Description

Product Overview

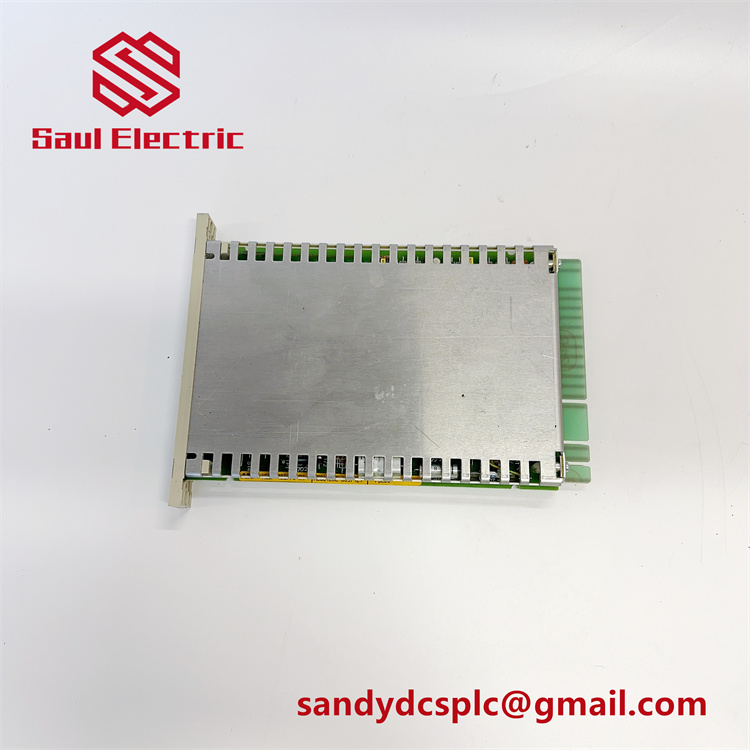

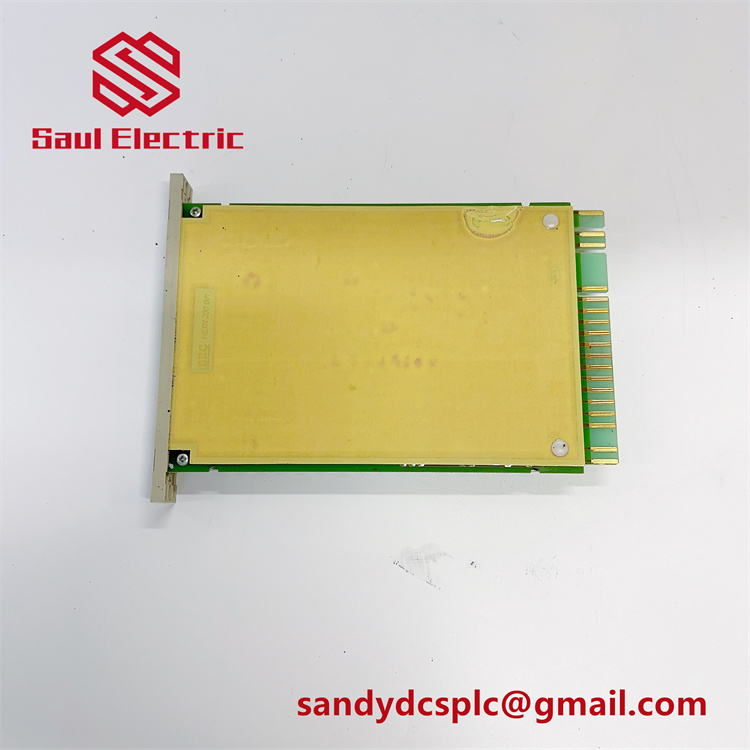

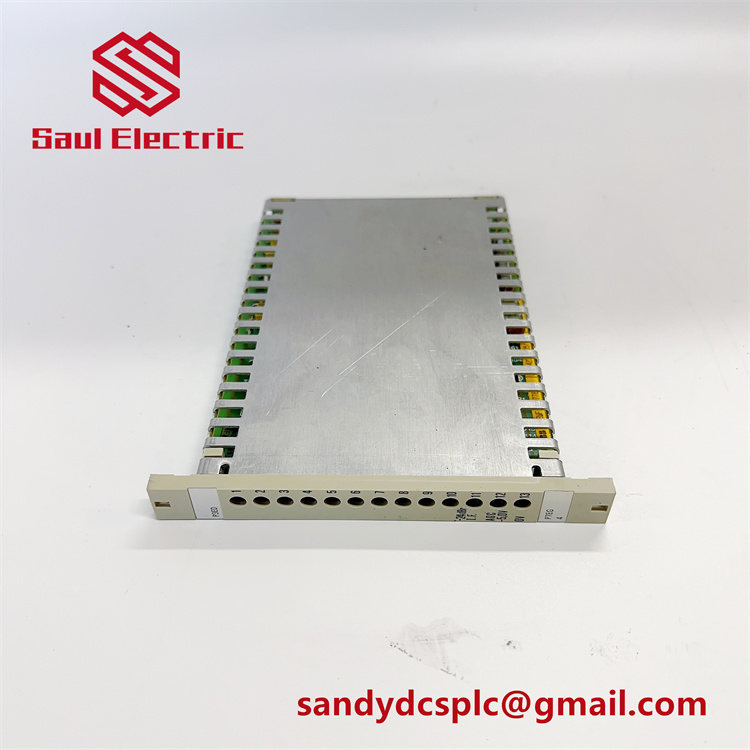

The ABB P4LQA HENF209736R0003 is a high-precision analog input module designed for industrial automation systems, specializing in seamless integration with ABB’s S800 I/O distributed control system (DCS) and System 800xA platform. Engineered to convert analog signals from field sensors into digital data for centralized processing, this module supports 8-channel input with 16-bit resolution, ensuring precise measurement of parameters like temperature, pressure, and flow rate in mission-critical applications. With galvanic isolation (2500 V DC) and wide signal compatibility (4–20 mA, 0–10 V, RTD, thermocouple), the P4LQA HENF209736R0003 balances accuracy with rugged durability for harsh industrial environments such as power plants, oil refineries, and chemical processing facilities.

Featuring wide input voltage compatibility (24 V DC ±20%) and advanced signal conditioning, the module ensures stable operation across -40°C to +70°C. Its IP20-rated enclosure with conformal coating protects against dust, moisture, and electromagnetic interference (EMI), while the hot-swappable design and 35 mm DIN rail mounting simplify installation and maintenance. The P4LQA HENF209736R0003 integrates seamlessly with ABB’s modular I/O