Description

Product Overview

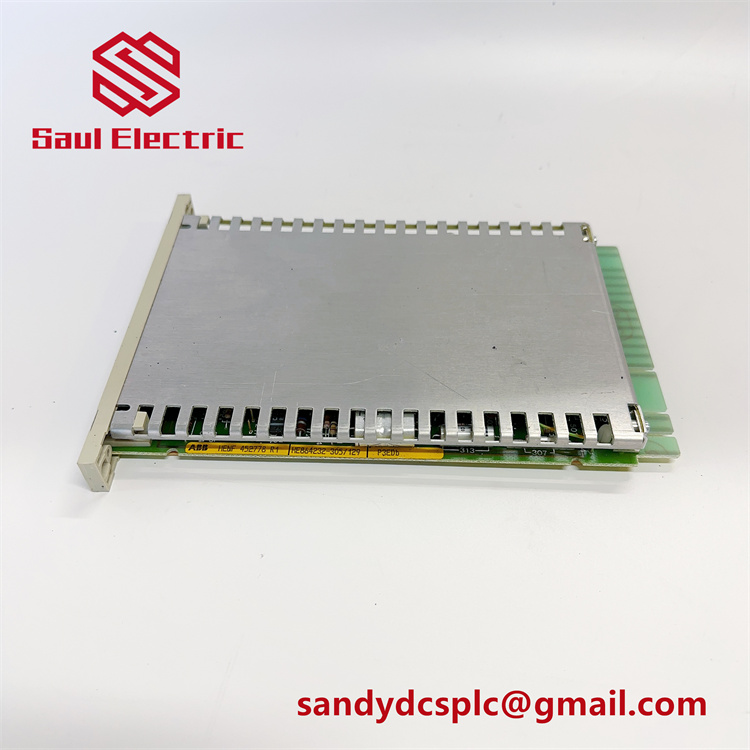

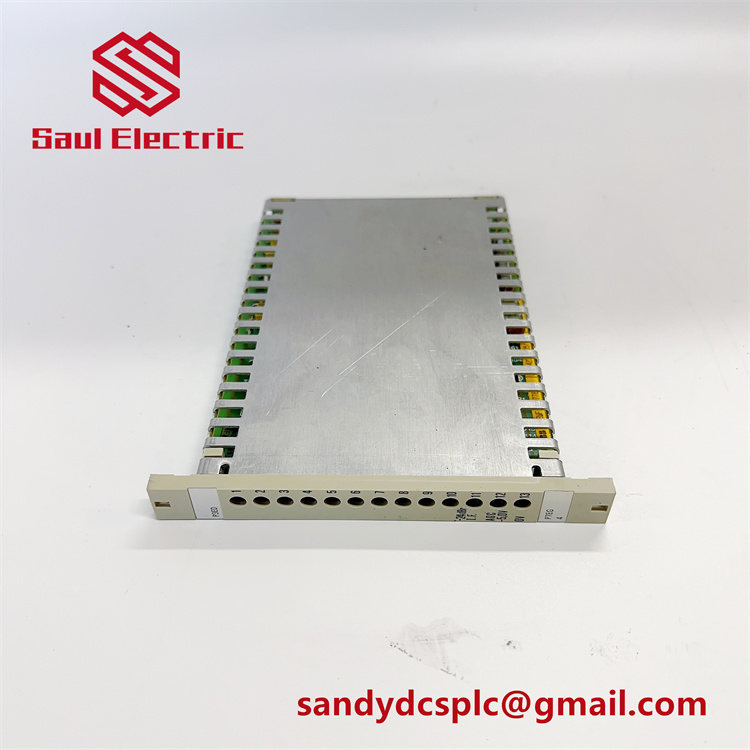

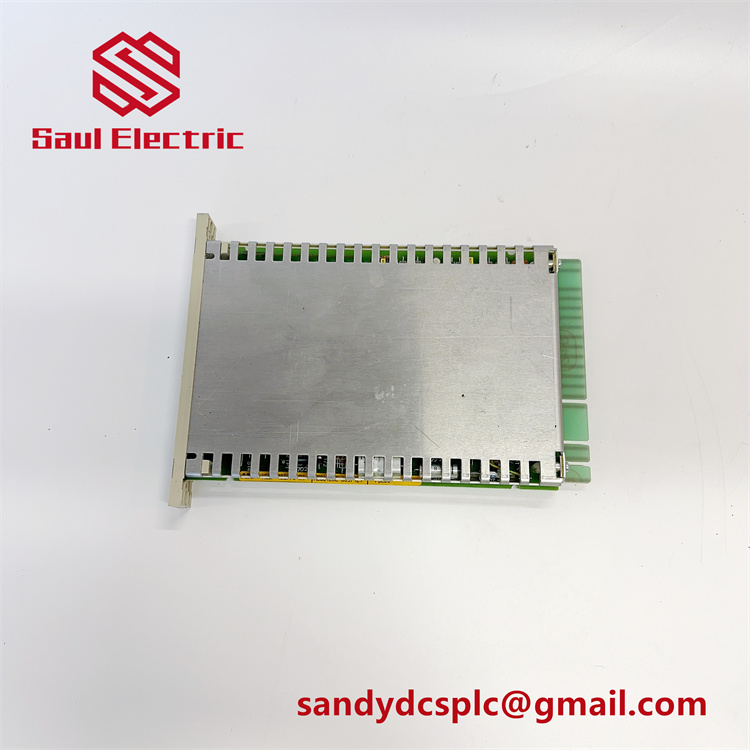

The ABB P8151B is a high-reliability unit processor module engineered for mission-critical industrial automation applications, specifically designed to deliver robust control and redundancy in safety-critical environments. Belonging to ABB’s ConTRAC series (formerly ICS Triplex), this module integrates triple modular redundancy (TMR) architecture to ensure continuous operation even in the event of single-point failures, making it ideal for applications where downtime is unacceptable, such as oil & gas, power generation, and chemical processing.

Designed to handle complex control algorithms and real-time data processing, the ABB P8151B features a high-performance CPU capable of executing logic, sequential, and analog control tasks with sub-microsecond precision. Its TMR architecture includes three independent processing channels that continuously compare outputs, ensuring fault detection and automatic isolation of faulty components. This redundancy mechanism, combined with hot-swappable design, allows for online maintenance without disrupting system operations. The module supports multiple industrial communication protocols (e.g., Profibus DP, Ethernet/IP, Modbus TCP), enabling seamless integration with distributed control systems (DCS), programmable logic controllers (PLCs), and third-party devices.

Built for industrial durability, the ABB P8151B incorporates a conformal-coated PCB and IP20-rated enclosure to resist dust, moisture, and electromagnetic interference (EMI). It operates across a wide temperature range (-40°C to +70°C) and complies with international safety standards (e.g., IEC 61508, SIL 3), ensuring reliable performance in harsh offshore platforms, refineries, and nuclear facilities. While no longer in active production, the module remains a trusted solution for legacy systems, backed by ABB’s global technical support and certified refurbishment services.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB P8151B |

