Description

Product Overview

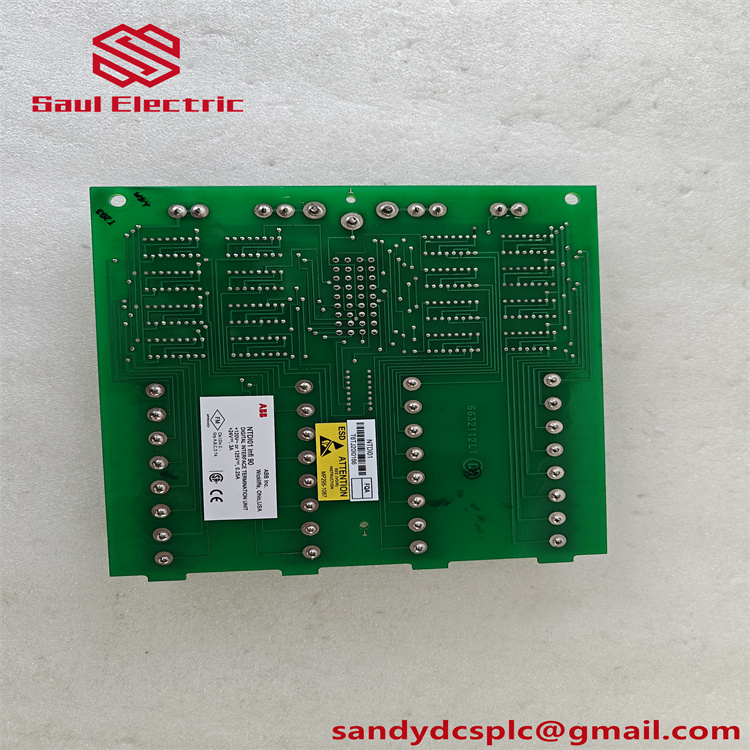

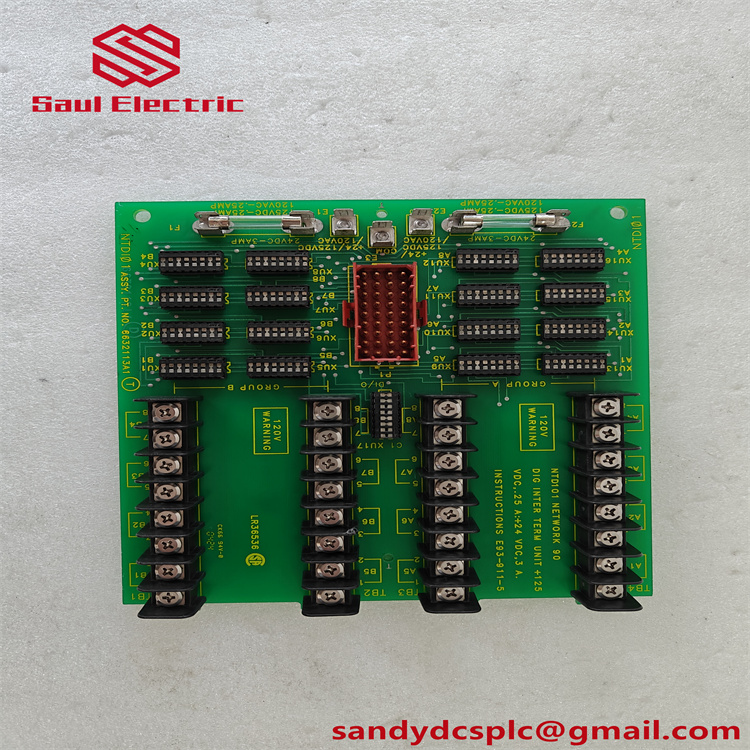

The ABB NTR002-A is a 2-channel temperature sensor interface module designed for ABB’s S800 I/O distributed control system (DCS). Serving as a critical interface between RTD/thermocouple sensors and control systems, the ABB NTR002-A enables precise temperature measurement and signal conditioning for industrial automation applications. With support for -200°C to 1800°C temperature ranges and 0.1°C accuracy, this module ensures reliable data acquisition in extreme environments, including power plants, oil refineries, and chemical processing facilities 26.

Engineered with a modular design, the ABB NTR002-A integrates seamlessly with ABB’s S800 I/O platform, supporting direct connection to HR Series controllers and BRC300/400/410 bridge controllers for advanced process control 16. Its IP20-rated enclosure with conformal coating protects against dust, moisture, and electromagnetic interference (EMI), while the 24 V DC power supply ensures stable operation in harsh industrial settings 15. By providing galvanic isolation and surge protection, the ABB NTR002-A minimizes signal distortion and enhances system stability, reducing downtime in mission-critical processes.