architecture, enabling real-time data acquisition and predictive maintenance via Profibus DP or EtherNet/IP communication protocols. With a 12-month warranty and global technical support, this module combines high-performance sensing with ABB’s renowned reliability to optimize industrial process control.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB P4LQA HENF209736R0003 |

| Manufacturer | ABB |

| Product Type | High-Precision Analog Input Module |

| Input Channels | 8 (configurable: 4–20 mA, 0–10 V, RTD, thermocouple) |

| Resolution | 16-bit (±0.05% of full scale) |

| Signal Isolation | 2500 V DC galvanic isolation per channel |

| Input Voltage | 24 V DC ±20% (power supply) |

| Power Consumption | <5 W |

| Communication Protocols | Profibus DP, EtherNet/IP (via gateway) |

| Operating Temperature | -40°C to +70°C |

| Humidity | 0–95% non-condensing |

| Dimensions | 100 mm (W) × 150 mm (H) × 80 mm (D) |

| Weight | 0.5 kg |

| Certifications | CE, UL 508, IEC 61131-2, RoHS compliant |

Key Features and Advantages

Ultra-Precise Signal Conversion:

- The 16-bit resolution ensures measurement accuracy within ±0.05% of full scale, critical for applications like semiconductor wafer temperature control or pharmaceutical dosing systems. Support for RTD/thermocouple inputs eliminates the need for external signal conditioners, reducing system complexity.