| Manufacturer | ABB |

| Product Type | High-Reliability Unit Processor Module |

| Redundancy Architecture | Triple Modular Redundancy (TMR) |

| Processing Power | 160 MHz RISC Processor |

| Memory | 512 KB SRAM, 2 MB Flash Memory |

| Communication Protocols | Profibus DP, Ethernet/IP, Modbus TCP, DeviceNet |

| I/O Interfaces | 8 x Digital Input/Output (可配置) |

| Isolation | 2500 V DC between channels |

| Operating Temperature | -40°C to +70°C |

| Humidity | 0–95% non-condensing |

| Physical Dimensions | 125 mm (W) × 150 mm (H) × 80 mm (D) |

| Weight | 0.9 kg |

| Certifications | IEC 61508 SIL 3, CE, UL 508, RoHS compliant |

Key Features and Advantages

Triple Modular Redundancy (TMR):

The ABB P8151B’s TMR architecture ensures fault tolerance by replicating critical processing functions across three independent channels. Outputs are continuously voted to detect discrepancies, with faulty channels automatically isolated and replaced by healthy ones. This redundancy mechanism eliminates single points of failure, making the module suitable for applications like emergency shutdown systems (ESD) in offshore platforms and nuclear power plants 3.

The ABB P8151B’s TMR architecture ensures fault tolerance by replicating critical processing functions across three independent channels. Outputs are continuously voted to detect discrepancies, with faulty channels automatically isolated and replaced by healthy ones. This redundancy mechanism eliminates single points of failure, making the module suitable for applications like emergency shutdown systems (ESD) in offshore platforms and nuclear power plants 3.

