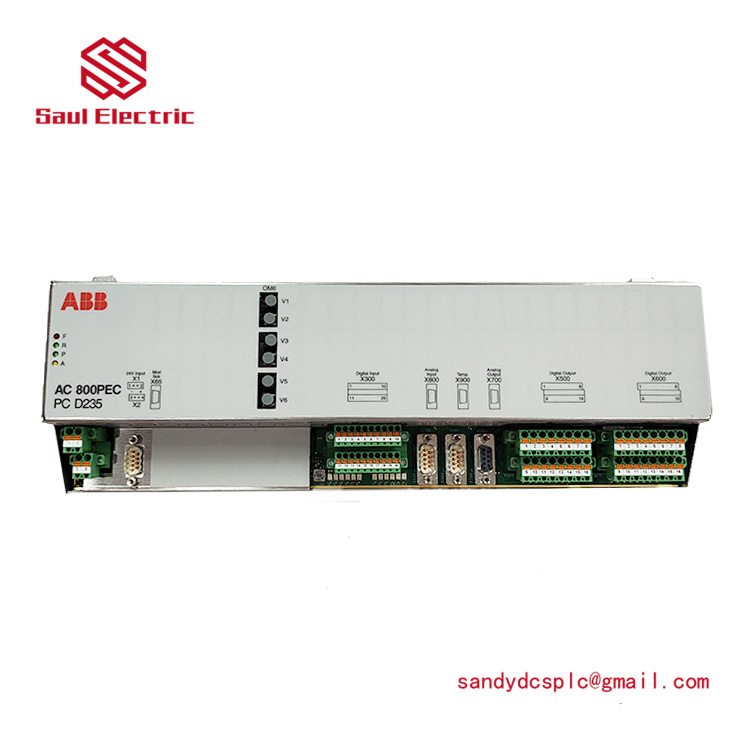

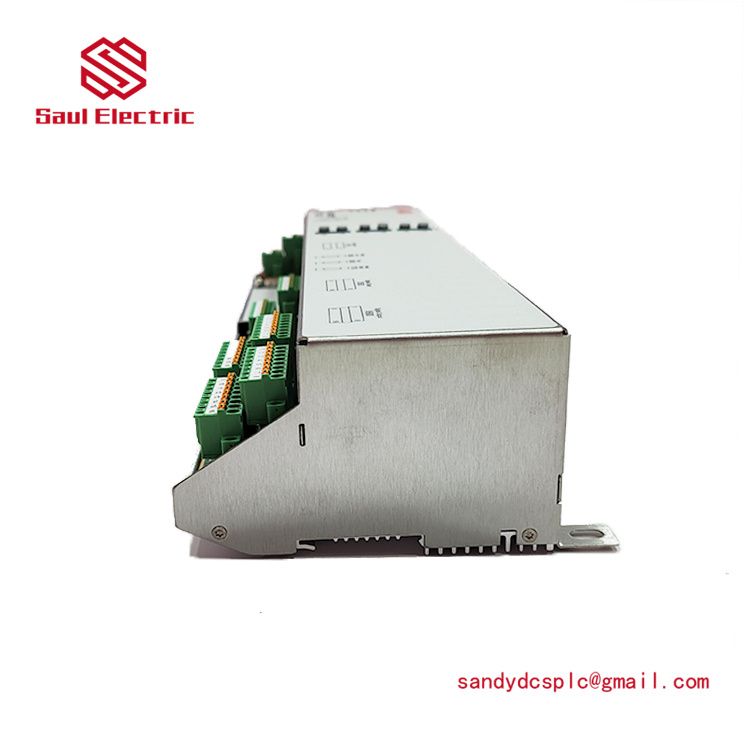

When installing the ABB PCD235C101 3BHE057901R0101, ensure the environment meets the PLC’s operating requirements. The installation location should be well-ventilated to prevent overheating, with minimal dust and vibration to prolong component life. Secure the PLC to a standard 35mm DIN rail using the included mounting hardware. Verify that the 24VDC power supply is stable and properly fused to prevent damage to the PLC. All I/O wiring should be done with shielded cables to minimize electrical interference, and connections must be tight to ensure reliable signal transmission.

PCD235C101

Key Features and Benefits

The ABB PCD235C101 3BHE057901R0101 offers exceptional performance through its high-speed 32-bit RISC processor, capable of executing complex control tasks with minimal latency. This makes it ideal for applications requiring precise timing, such as assembly line synchronization in automotive manufacturing. The PLC’s extensive I/O expansion capabilities allow it to accommodate up to 256 digital and 64 analog points, providing flexibility for large-scale automation projects.

PCD235C101

ABB HENF442581R1 O3EC PLC Module Via FEDEX/DHL

ABB O3ED Controller Module card – PLC/DCS

ABB HENF318176R1 O3EEb PLC Module Via FEDEX/DHL

ABB O3EGb HENF315118R2 DCS、PLC Module

O3EHa HENF315087R2 ABB analog module

ABB HENF452777R3 O3EId PLC Module Via FEDEX/DHL

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com