As part of ABB’s industrial automation portfolio, the ABB NTR002-A plays a pivotal role in modernizing control systems by enabling real-time temperature monitoring and predictive maintenance. Its DIN rail mounting and hot-swappable design streamline installation and maintenance, making it a cost-effective solution for industries requiring high-precision temperature control. With global technical support and a 12-month warranty, the ABB NTR002-A combines cutting-edge technology with ABB’s renowned reliability to meet the demands of industrial automation 615.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB NTR002-A |

| Manufacturer | ABB |

| Product Type | 2-Channel Temperature Sensor Interface Module |

| Sensor Types | RTD (PT100/PT1000), Thermocouple (K, J, T, E, S, B, R) |

| Temperature Range | -200°C to 1800°C |

| Accuracy | ±0.1°C |

| Resolution | 16-bit |

| Power Supply | 24 V DC ±10% |

| Physical Dimensions | 100 mm (W) × 50 mm (H) × 30 mm (D) |

| Weight | 1.0 kg |

| Operating Temperature | -20°C to +60°C |

| Humidity | 0–95% non-condensing |

| Mounting | 35 mm DIN rail |

| Certifications | CE, UL 508, IEC 61131-2 (EMC) |

| Signal Isolation | 2500 V DC galvanic isolation |

Key Features and Advantages

Wide Temperature Range: The ABB NTR002-A supports -200°C to 1800°C measurements, making it suitable for cryogenic processes (e.g., liquefied natural gas) and high-temperature applications (e.g., boiler furnaces) 26. Its 0.1°C accuracy ensures precise temperature profiling for quality control and safety-critical systems.

Rugged Industrial Design: Built with an IP20-rated enclosure and conformal coating, the ABB NTR002-A withstands harsh conditions, including dust, humidity, and EMI. Its extended operating temperature range (-20°C to +60°C) and 2500 V DC galvanic isolation protect against electrical noise and ground loops, ensuring stable data transmission 15.

Modular System Integration: Compatible with ABB’s S800 I/O platform and HR Series controllers, the ABB NTR002-A supports seamless integration with legacy and modernized DCS architectures. It also enables hybrid control systems via Modbus RTU connectivity through gateway modules like the ABB TB821 16.

Diagnostic Capabilities: The module includes real-time status LEDs for signal integrity, power supply, and sensor fault detection. Built-in self-diagnostics identify open circuits, short circuits, and drift, allowing proactive maintenance to avoid unplanned downtime 6.

Ease of Maintenance: Hot-swappable design and screw-terminal connections simplify field wiring and replacement. ABB’s Control Builder M software facilitates remote configuration and firmware updates, reducing commissioning time and costs 16.

Application Areas

Power Generation: The ABB NTR002-A monitors turbine blade temperatures in thermal power plants and tracks boiler flue gas temperatures to optimize combustion efficiency. Its redundancy support ensures reliable operation in emergency shutdown systems 616.

Oil & Gas: In offshore platforms and refineries, the ABB NTR002-A processes thermocouple signals from wellhead heaters and RTD inputs from compressor bearings to detect overheating and prevent equipment failure. Its rugged design ensures durability in corrosive and high-vibration environments 215.

Water Treatment: The unit converts RTD signals from wastewater treatment tanks to standardized 4–20 mA outputs for SCADA monitoring. It also manages temperature-controlled chemical dosing systems to ensure compliance with environmental regulations 6.

Manufacturing: In semiconductor fabrication and food processing plants, the ABB NTR002-A connects RTDs to DCS controllers for precise oven temperature control and sterilization processes. Its high accuracy supports ISO 17025-compliant quality assurance protocols 15.

Related Products

- ABB NTR002: Single-channel temperature sensor interface module, ideal for applications requiring fewer channels 7.

- ABB NT R AO02-A: Communication adapter for integrating the ABB NTR002-A with legacy INFI 90 systems via Profibus DP 5.

- ABB ASI 651: 8-channel analog input module for 4–20 mA signals, complementing the ABB NTR002-A’s temperature monitoring capabilities 16.

- ABB BRC410: Bridge controller supporting S800 I/O and Modbus TCP, enabling centralized control of ABB NTR002-A modules 16.

- ABB S800 I/O System: Modular I/O platform providing scalable solutions for temperature, pressure, and flow measurement 16.

Installation and Maintenance

Installation Preparation:

- DIN Rail Mounting: Secure the ABB NTR002-A to a 35 mm DIN rail using included brackets, ensuring proper alignment with adjacent S800 I/O modules.

- Wiring: Connect RTD/thermocouple sensors to the unit’s screw terminals, following ABB’s wiring diagrams for polarity and shielded cable routing. Use NKAS01-15 shielded cables to minimize EMI 616.

- Configuration: Set sensor types (RTD/thermocouple) and temperature ranges via Control Builder M software. Verify loop power (24 V DC) and ground connections using front-panel LEDs 16.

Maintenance Recommendations:

- Hot-Swap Replacement: Replace faulty modules without system shutdown by disconnecting power, removing the old module, and inserting a new ABB NTR002-A.

- Calibration: Perform annual accuracy checks using a certified temperature calibrator, adjusting offsets as needed. ABB’s calibration tools ensure compliance with IEC 60751 standards 6.

- Firmware Updates: Regularly update firmware via Control Builder M to support new sensor types and enhance diagnostic features.

- ESD Protection: Use ABB’s Field Static Kit during handling to prevent electrostatic discharge damage to sensitive components 16.

Product Assurance

The ABB NTR002-A is backed by a 12-month warranty covering manufacturing defects, with extended warranties available for critical applications. ABB’s global service network provides 24/7 technical support for commissioning, troubleshooting, and custom integration. Stocked in ABB’s Xiamen and Singapore hubs, the ABB NTR002-A ensures fast delivery (3–5 days for Taiwan orders) and immediate replacement in case of emergencies 615.

With rigorous testing against EMC and environmental standards, the ABB NTR002-A delivers unmatched reliability in electrically noisy or extreme conditions. ABB’s commitment to quality and innovation makes it the preferred choice for industrial automation professionals seeking high-performance, future-proof solutions.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com