High-Speed Processing:

Equipped with a 160 MHz RISC processor, the module executes control logic and data acquisition tasks with sub-microsecond precision, supporting real-time applications such as turbine speed control and chemical reactor optimization. Its 512 KB SRAM and 2 MB flash memory enable storage of complex control algorithms and historical data for predictive maintenance 3.

Equipped with a 160 MHz RISC processor, the module executes control logic and data acquisition tasks with sub-microsecond precision, supporting real-time applications such as turbine speed control and chemical reactor optimization. Its 512 KB SRAM and 2 MB flash memory enable storage of complex control algorithms and historical data for predictive maintenance 3.

Flexible Communication:

The ABB P8151B supports multiple industrial protocols, including Profibus DP, Ethernet/IP, and Modbus TCP, allowing seamless integration with legacy and modern control systems. This flexibility simplifies retrofitting of existing plants while enabling future-proofing through compatibility with ABB’s System 800xA and other open-platform solutions 27.

The ABB P8151B supports multiple industrial protocols, including Profibus DP, Ethernet/IP, and Modbus TCP, allowing seamless integration with legacy and modern control systems. This flexibility simplifies retrofitting of existing plants while enabling future-proofing through compatibility with ABB’s System 800xA and other open-platform solutions 27.

Industrial-Grade Durability:

Designed for harsh environments, the module features a conformal-coated PCB and IP20 enclosure to resist dust, oil mist, and humidity. Its wide operating temperature range (-40°C to +70°C) and rugged thermal management ensure stable performance in extreme climates, such as Arctic oil fields or desert refineries 3.

Designed for harsh environments, the module features a conformal-coated PCB and IP20 enclosure to resist dust, oil mist, and humidity. Its wide operating temperature range (-40°C to +70°C) and rugged thermal management ensure stable performance in extreme climates, such as Arctic oil fields or desert refineries 3.

Hot-Swappable Design:

The ABB P8151B supports online replacement of faulty modules without system downtime, reducing maintenance costs and improving operational efficiency. This feature is critical for applications like continuous chemical production lines, where even short interruptions can lead to significant losses 3.

The ABB P8151B supports online replacement of faulty modules without system downtime, reducing maintenance costs and improving operational efficiency. This feature is critical for applications like continuous chemical production lines, where even short interruptions can lead to significant losses 3.

Application Areas

Oil & Gas:

In offshore platforms and refineries, the ABB P8151B monitors and controls critical processes such as wellhead pressure regulation, gas compression, and fire/smoke detection. Its TMR architecture ensures reliable operation in high-risk environments, while redundant communication interfaces enable integration with distributed safety systems 2324.

In offshore platforms and refineries, the ABB P8151B monitors and controls critical processes such as wellhead pressure regulation, gas compression, and fire/smoke detection. Its TMR architecture ensures reliable operation in high-risk environments, while redundant communication interfaces enable integration with distributed safety systems 2324.

Power Generation:

The module is used in thermal and nuclear power plants for turbine speed control, generator protection, and boiler combustion optimization. Its high-speed processing and SIL 3 certification make it ideal for managing emergency shutdown systems and ensuring grid stability 322.

The module is used in thermal and nuclear power plants for turbine speed control, generator protection, and boiler combustion optimization. Its high-speed processing and SIL 3 certification make it ideal for managing emergency shutdown systems and ensuring grid stability 322.

Chemical Processing:

In petrochemical and pharmaceutical plants, the ABB P8151B drives batch reactor control, distillation column monitoring, and quality assurance systems. Its TMR redundancy and real-time data processing capabilities help maintain product consistency and comply with strict regulatory standards 23.

In petrochemical and pharmaceutical plants, the ABB P8151B drives batch reactor control, distillation column monitoring, and quality assurance systems. Its TMR redundancy and real-time data processing capabilities help maintain product consistency and comply with strict regulatory standards 23.

Transportation:

The module supports railway signaling systems and metro train control, ensuring safe and reliable operation of mass transit networks. Its fault-tolerant design and wide temperature range make it suitable for both indoor and outdoor installations 21.