Rugged Industrial Design:

- IP20-rated enclosure with conformal coating withstands harsh conditions, including dust, vibration, and chemical mist in oil refineries or mining sites. The -40°C to +70°C temperature range enables operation in extreme environments without performance degradation.

Flexible Integration:

- Compatible with ABB’s S800 I/O modules (e.g., P3EDb power supply, P3ECa controller) and third-party systems via Modbus RTU (with TB821 adapter). Configurable via ABB’s Control Builder M software for custom signal scaling and fault handling.

Maintenance Efficiency:

- Hot-swappable design allows module replacement during system operation, minimizing downtime in 24/7 processes. Front-panel LED indicators for channel status and power health enable quick diagnostics, reducing mean time to repair (MTTR).

Application Areas

Power Generation:

- Monitors turbine blade temperatures via thermocouples and boiler pressure via 4–20 mA transmitters in thermal power plants. Supports redundant control systems for emergency shutdown protocols.

Oil & Gas:

- Processes wellhead pressure signals and flow rates in offshore platforms, withstanding saltwater corrosion and high vibration. Enables real-time data transmission to SCADA systems for production optimization.

Manufacturing:

- Measures conveyor belt speeds and robotic arm positions in automotive assembly lines, ensuring synchronization and quality control. Integrates with System 800xA for predictive maintenance of production equipment.

Water Treatment:

- Converts pH sensor (0–10 V) and level transmitter (4–20 mA) signals for centralized monitoring in wastewater treatment plants. Supports remote configuration for adaptive chemical dosing.

Related Products

- ABB S800 I/O System: Modular platform compatible with the P4LQA HENF209736R0003, offering scalable I/O expansion for complex control systems.

- ABB P3EDb HENF452778R1: 15 A power supply module, essential for stable operation of the P4LQA in high-density I/O configurations.

- ABB P4LQB HENF209737R0001: 16-channel analog input variant, ideal for large-scale process monitoring requiring increased channel density.

- ABB TB821: Modbus RTU-to-Ethernet gateway, enabling the P4LQA to communicate with legacy PLCs in hybrid automation systems.

- ABB BRC410: Bridge controller supporting S800 I/O integration, often paired with the P4LQA for centralized data processing.

Installation and Maintenance

Installation Preparation:

- DIN Rail Mounting: Secure the P4LQA HENF209736R0003 to a 35 mm DIN rail using captive screws, leaving 25 mm clearance for airflow. Connect 24 V DC power and field signals using shielded cables (e.g., ABB NKAS01-15) to minimize EMI.

- Configuration: Use ABB’s Control Builder M to set input types (e.g., RTD Pt100, thermocouple K-type) and scaling parameters. Verify signal integrity with a multimeter before commissioning.

Maintenance Recommendations:

- Periodic Checks: Quarterly visual inspections for loose connections or dust accumulation. Clean the enclosure with a dry, anti-static cloth.

- Calibration: Annually calibrate input channels using a certified signal generator, ensuring ±0.05% accuracy. ABB’s calibration services comply with ISO 17025 standards.

- Firmware Updates: Regularly update firmware via System 800xA to support new sensor types or diagnostic features. Maintain at least one spare module for critical applications.

Product Assurance

The ABB P4LQA HENF209736R0003 is backed by a 12-month warranty covering manufacturing defects, with extended warranties available for mission-critical applications. ABB’s global service network provides 24/7 technical support, including remote configuration assistance and on-site repairs. Stocked in ABB’s regional distribution hubs, the module ensures 3-day delivery for urgent orders, minimizing production downtime. Rigorously tested to IEC 61000-6-2 (EMC) and IEC 60068-2-14 (thermal cycling), the P4LQA HENF209736R0003 delivers proven reliability in harsh industrial environments, making it a trusted choice for automation professionals.

ABB HENF442581R1 O3EC PLC Module Via FEDEX/DHL

ABB O3ED Controller Module card – PLC/DCS

ABB HENF318176R1 O3EEb PLC Module Via FEDEX/DHL

ABB O3EGb HENF315118R2 DCS、PLC Module

O3EHa HENF315087R2 ABB analog module

ABB HENF452777R3 O3EId PLC Module Via FEDEX/DHL

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com