The module supports railway signaling systems and metro train control, ensuring safe and reliable operation of mass transit networks. Its fault-tolerant design and wide temperature range make it suitable for both indoor and outdoor installations 21.

Water & Wastewater Treatment:

In water treatment plants, the ABB P8151B manages pump control, chemical dosing, and effluent quality monitoring. Its robust communication capabilities enable centralized supervision of distributed water stations, optimizing resource allocation and reducing operational costs 24.

In water treatment plants, the ABB P8151B manages pump control, chemical dosing, and effluent quality monitoring. Its robust communication capabilities enable centralized supervision of distributed water stations, optimizing resource allocation and reducing operational costs 24.

Related Products

- ABB T8151B: Communication interface module supporting Ethernet/IP and Profibus DP, designed for seamless integration with the P8151B in hybrid control systems 27.

- ABB AC800M Controller: Modern modular DCS controller with TMR option, offering advanced diagnostics and scalability for process industry applications 22.

- ABB P4LQA HENF209736R0003: 16-channel analog input module with 16-bit resolution, ideal for high-precision signal conditioning in conjunction with the P8151B 3.

- ABB P5EAa HENF206350R2: 15 A power supply module with 94% efficiency, ensuring stable power delivery for the P8151B and other I/O modules 3.

- ABB TB821: Modbus RTU-to-Ethernet gateway, enabling legacy system integration with modern PLCs and cloud-based platforms 3.

Installation and Maintenance

Installation Preparation:

Before installing the ABB P8151B, verify compatibility with your control system’s backplane and power requirements. Secure the module to a 35 mm DIN rail using the included brackets, leaving 30 mm of clearance for airflow. Connect communication cables (shielded twisted pair) to the module’s Profibus DP or Ethernet ports, following ABB’s wiring diagrams for proper grounding. For redundancy setups, install a second P8151B module using ABB’s TMR synchronization kit 327.

Before installing the ABB P8151B, verify compatibility with your control system’s backplane and power requirements. Secure the module to a 35 mm DIN rail using the included brackets, leaving 30 mm of clearance for airflow. Connect communication cables (shielded twisted pair) to the module’s Profibus DP or Ethernet ports, following ABB’s wiring diagrams for proper grounding. For redundancy setups, install a second P8151B module using ABB’s TMR synchronization kit 327.

Maintenance Recommendations:

Conduct quarterly visual inspections to check for loose connections, dust accumulation, or signs of thermal stress. Clean the enclosure with a dry, anti-static cloth; avoid solvents that may damage the conformal coating. Annually verify communication integrity using ABB’s diagnostic tools, ensuring protocol compliance and data transmission accuracy. While firmware is factory-optimized, consult ABB support for updates when integrating with new system versions. Maintain at least one spare module on-site to address unexpected failures, leveraging ABB’s global inventory for rapid replacement 319.

Conduct quarterly visual inspections to check for loose connections, dust accumulation, or signs of thermal stress. Clean the enclosure with a dry, anti-static cloth; avoid solvents that may damage the conformal coating. Annually verify communication integrity using ABB’s diagnostic tools, ensuring protocol compliance and data transmission accuracy. While firmware is factory-optimized, consult ABB support for updates when integrating with new system versions. Maintain at least one spare module on-site to address unexpected failures, leveraging ABB’s global inventory for rapid replacement 319.

Product Assurance

The ABB P8151B is backed by a 12-month warranty covering defects in materials and workmanship. ABB’s global service network provides 24/7 technical support, including remote diagnostics, on-site commissioning, and customized migration strategies for legacy systems. While the module is no longer in active production, certified refurbished units are available through ABB’s authorized distributors, ensuring reliable availability and fast delivery (3-day turnaround for urgent orders) 1925. Rigorously tested to international standards (IEC 61508, IEC 60068), the P8151B delivers proven performance in harsh industrial environments, making it a trusted choice for automation professionals worldwide.

ABB HENF442581R1 O3EC PLC Module Via FEDEX/DHL

ABB O3ED Controller Module card – PLC/DCS

ABB HENF318176R1 O3EEb PLC Module Via FEDEX/DHL

ABB O3EGb HENF315118R2 DCS、PLC Module

O3EHa HENF315087R2 ABB analog module

ABB HENF452777R3 O3EId PLC Module Via FEDEX/DHL

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com